Hello,

Just after some help laying a concrete slab, I've been looking over old posts but a few things don't seem to have been covered.

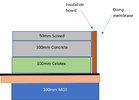

I have the basics - Compact ground, 100mm Hardcore, 25mm Sand, DPM, 100mm Concrete, 75mm Inulation & finish with 25mm screed. It's just some of the practicals I'm not sure about;

1. I keep reading about HAVING to lap the DPM into the DPC. In this case the DPC is bitumen and strangely is below the existing slab level ?? I really don't want to start cutting into 100 year old bitumen joints, would Building Control allow me to just cut the DPM membrane at floor level or tuck it in somewhere ?

2. Stairs. When I dig down, how do I support the stairs at the bottom, do I even need to ?

3. Can I pour the slab in two seperate pieces ( the kitchen is already concrete ) with a break betwen them, I mean one slab for living room and another for dining area, maybe have some insulation board seperating them where the door threashold is ?

4. On the day of the pour, I was gonna stump up the few hundred quid and have it pumped in, about 3m3 for living room and 2m3 for dining area. I've never done concrete before, Is the tamping and levelling easy enough or should I see if I can get a builder for this ?

Just after some help laying a concrete slab, I've been looking over old posts but a few things don't seem to have been covered.

I have the basics - Compact ground, 100mm Hardcore, 25mm Sand, DPM, 100mm Concrete, 75mm Inulation & finish with 25mm screed. It's just some of the practicals I'm not sure about;

1. I keep reading about HAVING to lap the DPM into the DPC. In this case the DPC is bitumen and strangely is below the existing slab level ?? I really don't want to start cutting into 100 year old bitumen joints, would Building Control allow me to just cut the DPM membrane at floor level or tuck it in somewhere ?

2. Stairs. When I dig down, how do I support the stairs at the bottom, do I even need to ?

3. Can I pour the slab in two seperate pieces ( the kitchen is already concrete ) with a break betwen them, I mean one slab for living room and another for dining area, maybe have some insulation board seperating them where the door threashold is ?

4. On the day of the pour, I was gonna stump up the few hundred quid and have it pumped in, about 3m3 for living room and 2m3 for dining area. I've never done concrete before, Is the tamping and levelling easy enough or should I see if I can get a builder for this ?

Attachments

Last edited: