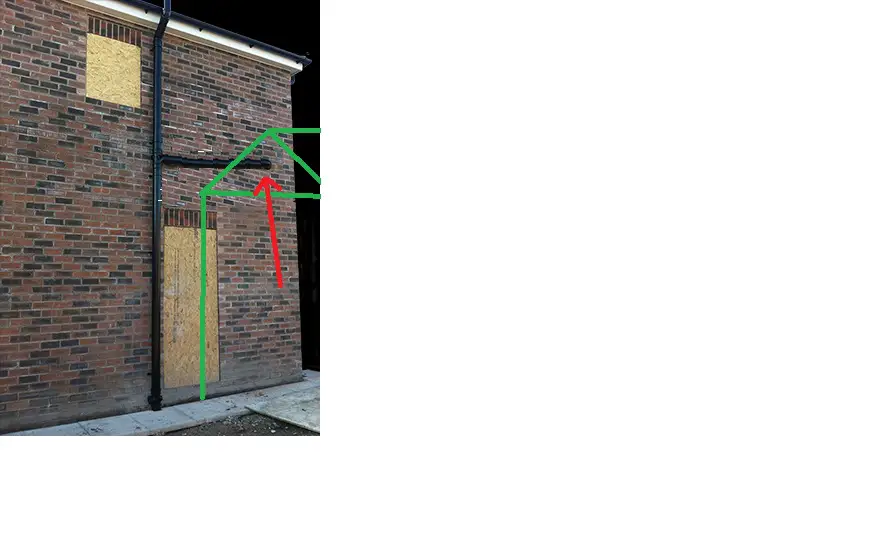

I'm going to have a 110 mm soil pipe emerge from a wall within a kitchen roof cavity (indicated in green in image), this then emerges from kitchen roof and connects to external stack.

I presume there's any point in having an access port on the 92.5 degree bend (indicated by red arrow) since there's no hatch in the kitchen ceiling to access it. The branch section at the stack will have an access port in any case, so I hope this would be sufficient.

I had intended to use a push-fit single socket bend at this point (pic A below), however after learning on the forum recently that weld-fit fittings are best to use in concealed areas instead of push-fit fittings, I'm not thinking it would be best to use a solvent-weld bend instead (pic B below). Pic B shows a double socket bend since I think it would have to be this to weld at both ends of the bend.

I'd appreciate any comments on this, in that, if you think this is the correct way to go. Thanks!

A)

http://tinyurl.com/yaastlbz

B)

I presume there's any point in having an access port on the 92.5 degree bend (indicated by red arrow) since there's no hatch in the kitchen ceiling to access it. The branch section at the stack will have an access port in any case, so I hope this would be sufficient.

I had intended to use a push-fit single socket bend at this point (pic A below), however after learning on the forum recently that weld-fit fittings are best to use in concealed areas instead of push-fit fittings, I'm not thinking it would be best to use a solvent-weld bend instead (pic B below). Pic B shows a double socket bend since I think it would have to be this to weld at both ends of the bend.

I'd appreciate any comments on this, in that, if you think this is the correct way to go. Thanks!

A)

http://tinyurl.com/yaastlbz

B)