- Joined

- 7 Oct 2016

- Messages

- 9

- Reaction score

- 0

- Country

Hi - we are converting our garage and I was after some advice along the way.

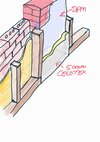

We have already poured foundations to support a wall and two windows to infill where the 2 garage doors were to the satisfaction of the building control officer. We have agreed with building control to make the external skin 2 bricks deep so that it ends up the same thickness as the existing central pier of the garage which we plan to leave alone. We will then have a 50mm air gap and stud etc.

We are unsure how we should install a cavity tray and if we in fact need one in conjunction with weep holes?

I would be very grateful for a steer on this as we have employed a great bricklayer(old skool) but he is not up to speed with current building regs…..

Thanks in advance for any assistance.

Cheers Alan

We have already poured foundations to support a wall and two windows to infill where the 2 garage doors were to the satisfaction of the building control officer. We have agreed with building control to make the external skin 2 bricks deep so that it ends up the same thickness as the existing central pier of the garage which we plan to leave alone. We will then have a 50mm air gap and stud etc.

We are unsure how we should install a cavity tray and if we in fact need one in conjunction with weep holes?

I would be very grateful for a steer on this as we have employed a great bricklayer(old skool) but he is not up to speed with current building regs…..

Thanks in advance for any assistance.

Cheers Alan

Last edited: