I'm altering stage lighting as part of a refurb and run into a silly little niggly corner.

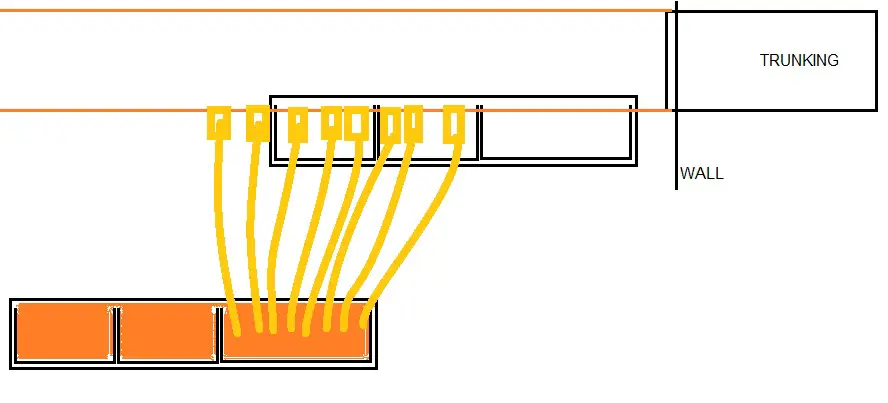

The 100x50 trunking at the top is at ceiling level, to the right is an office to which I have no access and the other side of the office is the power/dimmer cupboard. Trunking used to continue to the left [red] but has been cut of almost flush with the office wall to make way for the new hole in the wall for cable basket. Originally [red block] this was to have been some 300mm from the ceiling and office wall and my intention was the new SY lighting cables were to come through the hole and straight up, terminating in glands into the trunking [orange].

However the new hole is less than 100mm from the slab and 40mm from the wall with the top of the basket marginally higher than the bottom of the trunking [hole, basket and trunking shown in black].

It's going to be a PITA but I think the cables will loop round into the end of the trunking OK from the hole.

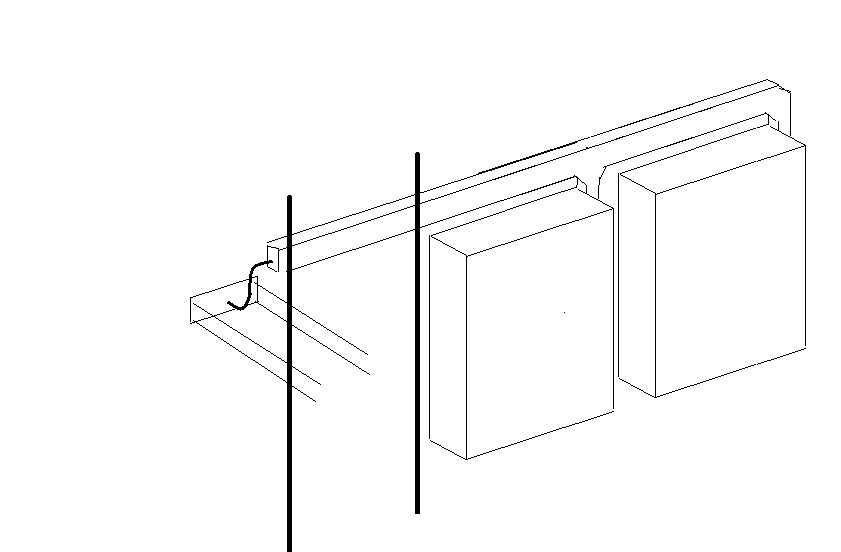

At the dimmer packs there is a large cut out [maybe 150x30mm from memory] between the vertical 50x50mm trunking and side of pack.

My question based on previous discussions is: what are peoples opinions on the best way to terminate the SY cable. At the moment I'm looking at a pigtail into the earth bar once it's inside the pack but I am struggling to find anywhere to provide any mechanical restraint.

The 2 packs, remainder of the buildings switchgear and trunking take up the height and width of the cupboard.

Access to the 100x50 trunking is restricted by a sprinkler pipe running parallel and ~200mm in front.

The 100x50 trunking at the top is at ceiling level, to the right is an office to which I have no access and the other side of the office is the power/dimmer cupboard. Trunking used to continue to the left [red] but has been cut of almost flush with the office wall to make way for the new hole in the wall for cable basket. Originally [red block] this was to have been some 300mm from the ceiling and office wall and my intention was the new SY lighting cables were to come through the hole and straight up, terminating in glands into the trunking [orange].

However the new hole is less than 100mm from the slab and 40mm from the wall with the top of the basket marginally higher than the bottom of the trunking [hole, basket and trunking shown in black].

It's going to be a PITA but I think the cables will loop round into the end of the trunking OK from the hole.

At the dimmer packs there is a large cut out [maybe 150x30mm from memory] between the vertical 50x50mm trunking and side of pack.

My question based on previous discussions is: what are peoples opinions on the best way to terminate the SY cable. At the moment I'm looking at a pigtail into the earth bar once it's inside the pack but I am struggling to find anywhere to provide any mechanical restraint.

The 2 packs, remainder of the buildings switchgear and trunking take up the height and width of the cupboard.

Access to the 100x50 trunking is restricted by a sprinkler pipe running parallel and ~200mm in front.