- Joined

- 17 Oct 2024

- Messages

- 5

- Reaction score

- 0

- Country

Hi,

New here! Not an expert so looking for pointer(s).

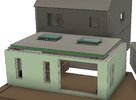

I have the layout as shown and unsure how to best set blocks for minimum cuts etc... but dont want to go moving walls, windows and piers and changing window sizes more than a few cm as theres reasons..

I have attempted, but unclear about when and how much I can lay vertical block ends out of alignment. My builder is now (after quote) giving me lots of 'ooh will cost you with all the cutting!'

I've tried using blocks with single cuts (i.e B1+B2) and carrying on but lintels add a complication too.... as I understand 100mm needed bearing AND MUST be on complete block.... and SE specified 300 overlap for box section/plate above bifold opening... And if full block needed below lintel, i've need to re-jig and first course corner would end up being a half block... OK?

any input (without too much laughing... I was doing it at 3am to meet builder today who didn't turn up) much appreciated.

I'm also assuming first course starting at height of my existing house floor.... at least that's what brickie said...

Mo

New here! Not an expert so looking for pointer(s).

I have the layout as shown and unsure how to best set blocks for minimum cuts etc... but dont want to go moving walls, windows and piers and changing window sizes more than a few cm as theres reasons..

I have attempted, but unclear about when and how much I can lay vertical block ends out of alignment. My builder is now (after quote) giving me lots of 'ooh will cost you with all the cutting!'

I've tried using blocks with single cuts (i.e B1+B2) and carrying on but lintels add a complication too.... as I understand 100mm needed bearing AND MUST be on complete block.... and SE specified 300 overlap for box section/plate above bifold opening... And if full block needed below lintel, i've need to re-jig and first course corner would end up being a half block... OK?

any input (without too much laughing... I was doing it at 3am to meet builder today who didn't turn up) much appreciated.

I'm also assuming first course starting at height of my existing house floor.... at least that's what brickie said...

Mo