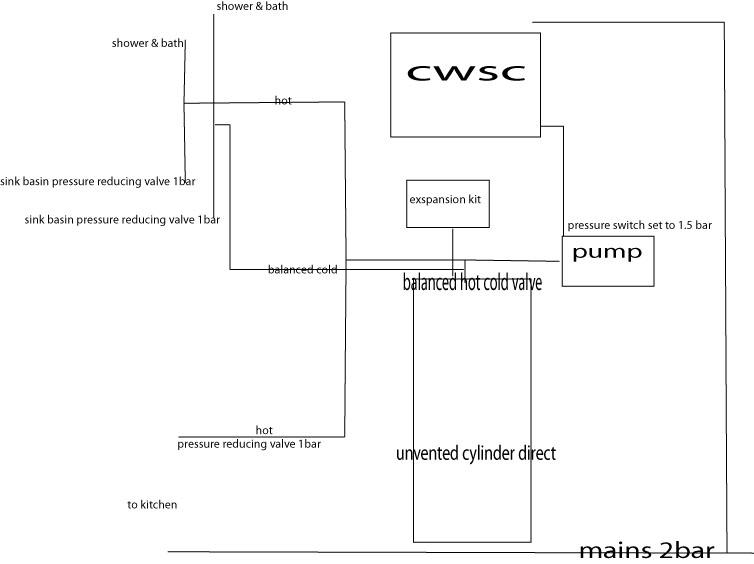

can anyone see a problem with this set up, got a unvented direct cylinder 250l fitted with a balancing valve set at 3bar to supply hot to cylinder and cold to house, was going to set pressure switch to come on when there is a large pressure drop hence fitting reducing valves to basin and sink to stop pump kicking in all the time. Have a pump rated at 60ltm will want priority to new wet room with body jets. Cwsc already in as converting from gravity fed and my central heating is hook up on a completly separate rig. though if i use the two 22mm pipes that come down from loft i.e the old hot and cold t into a 28mm pipe to feed pump and then feed back out of the balancing valve for cold straight back into the old cold supply which is 22mm and convienient in airing cupbard, and the same for the hot.

appreciate any thoughts, new to this site and i'm traing at current for my A.C.S gas course.

image of set up

//www.diynot.com/network/mrrigidtool/albums/

appreciate any thoughts, new to this site and i'm traing at current for my A.C.S gas course.

image of set up

//www.diynot.com/network/mrrigidtool/albums/