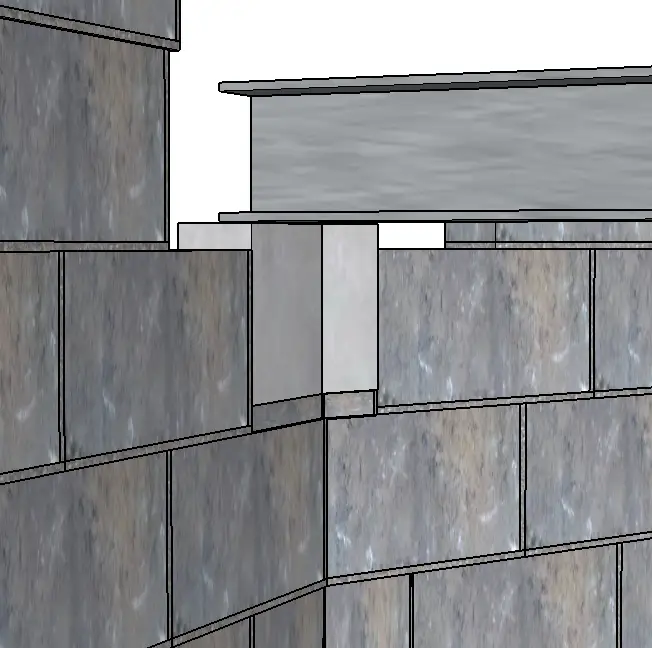

I need to put a 6m steel (203 UC) on a corner that is at a strange angle (approx. 20 degree angle IIRC). As I'm using 7N blocks, the structural engineer said I won't need a padstone. However, as the steel will sit right in the middle of the corner, I'm keen to cast a padstone in situ to avoid putting it directly on the weak point. I've attached a picture of what I'm planning to do (it's not great but I hope you can understand what I'm doing with the steel). I have a few questions:

1. Given that 7N blocks are adequate to support the load, would a standard mix be fine (e.g. C20), or should I get some bags of C40 concrete?

2. Does the padstone need to be symmetric to spread evenly on both walls or is it fine to match the blockwork bond (see picture)?

1. Given that 7N blocks are adequate to support the load, would a standard mix be fine (e.g. C20), or should I get some bags of C40 concrete?

2. Does the padstone need to be symmetric to spread evenly on both walls or is it fine to match the blockwork bond (see picture)?