As a part of my renovation project, I will replace/relocate some radiators and put plastic pipes (current pipework is kinky 8mm copper microbore). While things are relatively easy with upstairs, I am not sure how to approach downstairs. On top of the solid floor, I will have 25mm Celotex insulation under 8mm laminate (see figures below). My plan is to leave a gap between the wall and Celotex and put the CH pipes there, getting rid of ugly pipework dropping from the ceiling. My questions are:

1. 10mm or 15mm pipes? 10 would be easier to handle but I am afraid that the runs will be too long (about 5-6m from the main CH pipes to radiator). I am leaning towards 15mm; downstairs radiators need to work well.

2. How to clip the pipes under the laminate? Is there any standard solution that would fit into the 25mm space between concrete and laminate?

3. Most difficult, how can I connect radiators? I can see three options:

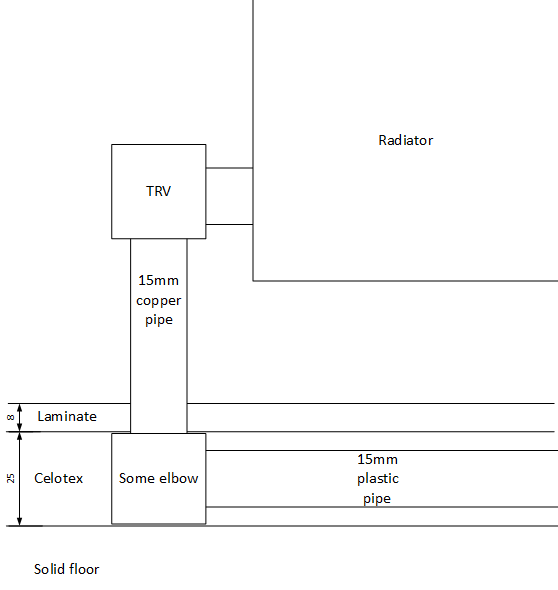

a) Ideally, I would like to have copper pipe between TRV and floor, and then under the laminate an elbow to connect to the horizontal plastic pipe. The main issue here is that, apparently, Speedfit elbows are far too bulky for the 25mm space under the laminate.

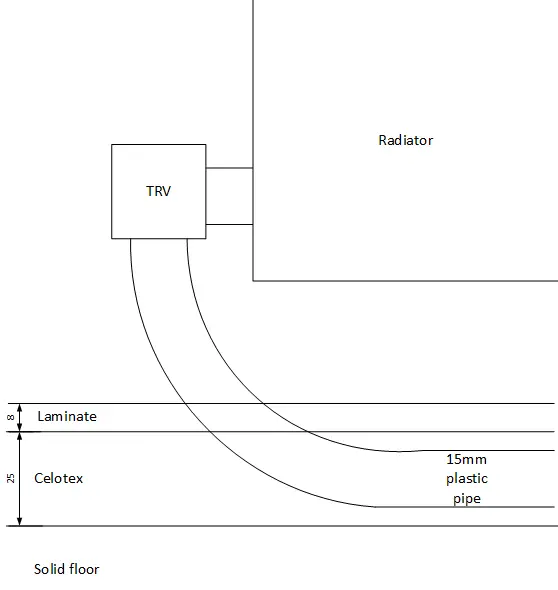

b) Fit the radiator high enough to allow for the bend of the pipe, like in the figure below:

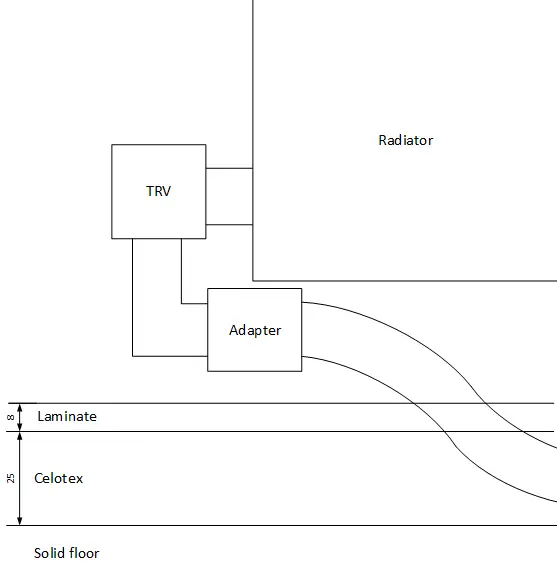

c) Use a short elbow (like Towelrads 15-15mm Pushfit Chrome Elbow) and then run plastic pipe below/behind the radiator like in the figure below. Only one of the feed/return pipes will be hidden this way though.

I understand that some of these problems could be solved by soldering copper but I have neither the tools nor skills.

Any comments will be appreciated!

1. 10mm or 15mm pipes? 10 would be easier to handle but I am afraid that the runs will be too long (about 5-6m from the main CH pipes to radiator). I am leaning towards 15mm; downstairs radiators need to work well.

2. How to clip the pipes under the laminate? Is there any standard solution that would fit into the 25mm space between concrete and laminate?

3. Most difficult, how can I connect radiators? I can see three options:

a) Ideally, I would like to have copper pipe between TRV and floor, and then under the laminate an elbow to connect to the horizontal plastic pipe. The main issue here is that, apparently, Speedfit elbows are far too bulky for the 25mm space under the laminate.

b) Fit the radiator high enough to allow for the bend of the pipe, like in the figure below:

c) Use a short elbow (like Towelrads 15-15mm Pushfit Chrome Elbow) and then run plastic pipe below/behind the radiator like in the figure below. Only one of the feed/return pipes will be hidden this way though.

I understand that some of these problems could be solved by soldering copper but I have neither the tools nor skills.

Any comments will be appreciated!