I don't like your idea. The shuttering will be complex and the killer is to get a good seal where the legs sit on the top of the original stack. A small amount of external leakage would be catastrophic. If you are going to this sophistication, then why not cast a slope on the top (you will need a drip rail anyway) and angled flaunching the the original stack top in the gaps.

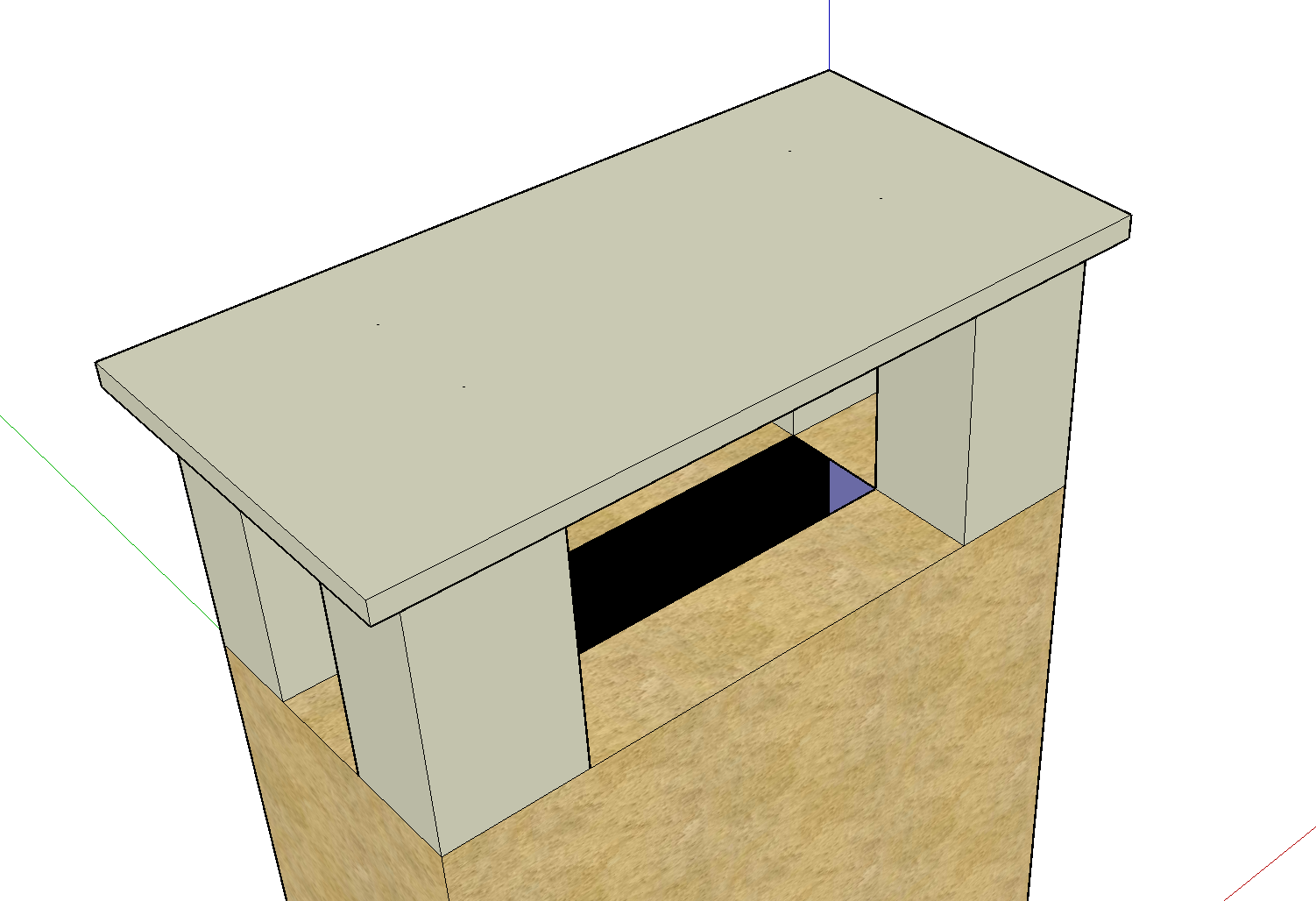

Back to your shuttering. It must work by all the screws holding it together being on the non concrete side of the wood Start of by making a piece that is the underside surface of the top (rectangle with 4 corner cut out). Mount your inside leg shuttering to this by screwing 1" X 1" strips inside the corner gaps (upwards) so your legs butt up to the top of the corner holes. Put a few screws into the external overlaps at the touching corners. Cut more outside corner shuttering which are a bit taller then the inside corner ones so their tops are the same as the top surface of the big bit. Screw all of them together using screws through the edges.

Now you can pour on the big bit and it will flow through the legs, so you better have a good seal against the brickwork. So now you need an overlap for the top, so screw suitable bits of wood (top)level with the top of the big bit around the whole assemblely, so now you have the basic bottom of the top slab.

The next thing to do is the drip rail, this is a 3/8" deep by 1/4" wide groove in the underside of the slab, so you have to machine up a suitable profile and mount it so it sticks up higher the the basic base of the slab. Now you need the actual drip rail, another bit of beading screwed to the outside of the previous bit (1/4"?). You have now reached the outside edge, so now screw on your side shuttering, I think this has to be a 1:3 with steel reinforcing and at least 4" thick to protect the steel.

Now is the time to tart up the inside of your shuttering, The joints that are external should be filled with ordinary filler, I think just using a decent masking tape for joint that are unseen. The external surfaces should be smooth and sealed. The internal surfaces should be well sealed if they are not smooth.

FWIW in 1991 I cast some concrete lintels which were dyed and were identical to the Victorian lintels in the rest of the house. I can't remember for the life of me what I used as a release agent*, but the front surfaces were filled and sanded and has a couple of coats of emulsion. Some of the emulsion stuck to the concrete, but it weathered off after the first winter. The front surface came out polished which lasted at least to 2011. There were some small bubbles but not very visible. So be warned make sure you poke the mix down well around the visible surfaces.

Further thoughts:- I wonder if you mount your shuttering and immediately Put some dryish sharp sand mortar, just in the bottom surface, I wonder if you pour carefully your "pugging" will remain in place long enough to provide a seal. Also when this has been done I think you need some retaining frame to keep the shuttering square to the stack while you pour.

Still don't like the idea !!

Frank

* could have been Mr Sheen !!