It isn’t dangerous for the pressure being high. Hence why I asked

@BlueLoo to confirm why they thought it was. I’m gas safe registered.

Give over.

The PSV's on these systems are set at 3 bar.

You turn the pump on, and you get a pressure rise,

Should the system be satisfied (ie the abv wants to open), you are looking at enough pressure to pop open the psv, spurting hot , boiling water and steam somewhere.

Let's not kid ourselves that the same "Gas safe" chumps who cant follow simple instructions and checklist and who likely built the system in the first place, really did route the psv vents to a truly "safe location".

Aside from personal safety, you also have equipment safety and having these crappy plumbing systems at 3.barg isn't something you want for the integrity of the piping or the equipment in it.

Yes, shark and push fits are rated for much higher, but again, you assume they are fitted diligently.

No need to be "I'm the expert here" on this.

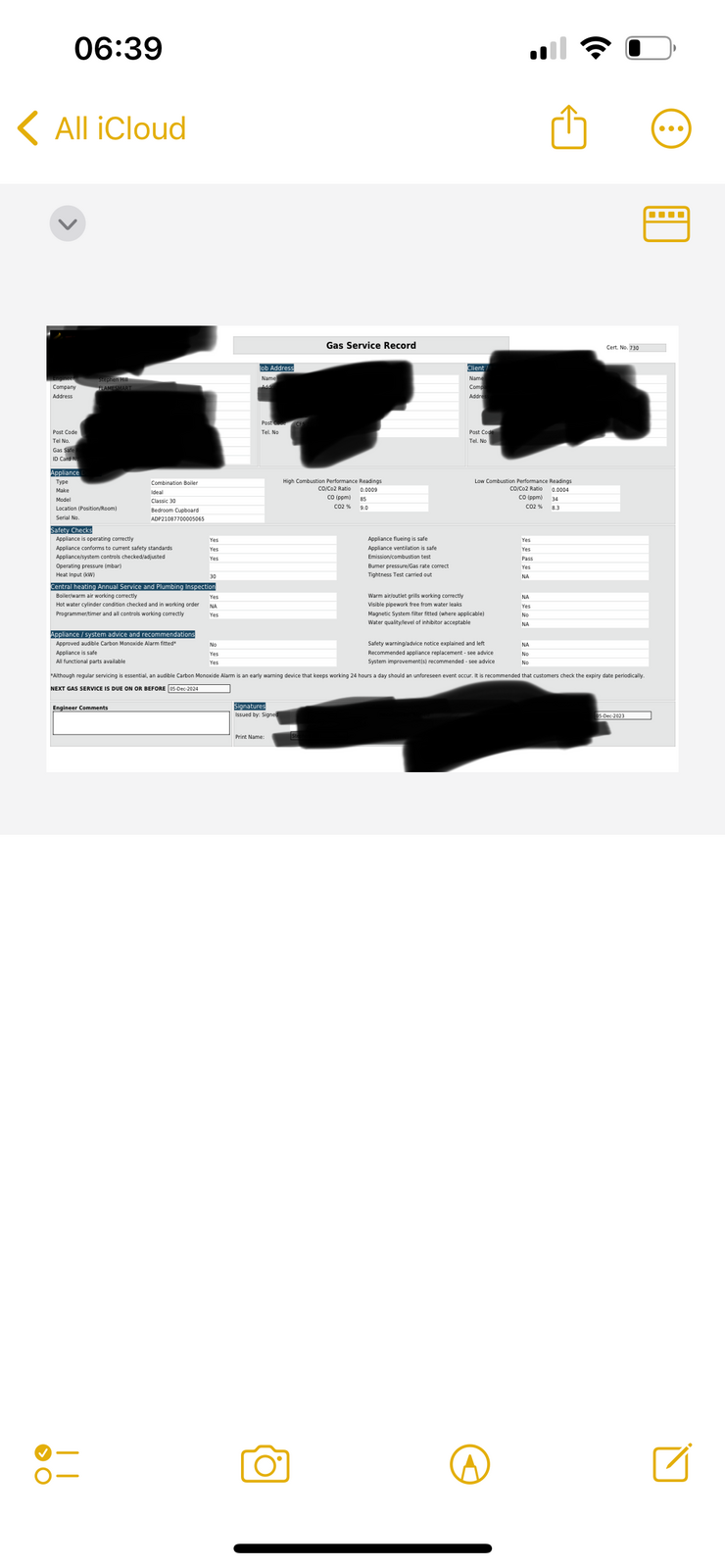

The system has been pressured to open the psv but then not depressured afterwards to the 1.0barg recommended in the iom.

What else did the "Gas safe" idiot forget to do during the service?

We had a thread yesterday where a handful of "Gas safe" engineers couldn't figure out that the "Gas safe" service engineer didn't also read instructions or follow due process and didn't grease the flue seals as he should have.

It is a dangerous over pressure.

It's proof of careless work which is dangerous.

A different, less idiotic "Gas Safe" engineer should recheck the system.

Not rocket science.