I'm now getting further with my utility room project (which was put on hold due to lack of time!)

It started off that I wanted to just redecorate the utility and wc, but as I removed the tiles the plaster board came too, then I decided whilst I was at it I might as well improve it and try and bring it up to current standards.

Part of this was to raise the floor to seperate it from the garage.

I have now built a 2 brick high wall where the stud wall used to be, which I will then build the new stud wall on top of.

This gives me two small areas to fill up to raise the floor.

I'm just hesitating a little as I don't want to get the raising of the floor wrong and I've found it hard to get definite answers on how to do it correctly.

Both rooms are at the back of the garage. The WC was added about 20 years ago as part of an extension (bedroom above the garage and garage widened) - From looking at neighbours originally the WC was where the utility is - so was just moved into the new space to the side.

The WC has a brick outer wall and a concrete block inner wall to 2 sides, my new 2 brick high wall on one side, and a single brick wall between it and the utility.

The utility (which was the WC) has just a single brick wall to the rear, 2 brick wall to one side, my new 2 brick high wall, and the single brick wall to the toilet.

Both have a concrete floor.

From previous research/advice I was going to do the following:

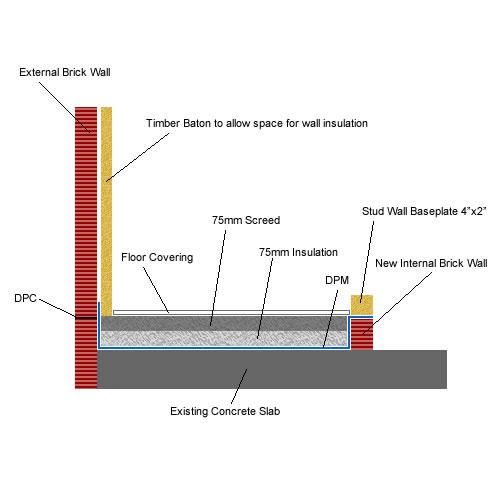

Put DPM down

Put Polystyrene on top

Tape the joints of polystyrene

Concrete over the polystyrene

Firstly does that sound right?

Secondly I have a few little issues/questions:

1. In the utility area the floor isn't fully level. There is a step of about 5mm in the middle - this was covered by the floor covering. I'm guessing this could be enough to cause problems with the Polystyrene. What should I use to level the floor - would sand be OK?

2. Should I just overlap the dpm up the wall a few inches above the floor level?

3. The current single brick wall has a DPC 2 bricks up which just happens to be the same height up that I'm wanting to increase the floor to - will this cause any problems? - This single wall was tiled. All the tiles were stuck on well except the ones below the DPC which just pulled off and smelt a little damp. Obviously this will now be under the floor but will it cause any problems?

4. Someone said it would be better to put the DPM above the polystyrene - which is best?

5. I've seen somewhere a picture where it showed putting edging bits of polystyrene round the edge so the concrete was just in the middle - is this neccessary for my project?

6. Should I use concrete (ballast & cement) or screed on top of the insulation?

7. What thickness of concrete/polystyrene would you recommend to make up the 150mm?

Sorry for all the questions but I must have started this project about a year ago and really need to get it finished off now whilst I have some enthusiasm! It's all stripped out now and I have a few days off next week.

Many thanks

It started off that I wanted to just redecorate the utility and wc, but as I removed the tiles the plaster board came too, then I decided whilst I was at it I might as well improve it and try and bring it up to current standards.

Part of this was to raise the floor to seperate it from the garage.

I have now built a 2 brick high wall where the stud wall used to be, which I will then build the new stud wall on top of.

This gives me two small areas to fill up to raise the floor.

I'm just hesitating a little as I don't want to get the raising of the floor wrong and I've found it hard to get definite answers on how to do it correctly.

Both rooms are at the back of the garage. The WC was added about 20 years ago as part of an extension (bedroom above the garage and garage widened) - From looking at neighbours originally the WC was where the utility is - so was just moved into the new space to the side.

The WC has a brick outer wall and a concrete block inner wall to 2 sides, my new 2 brick high wall on one side, and a single brick wall between it and the utility.

The utility (which was the WC) has just a single brick wall to the rear, 2 brick wall to one side, my new 2 brick high wall, and the single brick wall to the toilet.

Both have a concrete floor.

From previous research/advice I was going to do the following:

Put DPM down

Put Polystyrene on top

Tape the joints of polystyrene

Concrete over the polystyrene

Firstly does that sound right?

Secondly I have a few little issues/questions:

1. In the utility area the floor isn't fully level. There is a step of about 5mm in the middle - this was covered by the floor covering. I'm guessing this could be enough to cause problems with the Polystyrene. What should I use to level the floor - would sand be OK?

2. Should I just overlap the dpm up the wall a few inches above the floor level?

3. The current single brick wall has a DPC 2 bricks up which just happens to be the same height up that I'm wanting to increase the floor to - will this cause any problems? - This single wall was tiled. All the tiles were stuck on well except the ones below the DPC which just pulled off and smelt a little damp. Obviously this will now be under the floor but will it cause any problems?

4. Someone said it would be better to put the DPM above the polystyrene - which is best?

5. I've seen somewhere a picture where it showed putting edging bits of polystyrene round the edge so the concrete was just in the middle - is this neccessary for my project?

6. Should I use concrete (ballast & cement) or screed on top of the insulation?

7. What thickness of concrete/polystyrene would you recommend to make up the 150mm?

Sorry for all the questions but I must have started this project about a year ago and really need to get it finished off now whilst I have some enthusiasm! It's all stripped out now and I have a few days off next week.

Many thanks