Since my CU was fitted in 2006, I've been meaning to tidy it up, because the guy who fitted it made such an abortion of it. I have a week off next week, and plan to tackle this then. Planning is everything, I dont want to leave us without power for too long!

This is what I have right now:

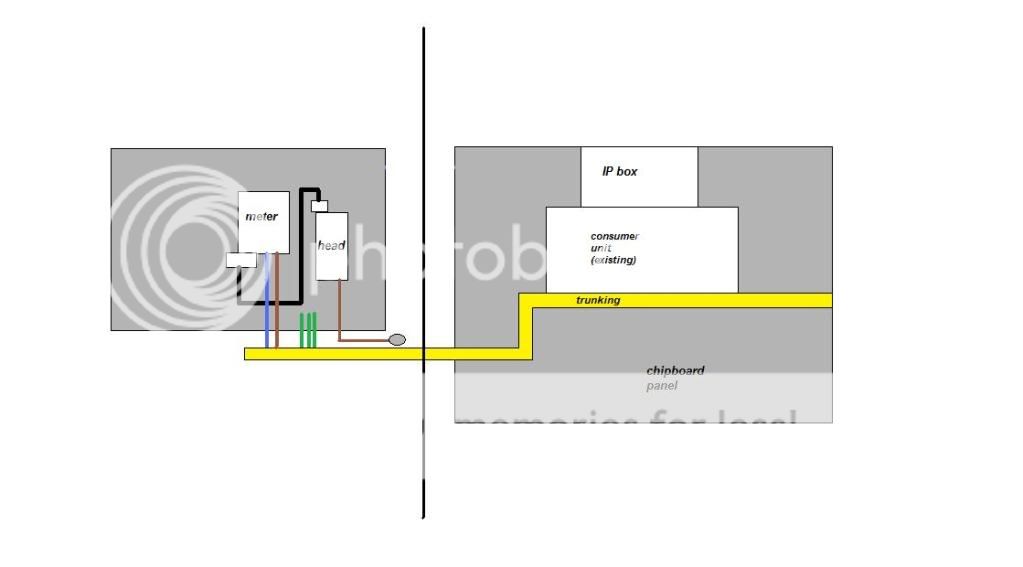

and without all the junk:

Most circuit cables enter the CU from above.

Jobs:

Fit a piece of chipboard, covering all the rough plasterwork on the wall the CU is on.

Renew tails from meter, in one run to the CU.

Fit empty plastic box between the CU and the ceiling.

Refit CU under plastic box.

Extend all circuits via crimps, into the CU.

Use plastic trunking across the bottom of the CU and meter board for the earth bonds and cable exits.

Re-terminate the SWA, which currently just sits inside the bottom of the CU. I have a gland for this (which I left on view for the spark doing the CU change)

Basically, if folded flat, I want to end up with this:

Several queries though.

Do I run the earths up around the CU/box or through them? I know I can use the earth bar in the CU as the MET, would this be a better solution, given the layout?

Can I terminate SWA onto plastic trunking, or will I need another box under the trunking for this? (I have a spare metal box in the shed, I'll probably end up using this anyway, because im guessing that even if allowed, doing it onto plastic will be hard!)

Any tips on using crimps and ratchet crimpers?

Do I need to 17th edition (RCBO) everything, due to extending every circuit?

Anothing thing, during the change, I will need power to drill the wall (I have a cordless but its crap at hammer, be there all day with it). I could also do with power for a light (this is high up under the stairs, no natural light). Would it be wise to temp in a cheap garage CU and double socket for the duration of the work (on ebay, and flog it again after). This way my dad might be able to watch his footy too.

Theres a 10mm cable in the CU for the shower, but the crimper I want only goes up to 6mm. Is there a way? Or do I have to plump for the 10mm crimper?

Are insulated crimps ok as they are, or is it wise to heatshrink them too?

On my shopping list I have:

-butt crimps (20x1.5mm, 20x2.5mm, 10x4-6mm)

-crimper

-240 x 190 x 90mm IP56 Moulded Box

-flat cable glands x10 (for visible cable entries - will just cut a hole in the top of the box against the ceiling for others)

Will buy trunking and board and fixings from B&Q.

I would update the CU to 17th edition, dual RCD etc, but the budget wont stretch that far unfortunately.

Any advice welcome.

Steve.

This is what I have right now:

and without all the junk:

Most circuit cables enter the CU from above.

Jobs:

Fit a piece of chipboard, covering all the rough plasterwork on the wall the CU is on.

Renew tails from meter, in one run to the CU.

Fit empty plastic box between the CU and the ceiling.

Refit CU under plastic box.

Extend all circuits via crimps, into the CU.

Use plastic trunking across the bottom of the CU and meter board for the earth bonds and cable exits.

Re-terminate the SWA, which currently just sits inside the bottom of the CU. I have a gland for this (which I left on view for the spark doing the CU change)

Basically, if folded flat, I want to end up with this:

Several queries though.

Do I run the earths up around the CU/box or through them? I know I can use the earth bar in the CU as the MET, would this be a better solution, given the layout?

Can I terminate SWA onto plastic trunking, or will I need another box under the trunking for this? (I have a spare metal box in the shed, I'll probably end up using this anyway, because im guessing that even if allowed, doing it onto plastic will be hard!)

Any tips on using crimps and ratchet crimpers?

Do I need to 17th edition (RCBO) everything, due to extending every circuit?

Anothing thing, during the change, I will need power to drill the wall (I have a cordless but its crap at hammer, be there all day with it). I could also do with power for a light (this is high up under the stairs, no natural light). Would it be wise to temp in a cheap garage CU and double socket for the duration of the work (on ebay, and flog it again after). This way my dad might be able to watch his footy too.

Theres a 10mm cable in the CU for the shower, but the crimper I want only goes up to 6mm. Is there a way? Or do I have to plump for the 10mm crimper?

Are insulated crimps ok as they are, or is it wise to heatshrink them too?

On my shopping list I have:

-butt crimps (20x1.5mm, 20x2.5mm, 10x4-6mm)

-crimper

-240 x 190 x 90mm IP56 Moulded Box

-flat cable glands x10 (for visible cable entries - will just cut a hole in the top of the box against the ceiling for others)

Will buy trunking and board and fixings from B&Q.

I would update the CU to 17th edition, dual RCD etc, but the budget wont stretch that far unfortunately.

Any advice welcome.

Steve.