The stuff I use is pretty low tech but it works.

The blue tank holds the inversion which I have to swap between 4 and 6" depending on what size pipe I'm working in. A little compressor manages to push it in and open the liner.

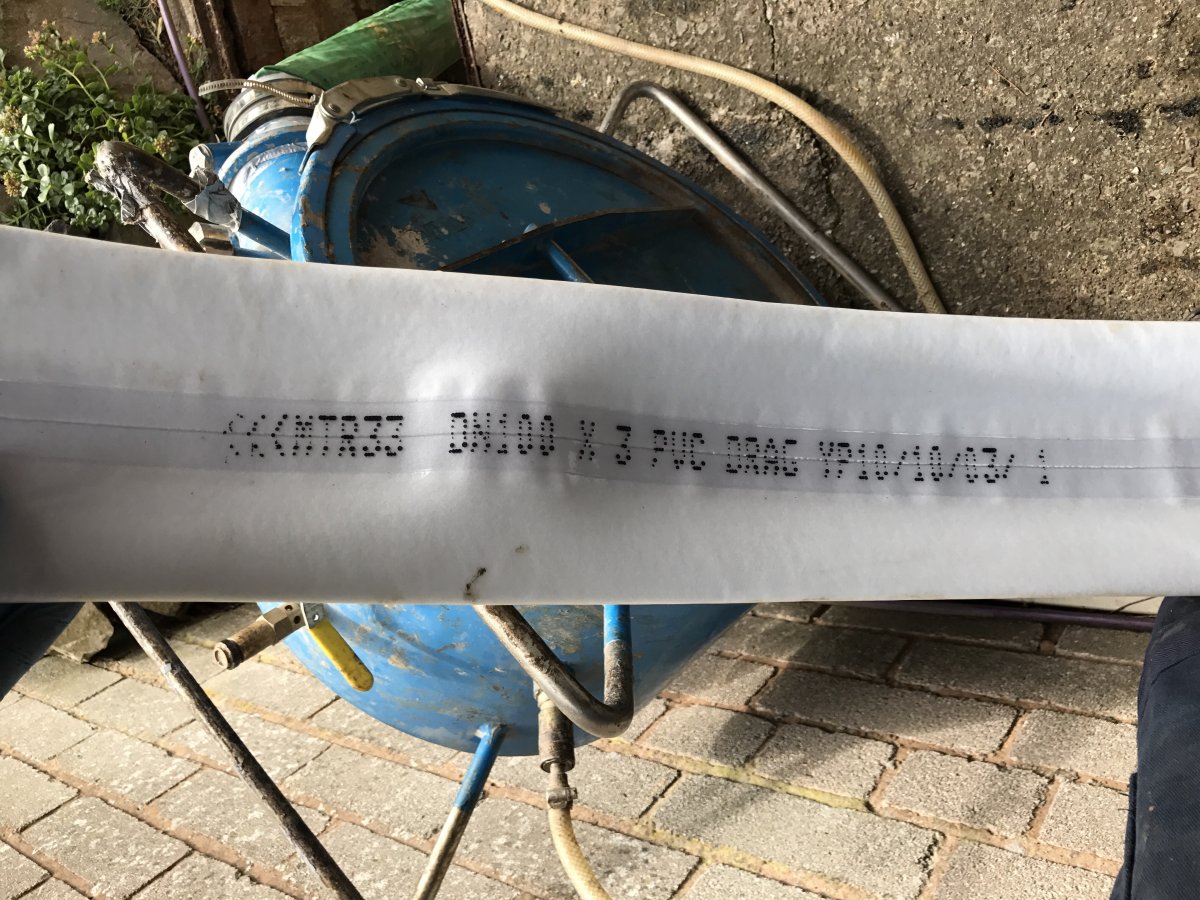

As for the liner, I use Drag on straight runs, Flex on sections with slight bends and Super Flexi on tighter bends. If it was under about 8mtrs I'd push it in with rods, any longer I'd pull it with a rope.

I have to mix a resin with 2 other chemicals to wet the liner, I can adjust the mix to make the liner cure faster or slower depending on its length and how warm the weather is. The roller at the back squeezes out any excess mix and should leave just the right amount in the liner. Longest I've done was 25mtrs and it was a hard pull.

Other than that I just have the patch liner kits which wrap around an inflatable packer and can do just over 1mtr in length.

What do the rest of you use?

I've heard of UV cured liners and also hot water ones but haven't seen or used either.

I had to dig out a 10mtr one because I think whoever installed it had the roller too tight and it was furry once done. I've also seen a massive 6" one that was installed inside out and always wondered what kit they used to do that?

The blue tank holds the inversion which I have to swap between 4 and 6" depending on what size pipe I'm working in. A little compressor manages to push it in and open the liner.

As for the liner, I use Drag on straight runs, Flex on sections with slight bends and Super Flexi on tighter bends. If it was under about 8mtrs I'd push it in with rods, any longer I'd pull it with a rope.

I have to mix a resin with 2 other chemicals to wet the liner, I can adjust the mix to make the liner cure faster or slower depending on its length and how warm the weather is. The roller at the back squeezes out any excess mix and should leave just the right amount in the liner. Longest I've done was 25mtrs and it was a hard pull.

Other than that I just have the patch liner kits which wrap around an inflatable packer and can do just over 1mtr in length.

What do the rest of you use?

I've heard of UV cured liners and also hot water ones but haven't seen or used either.

I had to dig out a 10mtr one because I think whoever installed it had the roller too tight and it was furry once done. I've also seen a massive 6" one that was installed inside out and always wondered what kit they used to do that?