Thanks for all the comments guys

Why are you considering 19th and 20th century options of wood burner and a gas boiler in a new property?

19th century option because I already have a burner and an unlimited supply of wood.

20th century option because its already installed in near brand new condition.

As soon as either go kaput, I will be investing in 21st century tech

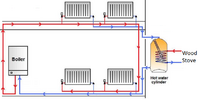

You may have found out that the combi boilers pump will not run for any length of time (bar over run) without the boiler firing/running.

A lot of modern boilers use the return temperature to control modulation so running a preheater may give issues.

Just experimented with my boiler. blasted it to 80c, once the circuit got up to temp I dialled the boiler back down to 30c. The pump continued to run, no gas was being delivered to the combi as the boiler was still at temperature. I watched the boiler for atleast half an hour before retiring the experiment. What I don't know is if the combi was operating the pump at a lower speed. I was just going off sound. The sound of the boiler and the sound of the water gushing through the rads sounded the same.

You'll also need a heatloss rad on the primary pipework from the woodburner.

Any particular reason you want a combi?- if you go for a thermal store rather than a standard cylinder you can have mains pressure hot water via plate hex or large extra coil on the store- both will deliver far more litres/min of hot than a combi.

This is actually a great idea. I was toying with the idea of some sort of thermal mass/heat battery/sand battery as opposed to a hot water tank.

It'll be technically easier to install, safer, less risk of leaks/explosions, and it can act as a heatloss rad that you describe seeing as eg. Sand can be safely heated to hundreds of degrees.

Do i just run a coil of the central heating return pipe through the thermal mass?

You also don't want the return temp to the boiler any warmer than 50odd degrees nominal, otherwise the boiler will not condense and be much less efficient.

Agree, I usually have my boiler temp set to 33c, this is enough to keep my house warm while maximising the condensing effect. However, if I'm heating my system using free wood then condensing efficiency is not a concern. If and when gas is being used (eg. Early mornings before I've loaded the wood burner), the boiler would still be set to 33c so I would still benefit from the condensing effect under these conditions.

I need some advice about a pressure relief valve. There is already one built in to the combi. I would like an additional one somewhere near the wood burner. Where is the best place to have it?

I'm also thinking about another safety mechanism as I don't want to rely on the pressure relief valve.

My underfloor heating is already on smart valves. I can set all the underfloor heating to come on if return temperatures near the boiler approach 80c. Failing that, I can get a smart hot water tap to open, that should absorb enough heat and send it down the drain.

If my safety net is being triggered too often, I could increase the size of the thermal mass.

What do you guys think?

I also need you guys to keep me on the straight and narrow as far as the regs go. I'm not well versed in that area.

Thanks again

CF