Hi All,

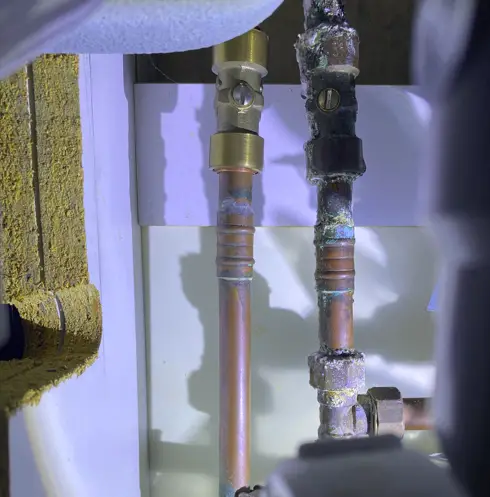

I want to replace this leaking tap

with this new tap

and I'm wondering how to get the old tap out.

I've got a tube spanner to get at the nut but am worried out where to separate the pipes.

Those isolators look like a good place but they look like they're single use press fit?

So you can press them together but you can't pull them apart?

Looking at it, it seems like if I separate the pipes under the isolators, they won't go through the hole for the tap.

I'm not sure how to gain access to separate the pipes above the isolators.

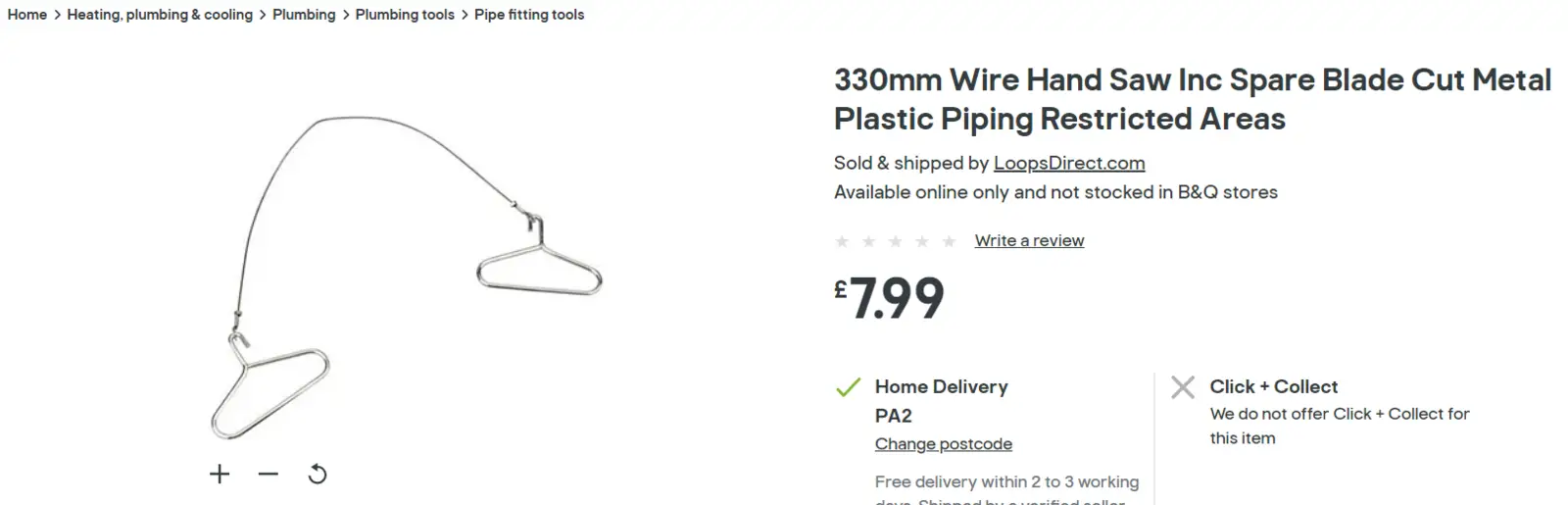

A saw wire ?

Any tips greatly appreciated!

Cheers,

Wilson.

I want to replace this leaking tap

with this new tap

and I'm wondering how to get the old tap out.

I've got a tube spanner to get at the nut but am worried out where to separate the pipes.

Those isolators look like a good place but they look like they're single use press fit?

So you can press them together but you can't pull them apart?

Looking at it, it seems like if I separate the pipes under the isolators, they won't go through the hole for the tap.

I'm not sure how to gain access to separate the pipes above the isolators.

A saw wire ?

Any tips greatly appreciated!

Cheers,

Wilson.