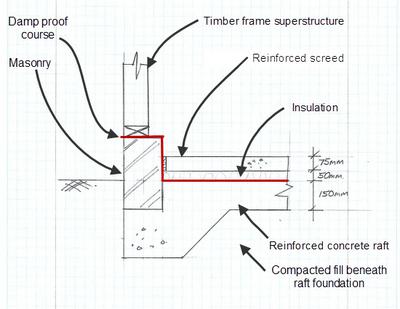

From the NHBC website, this is their guidance for garage foundations:

I plan on using this plus some mesh as my new workshop base. Likely omitting any DPM as I'll be paining a liquid DPM over floor and up to a high DPC due to retaining walls.

My question, is how are you supposed to compact the hardcore under the slab without it spilling into or collapsing the perimeter trenches?

Also, what purpose does it serve, just reduces heave risk?

Cheers,

Fubar.

I plan on using this plus some mesh as my new workshop base. Likely omitting any DPM as I'll be paining a liquid DPM over floor and up to a high DPC due to retaining walls.

My question, is how are you supposed to compact the hardcore under the slab without it spilling into or collapsing the perimeter trenches?

Also, what purpose does it serve, just reduces heave risk?

Cheers,

Fubar.