- Joined

- 11 Sep 2021

- Messages

- 26

- Reaction score

- 0

- Country

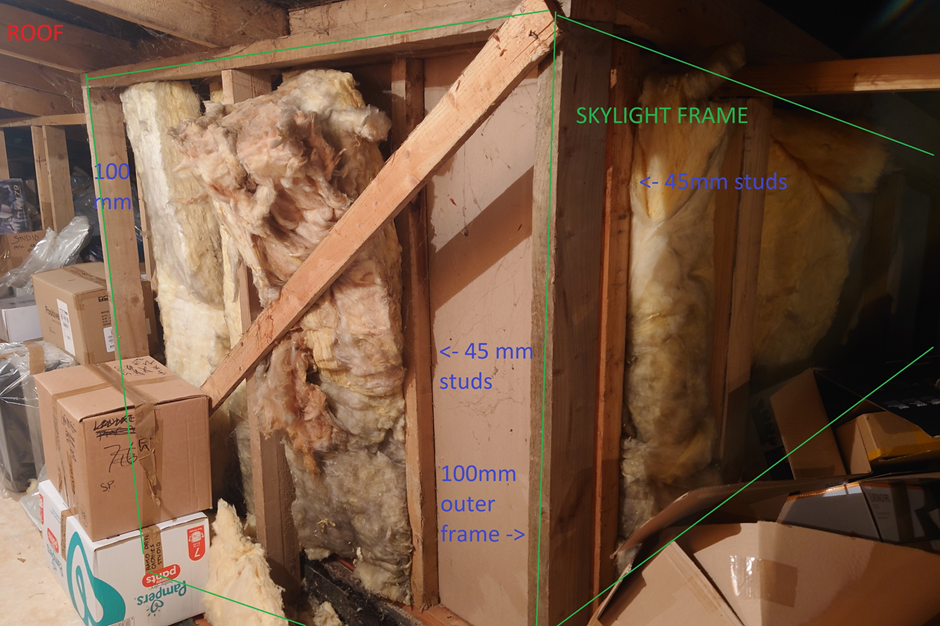

’m looking to insulate a vertical wall onto a cold roof in London. The wall, from inside to out, is paint / presumably plaster / sheet timber (unsure whether OSB / plywood / something else) and a few supporting battens / cold roof.

I guess the key question is whether a VCL is needed on the warm side. And if so, where - on top of the plaster? Or fixed on the other (loft) side (not entirely straightforward, given battens, etc - see below).

In the winter, I guess you’re looking at temperature differentials of perhaps max 23’C inside (typically lower – 18-20’C) and say -4’C outside / in the cold roof.

I’m unsure how best to do this – particularly given:

(i) dew points / risk of interstitial condensation / whether a VCL is needed; and

(ii) the likelihood that we may need access to this wall again, since we’re eventually likely to either replace the large c. 5.8m x 1.6m single sheet polcarbonate skylight that’s at the top of the wall, or secondary glaze it. It’s possible that may require additional structural support. Of course, in an ideal world, we’d do the glazing work first but that may get held up for various reasons, and the heat loss through this wall in the meantime is bad. Even once the glazing’s done, I’m still not sure how best to approach the insulation.

Space isn’t an issue. Seem to be sequence is :

1. Glue downlight covers over LED lights

2. Somehow (?) add a VCL [?] over the all the plywood, studs and downlight covers (so there's a VCL on the warm side).

a) This may not be necessary, given (i) the painted/plastered wood; (ii) if using PIR, the dew point for interstitial condensation would probably fall inside the PIR, which I expect would be fine as there’s not likely to be much moist air in them. Haven’t done a WUFI calculation though.

b) If a VCL is advisable, what should be used? 1000 gauge polythene? Would any of the SuperFoil products be more appropriate?

c) If it is advisable, how;s it best attached?

3. Cover VCL with insulation.

This could be:

(a) 300mm of mineral wool (quick, cheap, easy to work with, breathable), held in place by chickenwire. I have both already. Easy to remove and replace for access. Since mineral wool is breathable, and the wall is plastered and painted, would a VCL be needed on the inside of the timber before the insulation?

(b) As above, but sheep wool insulation (more expensive but no nasty loose fibres in the cold loft space, which is used for storage; good resistance to any moisture).

(c) PIR. Probably in two layers (40mm between the studs, 100 or more over the top). More expensive, harder and more costly to cut and fit, harder to remove and refit once fitted. But perhaps doesn’t require a VCL…? Struggling to see much advantage.

(d) A hybrid. 40mm a or b – or RW3 rockwool sheets – between the studs, the overclad the lot in PIR.

I suspect 3a or 3b is the way forward – just wondering whether the hassle and expense of VCL (2) is sensible. And if a VCL is fitted, does that create the risk of water gathering between the VCL and the wood, which would presumably cause damp/wood rot, etc?

Thoughts greatly appreciated!

Loft side of wall/skylight support

Wall and skylight from inside

I guess the key question is whether a VCL is needed on the warm side. And if so, where - on top of the plaster? Or fixed on the other (loft) side (not entirely straightforward, given battens, etc - see below).

In the winter, I guess you’re looking at temperature differentials of perhaps max 23’C inside (typically lower – 18-20’C) and say -4’C outside / in the cold roof.

I’m unsure how best to do this – particularly given:

(i) dew points / risk of interstitial condensation / whether a VCL is needed; and

(ii) the likelihood that we may need access to this wall again, since we’re eventually likely to either replace the large c. 5.8m x 1.6m single sheet polcarbonate skylight that’s at the top of the wall, or secondary glaze it. It’s possible that may require additional structural support. Of course, in an ideal world, we’d do the glazing work first but that may get held up for various reasons, and the heat loss through this wall in the meantime is bad. Even once the glazing’s done, I’m still not sure how best to approach the insulation.

Space isn’t an issue. Seem to be sequence is :

1. Glue downlight covers over LED lights

2. Somehow (?) add a VCL [?] over the all the plywood, studs and downlight covers (so there's a VCL on the warm side).

a) This may not be necessary, given (i) the painted/plastered wood; (ii) if using PIR, the dew point for interstitial condensation would probably fall inside the PIR, which I expect would be fine as there’s not likely to be much moist air in them. Haven’t done a WUFI calculation though.

b) If a VCL is advisable, what should be used? 1000 gauge polythene? Would any of the SuperFoil products be more appropriate?

c) If it is advisable, how;s it best attached?

3. Cover VCL with insulation.

This could be:

(a) 300mm of mineral wool (quick, cheap, easy to work with, breathable), held in place by chickenwire. I have both already. Easy to remove and replace for access. Since mineral wool is breathable, and the wall is plastered and painted, would a VCL be needed on the inside of the timber before the insulation?

(b) As above, but sheep wool insulation (more expensive but no nasty loose fibres in the cold loft space, which is used for storage; good resistance to any moisture).

(c) PIR. Probably in two layers (40mm between the studs, 100 or more over the top). More expensive, harder and more costly to cut and fit, harder to remove and refit once fitted. But perhaps doesn’t require a VCL…? Struggling to see much advantage.

(d) A hybrid. 40mm a or b – or RW3 rockwool sheets – between the studs, the overclad the lot in PIR.

I suspect 3a or 3b is the way forward – just wondering whether the hassle and expense of VCL (2) is sensible. And if a VCL is fitted, does that create the risk of water gathering between the VCL and the wood, which would presumably cause damp/wood rot, etc?

Thoughts greatly appreciated!

Loft side of wall/skylight support

Wall and skylight from inside