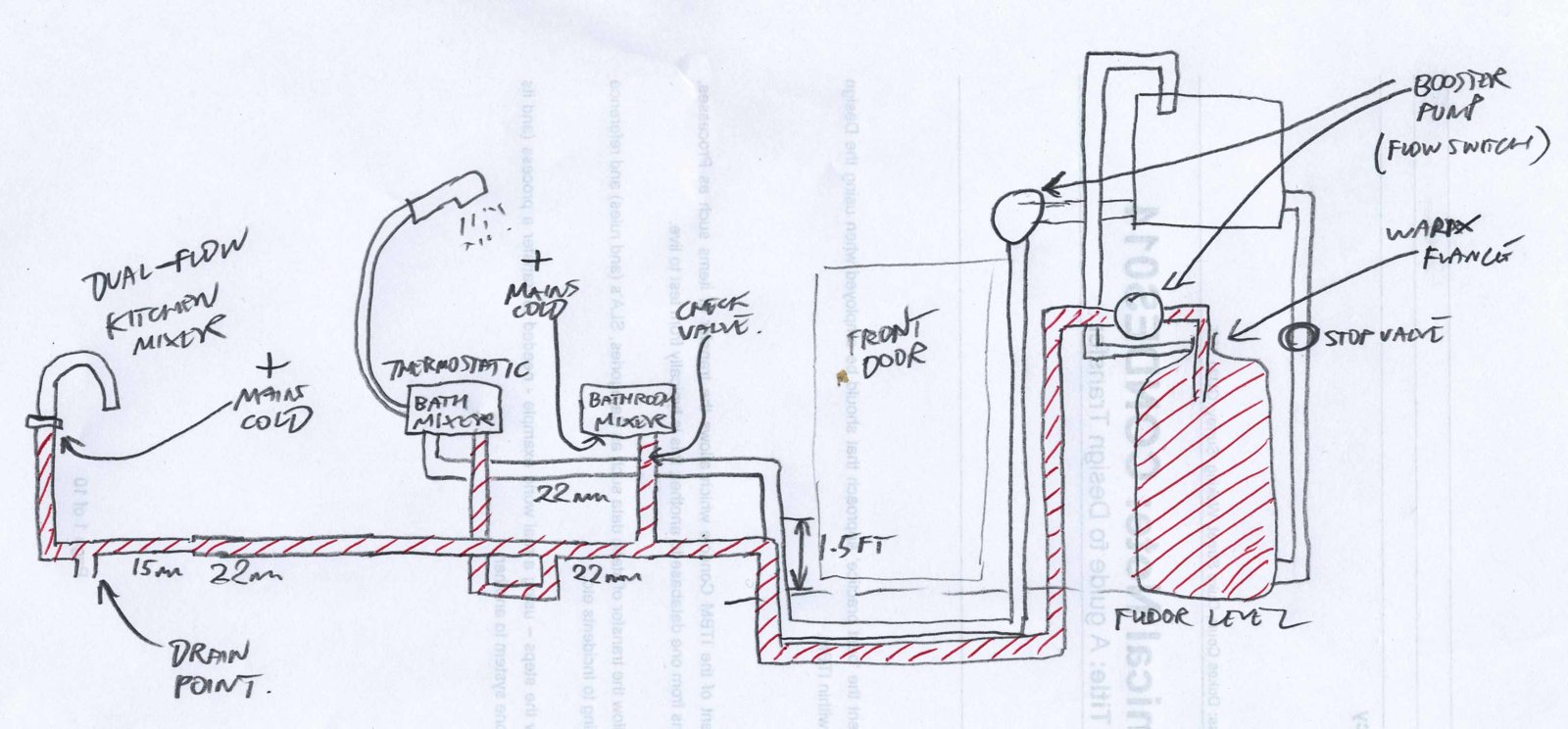

Situation is a flat with roughly the following configuration. The hot water flow in all the flats is poor due to relatively low head of water - even with the old style of taps. The pipework also has to dip under the floor to get across the hall where the front door is.

So, the hot water is boosted at the tank with a Grundfoss Home Booster pump which has a flow switch (and the low pressure cold to the thermostatic bath mixer is also boosted with the same type of pump as it has a shower attachment on it).

This setup works really well and has allowed modern taps to be fitted. The only tweak needed was to fit a high flow aerator to the bathroom mixer tap as the flow with the standard one was too low to encourage the flow switch on the booster pump to trip in.

The problem is this setup occasionally seems to air lock and I can't understand why given that nothing is above the level of the cold water tank and its a relatively simple pipe run. We're talking maybe once every 3-6 months (AND after every occasion where the hot water stop valve is turned off at the input to the tank and the pipes to the taps drained down for any reason).

The symptoms of the intermittent air lock are a gradual reduction in flow from the taps and the pump not kicking in. If you notice and catch it early enough, simply turning on all the taps can sometimes sort it - where the pump then kicks in and presumably helps shift the lock judging by all the gurgling noises.

But if that isn't done, the water flow will eventually slow to a trickle and it doesn't matter what you do with the taps at that point - it won't shift without help. Even switching the booster pump to manual operation which I would have expected would blast any air lock through, doesn't work if it gets to this point.

So, what I usually do is draw off a bit of water at the drain point under the kitchen tap and after a few seconds, the pump will kick in and the problem will sort itself out with loads of gurgling. With it being a dual flow mixer in the kitchen, I would have expected opening that tap up would have had the same effect - but it clearly doesn't. The only thing I haven't tried is taking the aerator/filter off the kitchen mixer when this situation occurs to see if that sorts it.

Any ideas? Thanks.

So, the hot water is boosted at the tank with a Grundfoss Home Booster pump which has a flow switch (and the low pressure cold to the thermostatic bath mixer is also boosted with the same type of pump as it has a shower attachment on it).

This setup works really well and has allowed modern taps to be fitted. The only tweak needed was to fit a high flow aerator to the bathroom mixer tap as the flow with the standard one was too low to encourage the flow switch on the booster pump to trip in.

The problem is this setup occasionally seems to air lock and I can't understand why given that nothing is above the level of the cold water tank and its a relatively simple pipe run. We're talking maybe once every 3-6 months (AND after every occasion where the hot water stop valve is turned off at the input to the tank and the pipes to the taps drained down for any reason).

The symptoms of the intermittent air lock are a gradual reduction in flow from the taps and the pump not kicking in. If you notice and catch it early enough, simply turning on all the taps can sometimes sort it - where the pump then kicks in and presumably helps shift the lock judging by all the gurgling noises.

But if that isn't done, the water flow will eventually slow to a trickle and it doesn't matter what you do with the taps at that point - it won't shift without help. Even switching the booster pump to manual operation which I would have expected would blast any air lock through, doesn't work if it gets to this point.

So, what I usually do is draw off a bit of water at the drain point under the kitchen tap and after a few seconds, the pump will kick in and the problem will sort itself out with loads of gurgling. With it being a dual flow mixer in the kitchen, I would have expected opening that tap up would have had the same effect - but it clearly doesn't. The only thing I haven't tried is taking the aerator/filter off the kitchen mixer when this situation occurs to see if that sorts it.

Any ideas? Thanks.

Attachments

Last edited: