GoSystem Auto Start Blow Torch

Quick to warm up and easy to use - this GoSystem blow torch is perfect for general DIY work along with paint stripping, plumbing and intermediate soldering jobs.Supplied with a 170g gas cartridge, the torch has a maximum operating temperature of 1600°C and features an auto-start Piezo ignition...

As above, I'm looking to replumb a cloakroom, and i have no experience with soldering. I was going to use compression, but the joints will be boxed in and tiled, so prefer to solder, and thinking its a good skill to learn anyway?

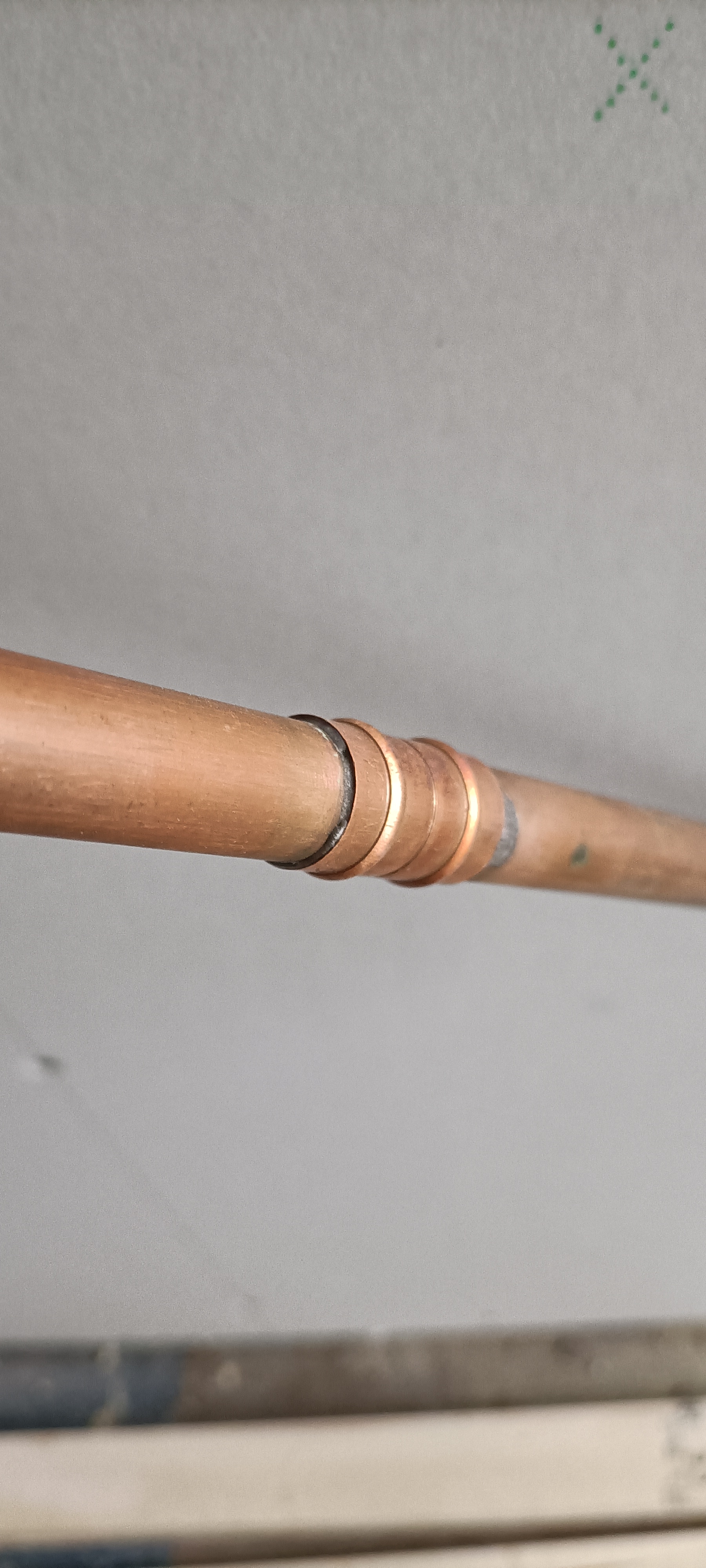

I have a few bits of scrap copper to test/practice with some solder ring fittings, and i already have the torch as someone gave it to me. Will it be OK for this job? I am hoping i can cut/mark the pipes and solder them together on a bench, so shouldn't be needing to solder upside down or in awkward spaces?

Thanks