I have had to lift some 5 finger parquet floor to allow underfloor access (Gas pipe and pesky sleeper walls with no access holes...) and I guess I might need to lift it again in the future.

To get it up without damaging it we had to start at the edge and lift quite a bit -in the end we just took it all up.

It isn't a massive area - about 1.5 by 2m. I'm currently cleaning the blocks to relay (fun job!) and the floor boards wi ll need cleaning too. Also not walking on it for 24hrs will severely restrict access to the rest of the house - I don't think it is possible.

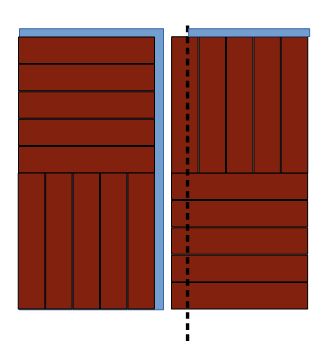

So I was wondering if I could relay it as planks or tiles on hardboard - like a floating floor. I would make them over lap (kind of like a tongue and groove) and leave an expansion gap/lifting edge under the skirtings. It wouldn't be easy to lift in the future but would be easier than it is currently being (no scraping at least!). I was thinking about making some kind of hatch - I still might. But the floating floor/plank idea would mean I could arrange the blocks and allow to set anywhere - so wouldn't have the walking on problem.

I've attached a couple of images to give an idea of what I mean (blue is hardboard) I guess I could put some kind of laminate floor underlay underneath too -if that would help.

So does it sound possible? Has anyone done anything like it before? What are the problems with doing it?

Thanks!

To get it up without damaging it we had to start at the edge and lift quite a bit -in the end we just took it all up.

It isn't a massive area - about 1.5 by 2m. I'm currently cleaning the blocks to relay (fun job!) and the floor boards wi ll need cleaning too. Also not walking on it for 24hrs will severely restrict access to the rest of the house - I don't think it is possible.

So I was wondering if I could relay it as planks or tiles on hardboard - like a floating floor. I would make them over lap (kind of like a tongue and groove) and leave an expansion gap/lifting edge under the skirtings. It wouldn't be easy to lift in the future but would be easier than it is currently being (no scraping at least!). I was thinking about making some kind of hatch - I still might. But the floating floor/plank idea would mean I could arrange the blocks and allow to set anywhere - so wouldn't have the walking on problem.

I've attached a couple of images to give an idea of what I mean (blue is hardboard) I guess I could put some kind of laminate floor underlay underneath too -if that would help.

So does it sound possible? Has anyone done anything like it before? What are the problems with doing it?

Thanks!