Evening all,

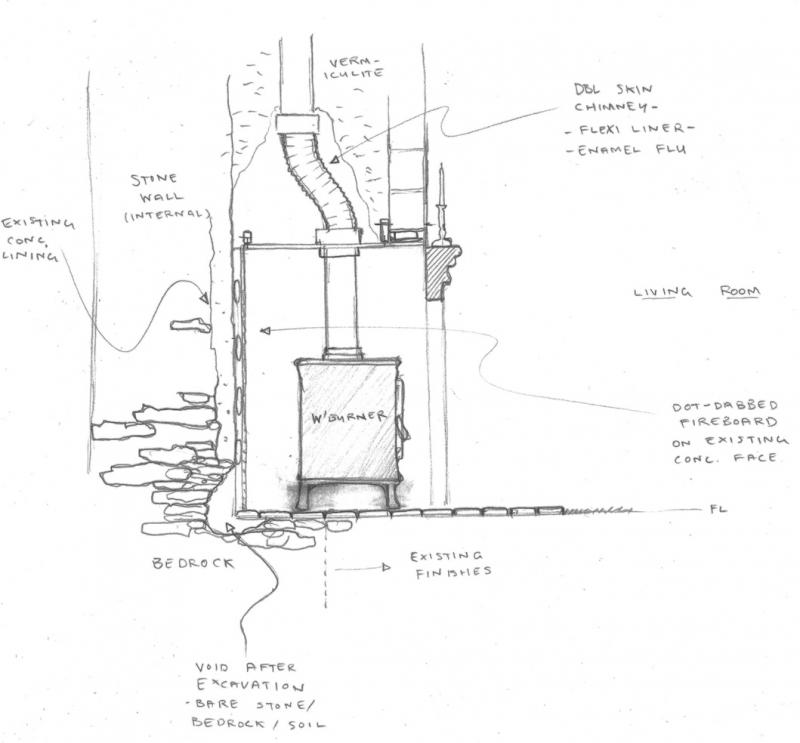

I am in the process of reinstating an old fireplace in order to take a woodburner. The recess of the old fireplace is already concrete lined and exists in an old stone wall, as per cross section diagram. Unfortunately, during the excavations to get to the fireplace, we had to created an opening in the lining, revealing the base of the stone wall and some bedrock (see pics) and I'm wondering whether this will be an issue.

After doing my homework, I figured a dot-dabbed, fire resistant non-gypsum based board would be good for the lining but I'm at a loss as to what to do with the revealed stone, especially when considering damp issues?

An additional minor issue: The base of the existing chimney lining terminates half an arms length above the register plate and is packed with vermiculite. It should be easy enough to attach an adapter to a flexi liner in such confined space, right? If it needs a screw it'll take some contortionist driver work.

Feedback would be much appreciated. Thanks for your time.

Alan

Cross Section for your amusement

Fireplace as it stands (n.b. decommissioned gas pipes enter through the centre-bottom, packed in yellow sand, visible)

Detail of the revealed bedrock

I am in the process of reinstating an old fireplace in order to take a woodburner. The recess of the old fireplace is already concrete lined and exists in an old stone wall, as per cross section diagram. Unfortunately, during the excavations to get to the fireplace, we had to created an opening in the lining, revealing the base of the stone wall and some bedrock (see pics) and I'm wondering whether this will be an issue.

After doing my homework, I figured a dot-dabbed, fire resistant non-gypsum based board would be good for the lining but I'm at a loss as to what to do with the revealed stone, especially when considering damp issues?

An additional minor issue: The base of the existing chimney lining terminates half an arms length above the register plate and is packed with vermiculite. It should be easy enough to attach an adapter to a flexi liner in such confined space, right? If it needs a screw it'll take some contortionist driver work.

Feedback would be much appreciated. Thanks for your time.

Alan

Cross Section for your amusement

Fireplace as it stands (n.b. decommissioned gas pipes enter through the centre-bottom, packed in yellow sand, visible)

Detail of the revealed bedrock