Hi everyone,

I've been experiencing some constant air bubbling noise on the top floor of our house. I've done some investigating and I think I know what's happening but I'm not expert so I figured it would be best to check with people in the know.

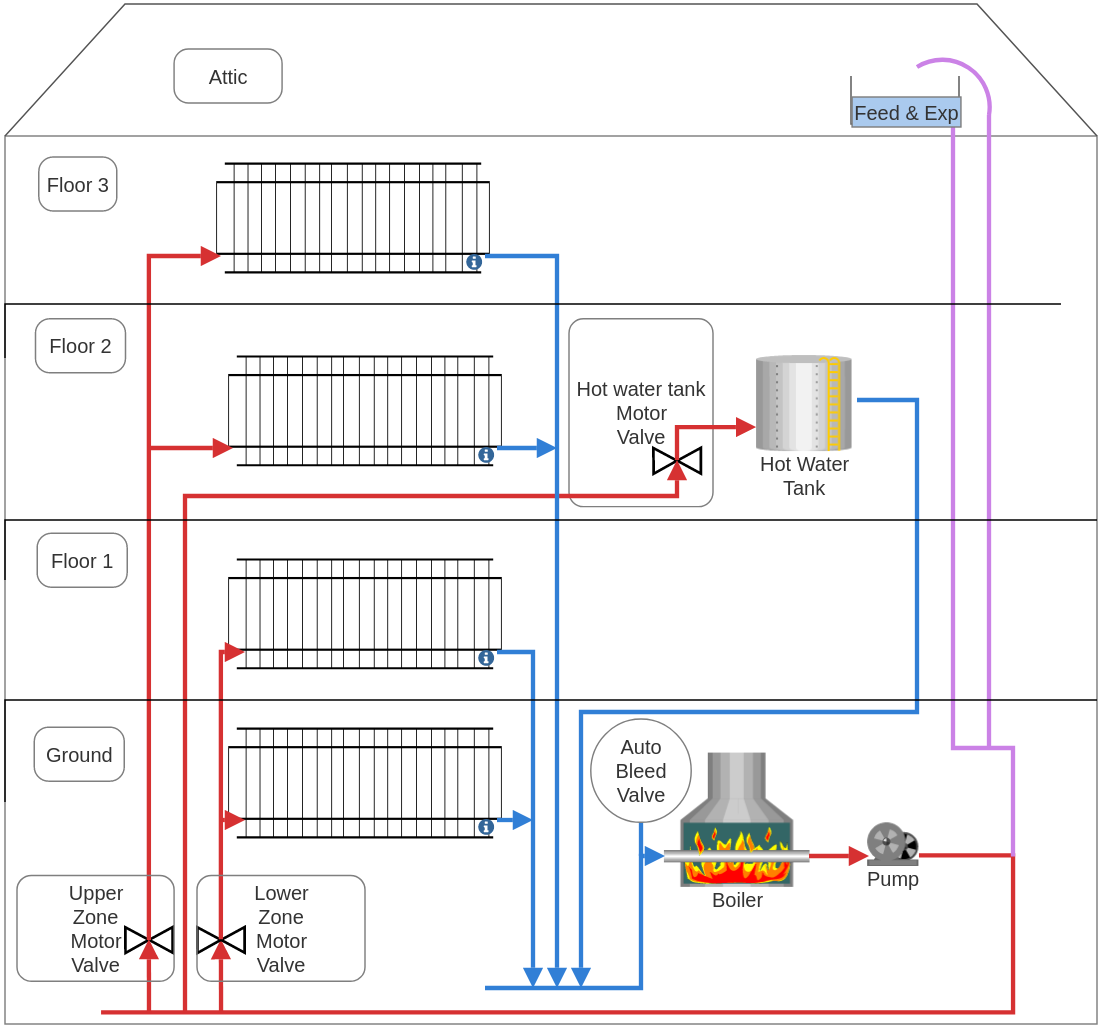

I've tried to map out the system so here goes:

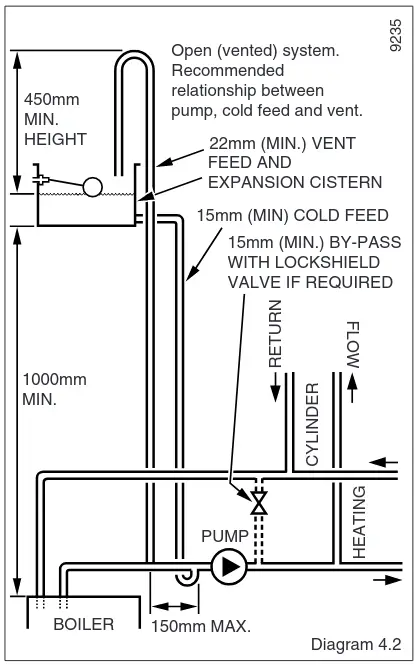

The boiler is a Gloworm 24hxi and here's what the manual says about the water setup:

You'll notice that in my house:

A) The pump is before the feed/exp tank rather than after!!! (other posters have reported bubbling issues with that kind of pump position)

B) There is no auto by-pass valve (even though the 3 zones can all close at the same time)

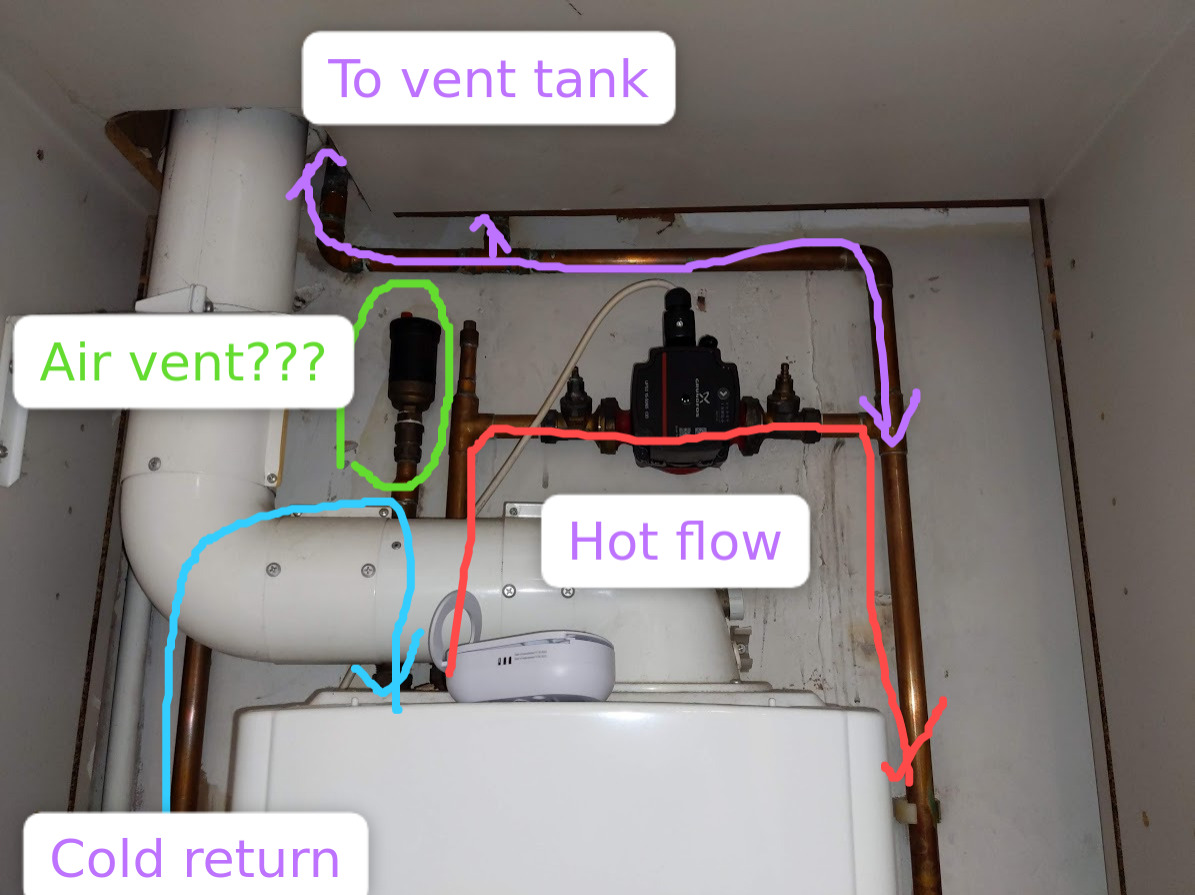

C) There's an auto bleed valve just before the boiler which isn't in the manual

As a result of A & B, when the last zone decides to shut down and the pump overrun keeps the pump going for another 5 minutes it creates a massively negative pressure in the system as it's pulling on the return and all the flows are closed. Indeed, if I open a bleeding valve on one of the top floor radiators, air rushes in until the pump shuts off at which point water rushes back up. Hell, I assume if the pump is powerful enough, it might even manage to pull some air from the bleed valve that's next to the boiler?

To mitigate the bubbling noise in the winter, I bleed top floor radiators twice a day and I've set the boiler pump to minimum power and the boiler temp reasonably low to reduce the frequency and severity of these low pressure events.

I guess there could be other reasons for air bubbles as well but I suspect they will be hard to identify without fixing this one.

So here are 4 actions I can envision:

1) Rearrange the expansion pipe, feed pipe and pump to be in that order!

2) Add the required auto by-pass valve (maybe the right place for it is around the hot water tank motorized valve as it's hard to imagine a better heat sink than the hot water tank no?)

3) A hack: try to see if the Honeywell hot water tank motorized valve can be locked open, without somehow affecting the demand signal of the hot water tank thermostat to the boiler?

4) Remove that auto air bleed valve next to the boiler

I think any one of 1, 2 or 3 should prevent the negative pressure periods during pump overrun, but the best solution is probably 1 + 2. Anyone disagrees?

Is 4 worth doing? Is there a reason for that bleed valve being there?

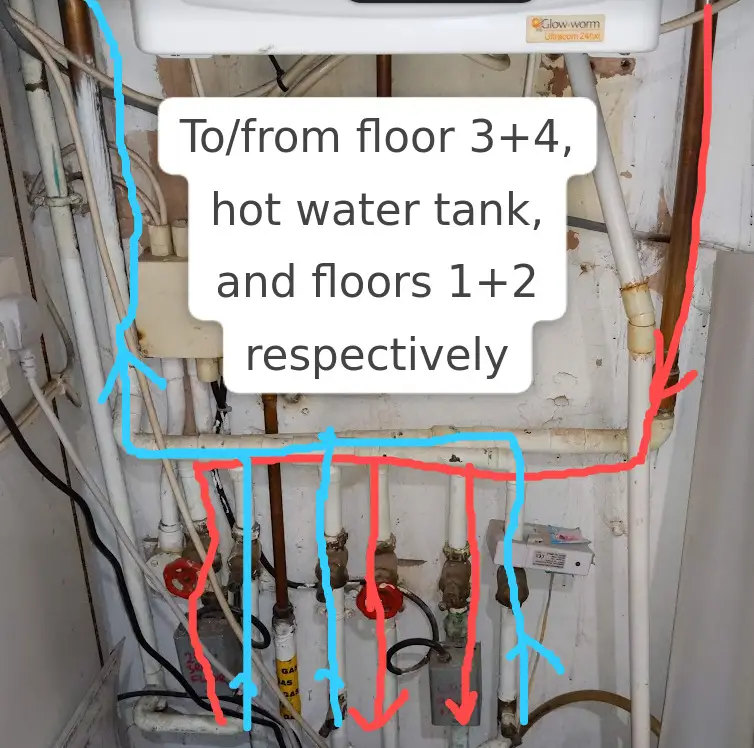

Finally I'll throw in some pictures of the piping around the boiler in case anyone notices something I didn't:

Thank you in advance for your thoughts!

I've been experiencing some constant air bubbling noise on the top floor of our house. I've done some investigating and I think I know what's happening but I'm not expert so I figured it would be best to check with people in the know.

I've tried to map out the system so here goes:

The boiler is a Gloworm 24hxi and here's what the manual says about the water setup:

You'll notice that in my house:

A) The pump is before the feed/exp tank rather than after!!! (other posters have reported bubbling issues with that kind of pump position)

B) There is no auto by-pass valve (even though the 3 zones can all close at the same time)

C) There's an auto bleed valve just before the boiler which isn't in the manual

As a result of A & B, when the last zone decides to shut down and the pump overrun keeps the pump going for another 5 minutes it creates a massively negative pressure in the system as it's pulling on the return and all the flows are closed. Indeed, if I open a bleeding valve on one of the top floor radiators, air rushes in until the pump shuts off at which point water rushes back up. Hell, I assume if the pump is powerful enough, it might even manage to pull some air from the bleed valve that's next to the boiler?

To mitigate the bubbling noise in the winter, I bleed top floor radiators twice a day and I've set the boiler pump to minimum power and the boiler temp reasonably low to reduce the frequency and severity of these low pressure events.

I guess there could be other reasons for air bubbles as well but I suspect they will be hard to identify without fixing this one.

So here are 4 actions I can envision:

1) Rearrange the expansion pipe, feed pipe and pump to be in that order!

2) Add the required auto by-pass valve (maybe the right place for it is around the hot water tank motorized valve as it's hard to imagine a better heat sink than the hot water tank no?)

3) A hack: try to see if the Honeywell hot water tank motorized valve can be locked open, without somehow affecting the demand signal of the hot water tank thermostat to the boiler?

4) Remove that auto air bleed valve next to the boiler

I think any one of 1, 2 or 3 should prevent the negative pressure periods during pump overrun, but the best solution is probably 1 + 2. Anyone disagrees?

Is 4 worth doing? Is there a reason for that bleed valve being there?

Finally I'll throw in some pictures of the piping around the boiler in case anyone notices something I didn't:

Thank you in advance for your thoughts!