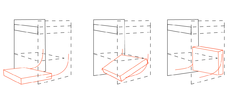

I have made a high sleeper bed, with a desk beneath. To add to the utility of this unit I want to install a fold-out bed, that effectively stands behind the desk when not in use, and extends beneath the desk when required. That is to say that the foldaway bed has the foot postion on the left, the head position on the right and the width stands upright against a wall.

I can conceptualise the way to make this work, with a curved roller guide at each end of the bed frame, so that when pushed from the "open" side the guide raises the bed on the "closed" side until is is vertical (ie parallel to the wall), but I can’t figure out how to engineer the thing. I have seen custom rollers and guides online, but these look like they are designed for food production conveyor belts (or similar) in horizontal rather than vertical configurations.

Any suggestions?

I can conceptualise the way to make this work, with a curved roller guide at each end of the bed frame, so that when pushed from the "open" side the guide raises the bed on the "closed" side until is is vertical (ie parallel to the wall), but I can’t figure out how to engineer the thing. I have seen custom rollers and guides online, but these look like they are designed for food production conveyor belts (or similar) in horizontal rather than vertical configurations.

Any suggestions?