Hey all,

So I am building my first shed, and I am designing the flooring / joists and how they will fit together. From what I kind find on the market for joists... I only see 2.4m, 3m, 4.2m, 4.8m etc cuts. For this shed, I was thinking of using:

Pressure Treated Softwood Joist Timber - 47 x 150mm x 4.8m / 3.0m C24

I was thinking of making the shed 3m x 5m.

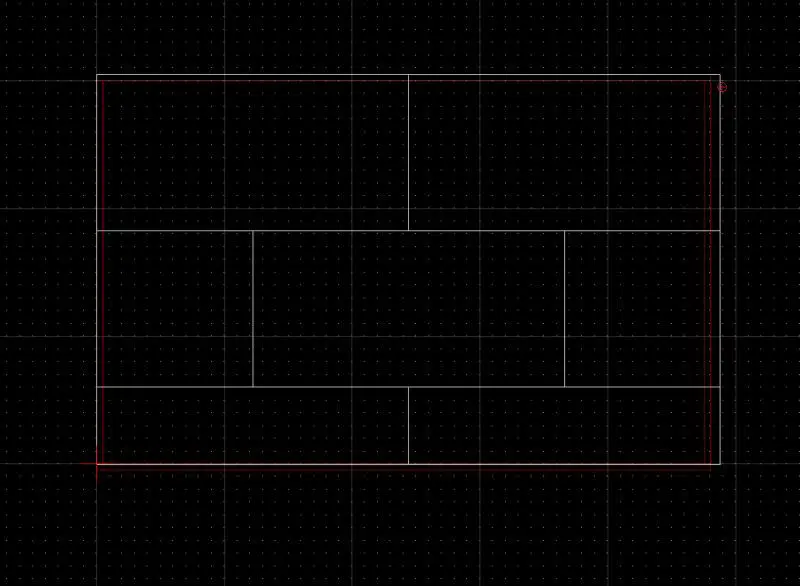

Thats fine so far... so then I look at Marine Plywood for the flooring. It only comes in 1220x2440 cuts. OK, so I draw how the Plywood will fit on various configurations of the joists.. and its SLIGHLTY off by a tiny fraction in each way I can think of.

I have two options.. cut the timber or buy an extra plywood.

If I cut the timber, I would have to "treat" the edges again, how hard is that? Is it easier to just get an extra plywood and use the extra to make a desk or shelves or something?

Thanks

So I am building my first shed, and I am designing the flooring / joists and how they will fit together. From what I kind find on the market for joists... I only see 2.4m, 3m, 4.2m, 4.8m etc cuts. For this shed, I was thinking of using:

Pressure Treated Softwood Joist Timber - 47 x 150mm x 4.8m / 3.0m C24

I was thinking of making the shed 3m x 5m.

Thats fine so far... so then I look at Marine Plywood for the flooring. It only comes in 1220x2440 cuts. OK, so I draw how the Plywood will fit on various configurations of the joists.. and its SLIGHLTY off by a tiny fraction in each way I can think of.

I have two options.. cut the timber or buy an extra plywood.

If I cut the timber, I would have to "treat" the edges again, how hard is that? Is it easier to just get an extra plywood and use the extra to make a desk or shelves or something?

Thanks