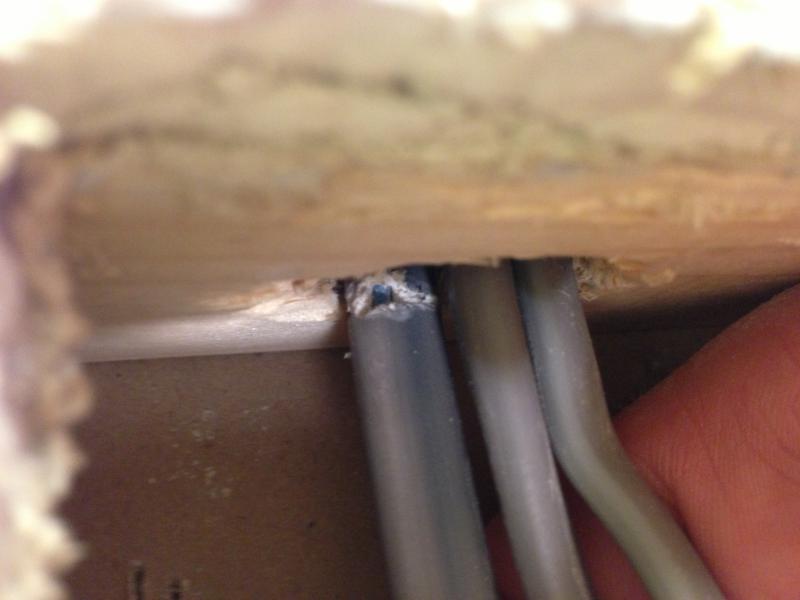

Over the weekend I was moving a telephone socket, while I doing this I noticed a small spilt in the outer sheath of a nearby the twin and earth cable around the area where the cable was pulled though the timber (in a stud wall), I can see the blue neutral cable within the twin and core, the blue sheath appears not to be damaged. Is this something that I should be considered about, is this against the regs?.

Regards

BBinterS

Regards

BBinterS