I removed some old 27mm T&G flooring. To remove bounce, I then double-sistered and leveled the 75mm floor joists with 2x 45mm sisters. Now I'm thinking about how to install the new 20mm engineered floorboards.

I have 7mm spare. The final height of the floor cannot be raised.

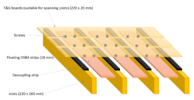

Ideally, I'd make a floating floor, but could screw them directly to joists if not possible.

How crazy is my idea in the attached image?

I have 7mm spare. The final height of the floor cannot be raised.

Ideally, I'd make a floating floor, but could screw them directly to joists if not possible.

How crazy is my idea in the attached image?