- Joined

- 12 Apr 2023

- Messages

- 2

- Reaction score

- 0

- Country

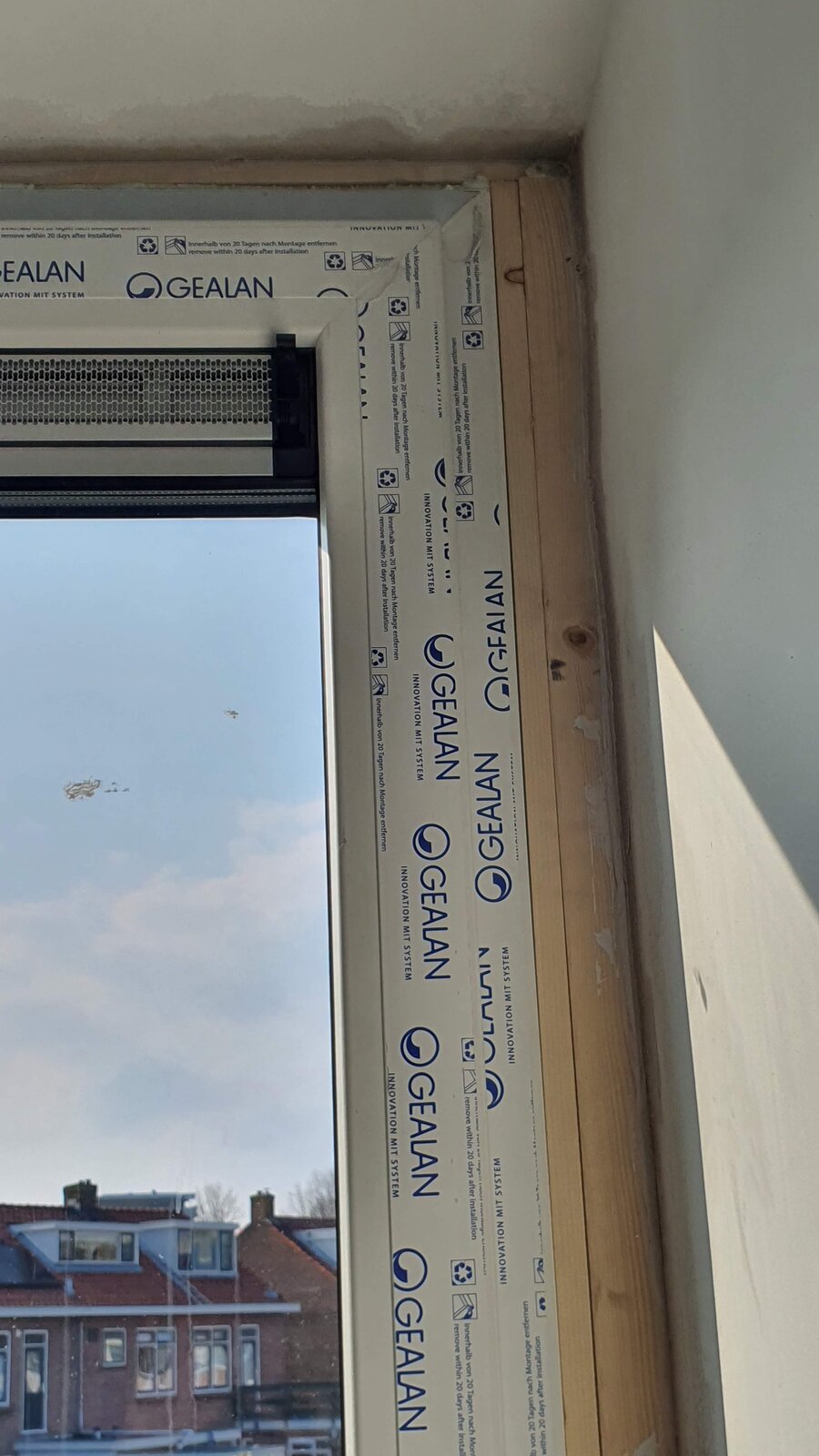

I just got new uPVC window installed on a cavity wall of a 1969 house.

I try to put the picture step by step how the worker fitted my window.

They removed the window [with such a mess], and I put picture from the starting of the fitting.

There are leveling wood (orange) in between cavity wall, but is it not fixed to the wall.

On the bottom and top, there are already wood exist.

The installer put wood piece and foam to fix the orange wood on the side.

And put a piece of wood to make it level. (see the top)

It is the same at the bottom, then he put lead strip over it at the bottom. The lead strip is not go up to the side.

The top and bottom are perfect level at this moment. [but not later]

On the other side, he put some wood to level them.

Then the window are put into it, without any sealant on any side.

There is still some air can get in between the wood here. But foam cannot be there as it is so small gap that the head of expanding foam cannot be in.

Later, he put the wood outside and inside covered it.

The outside is seal on the top with waterproof tape, and on the side with cement tube (not silicone)

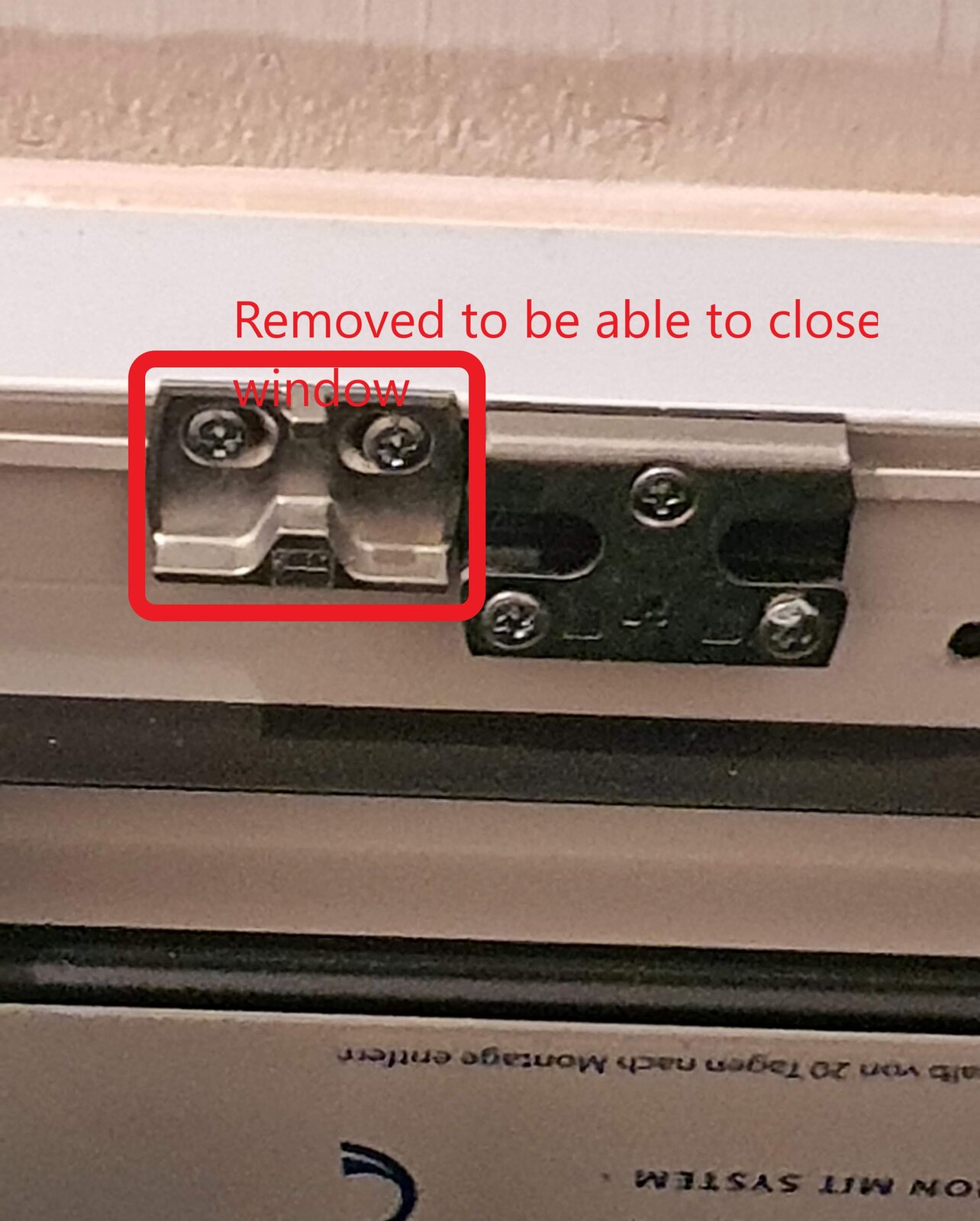

The fitting of the window opening on the left side is quite bad, it is not possible to close at the beginning.

Some attempt to redo fixing frame screw, finally the can close it, but they need to remove the guide to get the last millimeter clear after adjusting all possible range of the window hinge.

The frame is lifted and tilted at this plumb level.

I try to argue that this is not right.

But for the fact that, the window can be closed. They do not fix anything and insist that, this is ok. They do like this for every house.

His argument is the window is heavy, so, the wood can reformed a bit.

I'm worried

- Will I get water issue in the future, after expand and contract of the wood around the window?

- Will the wood reform further and I will not be able to close the window as there is so less clearance for the window to be closed?

- Will cement protect the water to get into my cavity wall? I really doubt that.

- Is the lead strip that is not cover the corner enough to protect the water?

- The fact that, there is no shim , and no place to put foam around the window - will this hole get bigger and bigger and the air and water can get it later?

I hope that I show quite detail for other to see the window installation also.

Anyone with experience please comment. What can be improved?

I still hold last amount of money - but he insist that he did a good job [and he really believe that and proud of his job], nothing can be done further from this side.

I try to put the picture step by step how the worker fitted my window.

They removed the window [with such a mess], and I put picture from the starting of the fitting.

There are leveling wood (orange) in between cavity wall, but is it not fixed to the wall.

On the bottom and top, there are already wood exist.

The installer put wood piece and foam to fix the orange wood on the side.

And put a piece of wood to make it level. (see the top)

It is the same at the bottom, then he put lead strip over it at the bottom. The lead strip is not go up to the side.

The top and bottom are perfect level at this moment. [but not later]

On the other side, he put some wood to level them.

Then the window are put into it, without any sealant on any side.

There is still some air can get in between the wood here. But foam cannot be there as it is so small gap that the head of expanding foam cannot be in.

Later, he put the wood outside and inside covered it.

The outside is seal on the top with waterproof tape, and on the side with cement tube (not silicone)

The fitting of the window opening on the left side is quite bad, it is not possible to close at the beginning.

Some attempt to redo fixing frame screw, finally the can close it, but they need to remove the guide to get the last millimeter clear after adjusting all possible range of the window hinge.

The frame is lifted and tilted at this plumb level.

I try to argue that this is not right.

But for the fact that, the window can be closed. They do not fix anything and insist that, this is ok. They do like this for every house.

His argument is the window is heavy, so, the wood can reformed a bit.

I'm worried

- Will I get water issue in the future, after expand and contract of the wood around the window?

- Will the wood reform further and I will not be able to close the window as there is so less clearance for the window to be closed?

- Will cement protect the water to get into my cavity wall? I really doubt that.

- Is the lead strip that is not cover the corner enough to protect the water?

- The fact that, there is no shim , and no place to put foam around the window - will this hole get bigger and bigger and the air and water can get it later?

I hope that I show quite detail for other to see the window installation also.

Anyone with experience please comment. What can be improved?

I still hold last amount of money - but he insist that he did a good job [and he really believe that and proud of his job], nothing can be done further from this side.