- Joined

- 28 Feb 2020

- Messages

- 2

- Reaction score

- 2

- Country

Hi Folks,

Being a long time "sufferer" of the elusive Turbomax F22 Fault I've set up an account here just to post my as of yet seemingly un-published fix! Posting it here because over the years this site keeps popping up as the closest anyone's got to suggesting but rarely completely resolving the (my) Valiant F.22 fault so rather than append to an old thread I'm bumping a new one.

To avoid any "thou shalt not enter the burner box" we'll just skip past my replacement of Flow/Return NTC sensors, the cheap ones from e-bay and full-priced Valliant ones thinking the former may have been false economy, but I'll mention the Valliant D&G £299 insurance policy 2 years ago that saw at least 5 different Valiant engineers replace the primary Heat Exchanger (blocked), DHW plate heat exchanger, diverter valve, pump head, burner box insulation (destroyed when engineer replaced main HEX) to give me a nearly new boiler (but still faulty when winter came around again).

Having had so many main components replaced under insurance there's no way I was going to write this formerly immensely reliable non-condensing boiler off so my quest to resolve the intermittent Turbomax F22 fault carried on over the last 4 months.

I should also mention I replaced the boiler service valves which weren't isolating, found the expansion vessel to be dead (which was almost certainly the cause of the original HEX blockage not picked up by valliant engineers) so replaced that but to do so had to remove the old flue (only to find it also severely mutilated by said Valiant engineer when she replaced HEX and burner insulation) so a new flue was fitted... oh, and the leaking PRV, filling-loop valve and auto-bypass valve... Love that all these parts are easy to change and still available for a reasonable price!

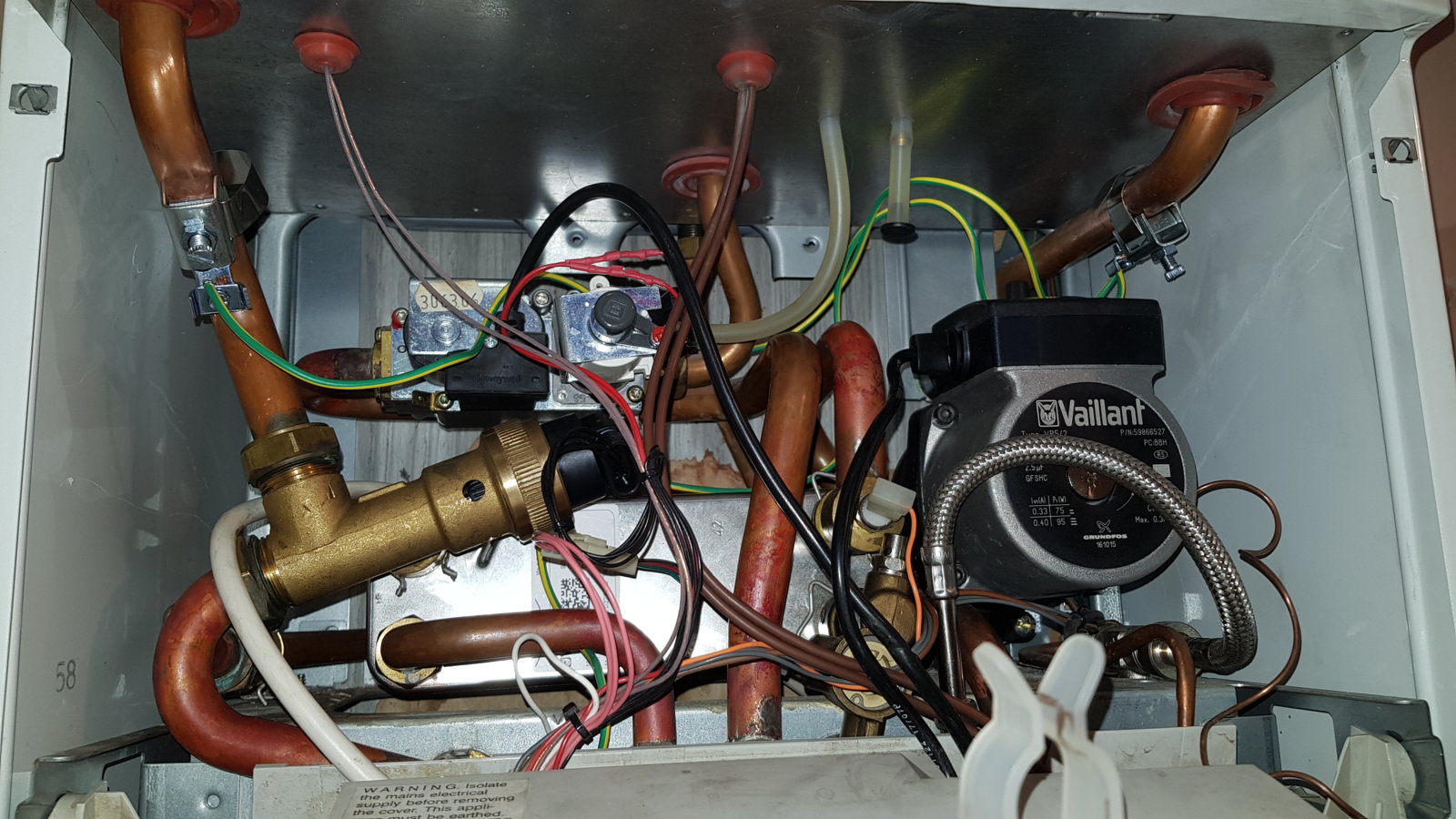

So... back to the F22 fault that started randomly creeping back in, only things left I'd read on here not tried were the somewhat expensive PCB replacement and a burner pressure tweak, but then I happened upon a youtube vid. of a boiler engineer fixing an intermittent problem on a newer valliant that saw the DHW temp rapidly rising on display (causing lockout) but actual water temp. not reflecting display temp. He pointed out that the NTC sensors are single wire and use boiler pipework as an "earth" return to PCB via boiler chassis. After 18 years, the boiler pipes and contact points were hardly prime electrical conductors and on the return sensor there was a good 60 to 70 ohm resistance so I simply used electrical earth straps to bond freshly polished flow and return pipes where they emerge from the bottom of the burner box, directly back to the PCB earth point on the boiler chassis.

Switched boiler off and back on presuming there might be some kind of initial NTC resistance calibration carried out by PCB and it's been running perfectly, DHW is back on and the boiler hasn't had an F22 or any other lock-out since.

Here's to another 20 years of fault-free, service free operation and if there are any of these beauties left in the wild, hopefully the motivation to inspire others to try this extremely simple fix that doesn't even require opening the burner box!

Being a long time "sufferer" of the elusive Turbomax F22 Fault I've set up an account here just to post my as of yet seemingly un-published fix! Posting it here because over the years this site keeps popping up as the closest anyone's got to suggesting but rarely completely resolving the (my) Valiant F.22 fault so rather than append to an old thread I'm bumping a new one.

To avoid any "thou shalt not enter the burner box" we'll just skip past my replacement of Flow/Return NTC sensors, the cheap ones from e-bay and full-priced Valliant ones thinking the former may have been false economy, but I'll mention the Valliant D&G £299 insurance policy 2 years ago that saw at least 5 different Valiant engineers replace the primary Heat Exchanger (blocked), DHW plate heat exchanger, diverter valve, pump head, burner box insulation (destroyed when engineer replaced main HEX) to give me a nearly new boiler (but still faulty when winter came around again).

Having had so many main components replaced under insurance there's no way I was going to write this formerly immensely reliable non-condensing boiler off so my quest to resolve the intermittent Turbomax F22 fault carried on over the last 4 months.

I should also mention I replaced the boiler service valves which weren't isolating, found the expansion vessel to be dead (which was almost certainly the cause of the original HEX blockage not picked up by valliant engineers) so replaced that but to do so had to remove the old flue (only to find it also severely mutilated by said Valiant engineer when she replaced HEX and burner insulation) so a new flue was fitted... oh, and the leaking PRV, filling-loop valve and auto-bypass valve... Love that all these parts are easy to change and still available for a reasonable price!

So... back to the F22 fault that started randomly creeping back in, only things left I'd read on here not tried were the somewhat expensive PCB replacement and a burner pressure tweak, but then I happened upon a youtube vid. of a boiler engineer fixing an intermittent problem on a newer valliant that saw the DHW temp rapidly rising on display (causing lockout) but actual water temp. not reflecting display temp. He pointed out that the NTC sensors are single wire and use boiler pipework as an "earth" return to PCB via boiler chassis. After 18 years, the boiler pipes and contact points were hardly prime electrical conductors and on the return sensor there was a good 60 to 70 ohm resistance so I simply used electrical earth straps to bond freshly polished flow and return pipes where they emerge from the bottom of the burner box, directly back to the PCB earth point on the boiler chassis.

Switched boiler off and back on presuming there might be some kind of initial NTC resistance calibration carried out by PCB and it's been running perfectly, DHW is back on and the boiler hasn't had an F22 or any other lock-out since.

Here's to another 20 years of fault-free, service free operation and if there are any of these beauties left in the wild, hopefully the motivation to inspire others to try this extremely simple fix that doesn't even require opening the burner box!

Last edited: