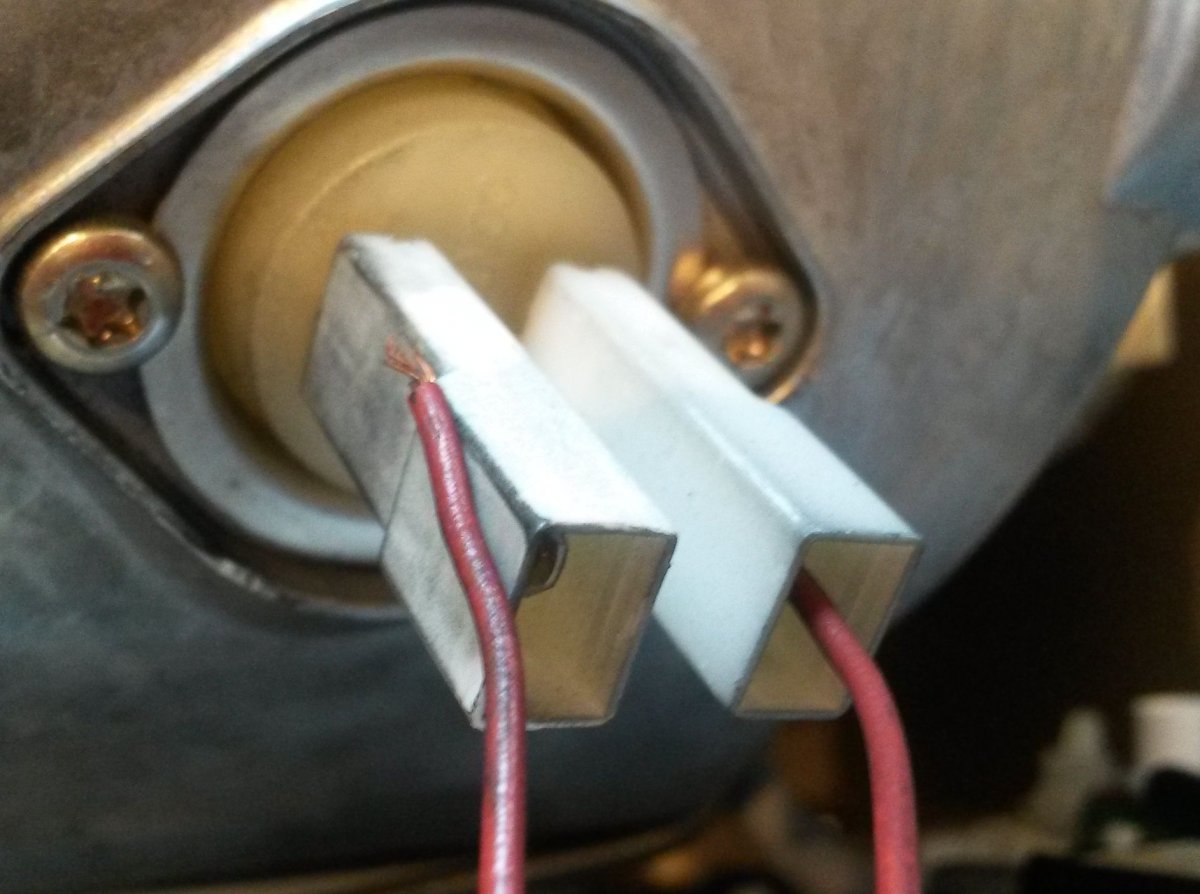

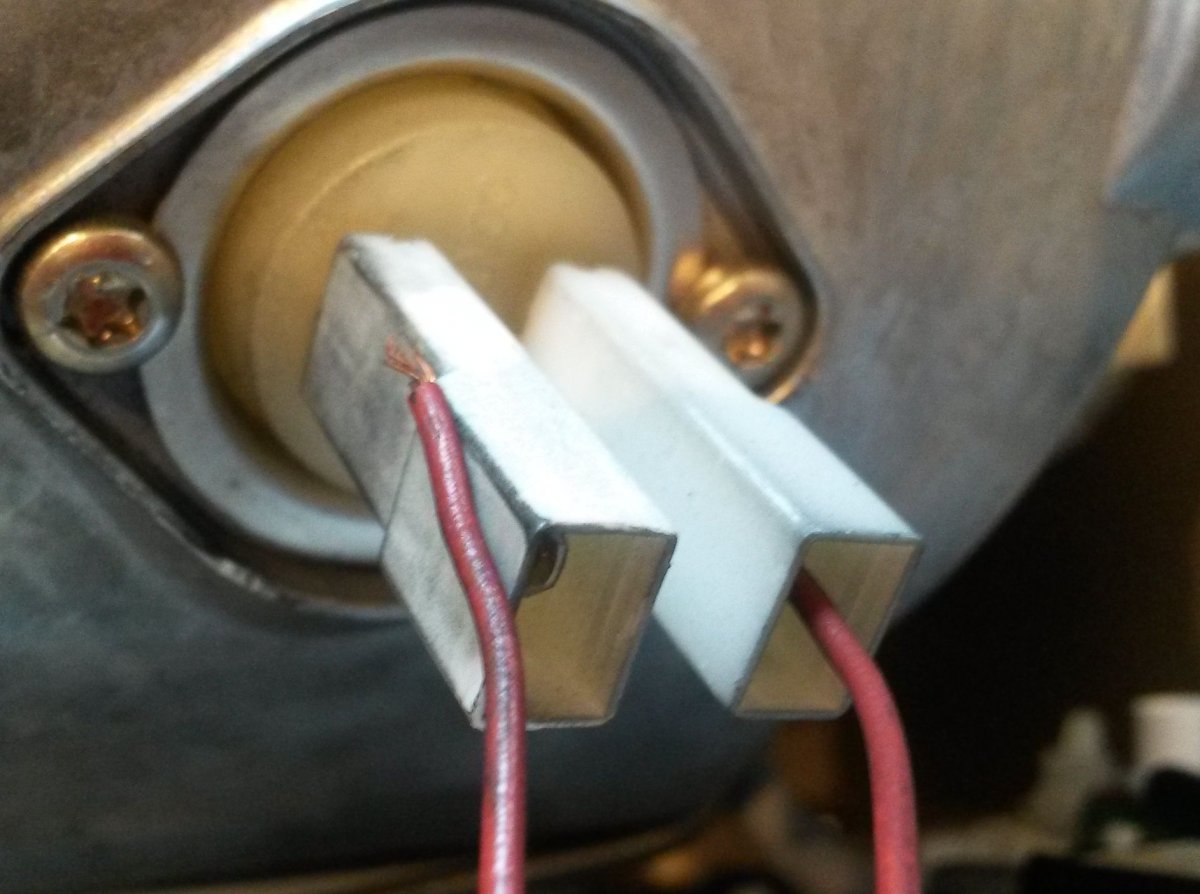

I originally posted this in Appliances and someone replied and suggested I post it here. My washing machine stopped working so I took off the top to see if there was anything obviously wrong. There was some cellophane or plastic that had burnt or melted (see first photo) and underneath I could see a wire has worked loose from the spade connector and the plastic cover, (second photo). Also, elsewhere on the loom there was another scorch mark on the plastic cover and underneath that one of the wires was blackened. Someone suggested it looked as if it was just a case of reconnecting a new spade connector but I should ask in this part of the forum in case there might be something else that could be wrong. Any advice would be appreciated. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Washing Machine Electrics

- Thread starter Talby

- Start date

Sponsored Links

IMO, you did originally ask in the correct place! Appliances should be the place to ask.

However..

It looks like the wire needs properly crimping as it should not just drop off. Melting of the the surroundings will bearesult of the bad concretion. You'd need a proper rachet crimping tool and a new spade connector.

Get the maker involved if the machine is under warranty.

However..

It looks like the wire needs properly crimping as it should not just drop off. Melting of the the surroundings will bearesult of the bad concretion. You'd need a proper rachet crimping tool and a new spade connector.

Get the maker involved if the machine is under warranty.

- Joined

- 27 Jan 2008

- Messages

- 25,007

- Reaction score

- 2,895

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

Taking each picture in turn.

First one the damage to cover can't be seen well enough to comment.

Second one clearly needs a new terminal fitting the type used needs a special set of crimp pliers so I would used a pre-insulated one instead. It seems to connect to a temperature switch but could be wrong.

Third not good enough to comment.

Fourth the black seems to be paint rather than heat damage.

In general washing machines now use programmable integrated circuits to run the machine. Although one can get readers in real terms one has not a clue what is written into the program. I remember early in the days of PLC's working on a machine which had stopped and since the temperature read as zero I felt it should have run. However some one in design had realised the machine should never be at zero degrees so wrote into the program if showing less than 10 degrees stop machine as the sensor must be faulty.

As a result maintenance men have to follow a set of tests laid out by the manufacturer no longer can they jump in and do what seems sensible. Even as an electrical engineer I get my washer repaired by a washing machine repair man rather than DIY. It would just cost too much to get the manuals to know how to test.

Yes I would renew the connector and replace any blown fuse and try it. But after that it would be load into car and take to local repair man. I am lucky car designed to carry wheel chair so easy to wheel in washing machine. If I did not have that car I would pay the extra and get man to visit the house.

With all the modern technology the washing machine works far better than in the past using far less power. But the cost of that technology is DIY repair is very limited.

First one the damage to cover can't be seen well enough to comment.

Second one clearly needs a new terminal fitting the type used needs a special set of crimp pliers so I would used a pre-insulated one instead. It seems to connect to a temperature switch but could be wrong.

Third not good enough to comment.

Fourth the black seems to be paint rather than heat damage.

In general washing machines now use programmable integrated circuits to run the machine. Although one can get readers in real terms one has not a clue what is written into the program. I remember early in the days of PLC's working on a machine which had stopped and since the temperature read as zero I felt it should have run. However some one in design had realised the machine should never be at zero degrees so wrote into the program if showing less than 10 degrees stop machine as the sensor must be faulty.

As a result maintenance men have to follow a set of tests laid out by the manufacturer no longer can they jump in and do what seems sensible. Even as an electrical engineer I get my washer repaired by a washing machine repair man rather than DIY. It would just cost too much to get the manuals to know how to test.

Yes I would renew the connector and replace any blown fuse and try it. But after that it would be load into car and take to local repair man. I am lucky car designed to carry wheel chair so easy to wheel in washing machine. If I did not have that car I would pay the extra and get man to visit the house.

With all the modern technology the washing machine works far better than in the past using far less power. But the cost of that technology is DIY repair is very limited.

Talking of sensors, it looks like that's what this is

So there might be some consequential damage from something not turning on or off when it should have done.

So there might be some consequential damage from something not turning on or off when it should have done.

Sponsored Links

I guess the black plastic used to cover the control unit to cover it from major water leaks.

It may have overheated due to the wiring shorting out.

Fix the spade terminal and see if the washing machine works.

It may have overheated due to the wiring shorting out.

Fix the spade terminal and see if the washing machine works.

Theoretically true. However, that looks like a (probably N/C) temperature sensor (i.e. essentially a 'thermostat'), so its becoming disconnected probably "stopped something "turning on" (the OP said that the machine 'stopped working'), which probably would not have resulted in any consequential damage.Talking of sensors, it looks like that's what this is ... So there might be some consequential damage from something not turning on or off when it should have done.

Kind Regards, John

What wiring has shorted out?It may have overheated due to the wiring shorting out.

I suppose the thought was probably that that loose (and probably live) conductor may have touched some earthed metal?What wiring has shorted out?It may have overheated due to the wiring shorting out.

Kind Regards, John

Does it look like it may have?

No obvious signs, no - but if it had been a modest current which flowed (we don't know where that conductor comes from), perhaps for a very brief period of time, it may not necessarily have left any 'evidence'.Does it look like it may have?

Kind Regards, John

Re-crimped the connection and working as normal. Thanks for the replies and advice.

With all the modern technology the washing machine works far better than in the past using far less power....

Modern machines are hopeless. The energy obsessed idiots in Brussels have forced manufacturers to produce machines that are all about eco nonsense and nothing about practical washing. The wash programs are all geared to getting an A+++ rating. Try finding a machine that does a quick wash for a freshen up with a decent wash load....they don't exist anymore.....meaning you actually have to carry out more wash loads using more energy in the end. AFAIR there is now a Samsung machine that takes 5 hours on one of the programs. You won't even find the wash times for programs in many manuals/specs nowadays....potential customers would be shocked.

That's not a bad thing, per se.AFAIR there is now a Samsung machine that takes 5 hours on one of the programs.

If it does result in lower energy consumption, and you can kick it off when you go to bed or go to work, then it might as well take 5 hours as 5 minutes.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 34

- Views

- 9K