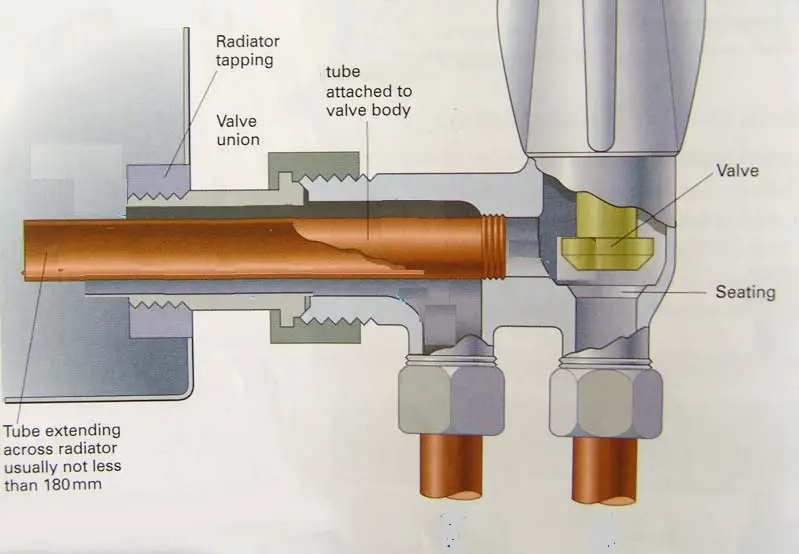

A microbore twin valve is a unique radiator valve that is based on a co-axial principle. It has both the feed and return pipes connected to a single unit at the bottom of one end of a radiator. The idea is simple: The feed pipe is on one connection, while the return is on the other. The connection furthest from the radiator has a valve and a long 8mm pipe screwed into the inner face, providing a directed flow (or return) to reach the far side of the radiator. The connection close to the radiator on the other hand, allows the circulating fluid to exit (or enter) straight out of (or into) the radiator bottom in a more randomised way.

The question is: which way round should the flow and return pipes be connected to the valve in order to provide the best thermal efficiency from the radiator?

Will one way give a more even heat distribution across the entire radiator surface, and if so why?

If you look on the internet, there are diagrams that show both ways, so maybe it doesn’t matter - but I’m sure that there must be some good reasons why one way is better than the other?

Your ideas would be most appreciated...

The question is: which way round should the flow and return pipes be connected to the valve in order to provide the best thermal efficiency from the radiator?

Will one way give a more even heat distribution across the entire radiator surface, and if so why?

If you look on the internet, there are diagrams that show both ways, so maybe it doesn’t matter - but I’m sure that there must be some good reasons why one way is better than the other?

Your ideas would be most appreciated...

Last edited: