- Joined

- 28 Sep 2015

- Messages

- 11

- Reaction score

- 0

- Country

Hi

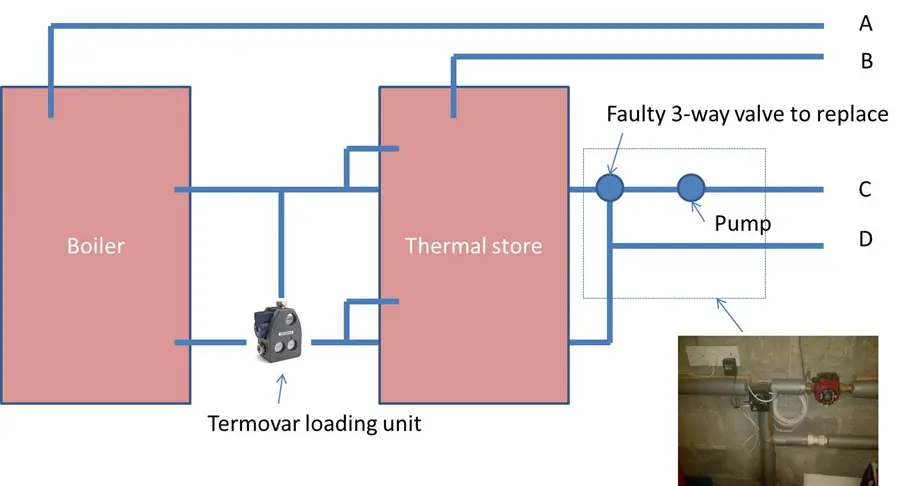

Looking for a bit of help/confirmation of my thinking (as a novice). I've got a wood pellet boiler and thermal store in the garage, that feeds the central heating and hot water. Hot water storage tank and header tank in loft. A three-way mixing valve needs to be replaced so I need to drain down the whole system and previous advice has also suggested fixing isolating valves to make it easier in the future. I think I am fine about how to cut in and fix in the valves but have a couple of questions things to check. I've mapped out the system in the garage (pic below).

Flow - would I be right in thinking that A and B will both be expansion pipes, C as hot water out to house and D as cold in to system from header?

Location of isolating valves - any thoughts on locations?

Type of isolating valves to use - these are all 28mm pipes, copper in majority of the system shown but plastic to right of pump on C and on D. I was looking at full-bore 28mm compression ball valves for the copper areas (is that right and any ideas on where/what is best to get?), but can anyone recommend a product for the plastic sections if needed.

Drain-down - there's a drain valve on the bottom of the thermal store. I'm fine with how to do this but just wanted to check that all I need to do is tie off the ballcock at the header tank?

There's a bit more background on //www.diynot.com/diy/threads/r...ood-pellet-boiler-system.442989/#post-3473620

Anyway, hope this is clear, any help much appreciated.

Cheers

Ben

Looking for a bit of help/confirmation of my thinking (as a novice). I've got a wood pellet boiler and thermal store in the garage, that feeds the central heating and hot water. Hot water storage tank and header tank in loft. A three-way mixing valve needs to be replaced so I need to drain down the whole system and previous advice has also suggested fixing isolating valves to make it easier in the future. I think I am fine about how to cut in and fix in the valves but have a couple of questions things to check. I've mapped out the system in the garage (pic below).

Flow - would I be right in thinking that A and B will both be expansion pipes, C as hot water out to house and D as cold in to system from header?

Location of isolating valves - any thoughts on locations?

Type of isolating valves to use - these are all 28mm pipes, copper in majority of the system shown but plastic to right of pump on C and on D. I was looking at full-bore 28mm compression ball valves for the copper areas (is that right and any ideas on where/what is best to get?), but can anyone recommend a product for the plastic sections if needed.

Drain-down - there's a drain valve on the bottom of the thermal store. I'm fine with how to do this but just wanted to check that all I need to do is tie off the ballcock at the header tank?

There's a bit more background on //www.diynot.com/diy/threads/r...ood-pellet-boiler-system.442989/#post-3473620

Anyway, hope this is clear, any help much appreciated.

Cheers

Ben

Last edited: