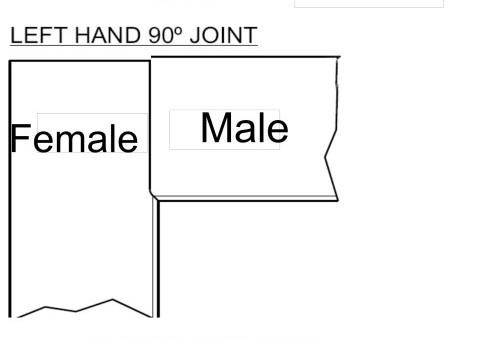

Hi all, new to using a worktop router jig and just purchased a HIB Topform jig and made a few 90 deg mitre joints.

Something slightly puzzling, the jig makes good joints but when bolted up, consistently leaves a 3mm gap at the back of the left/right section. In other words, once the back worktop is pushed up to the wall there is a 3mm gap between the left or right sections and the back wall.

It's not too much of a problem but I wondered if this is normal/acceptable. I can't imagine that a CNC machined jig, no matter how cheap can be out by this amount. In all other respects it is spot on.

Also, as the jig is slippy melamine onto slippy worktop, I find that I can't guarantee that it won't move slightly whilst routing. I'm using quick-grip type clamps but they do apply a fair amount of pressure. Best to use G clamps and pads?

Thanks.

Something slightly puzzling, the jig makes good joints but when bolted up, consistently leaves a 3mm gap at the back of the left/right section. In other words, once the back worktop is pushed up to the wall there is a 3mm gap between the left or right sections and the back wall.

It's not too much of a problem but I wondered if this is normal/acceptable. I can't imagine that a CNC machined jig, no matter how cheap can be out by this amount. In all other respects it is spot on.

Also, as the jig is slippy melamine onto slippy worktop, I find that I can't guarantee that it won't move slightly whilst routing. I'm using quick-grip type clamps but they do apply a fair amount of pressure. Best to use G clamps and pads?

Thanks.