If the testing results show major fault on the motor, could the PCB board be the issue ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beko washing machine motor problem

- Thread starter utterlydiy

- Start date

Sponsored Links

If the testing results show major fault on the motor, could the PCB board be the issue ?

Working from a distance, all anyone can say is that it is either a motor problem, or a PCB issue.

As DIY suggested, usually there will be some sort of fault indication, which might help diagnosis..

If there is major fault on motor, then the motor needs to be replaced majorly. Since the motor runs, fault on it is improbable.If the testing results show major fault on the motor, could the PCB board be the issue ?

As others & you have said, it's a tacho, but if it was faulty you would expect to see an error code either a letter & number or display lights flashing in a sequence. Have you tried running it in diagnostic mode.

Sponsored Links

Will try at weekend when visiting daughters to do a check

Machine has no display, just buttons and leds.

Machine has no display, just buttons and leds.

Machine has no display, just buttons and leds.

Our washer just has a series of LEDs, it flashes the LEDs in a sequence, to show a fault code. Even a single LED, is able to indicate a fault code, via a series of long and short flashes, rather like Morse code. Search online for the fault code of the particular model of machine, for a list.

Hi,

Refitted the motor and tried to enter the diagnostic mode. Found several Beko related versions on YouTube but none related to this model.

One I did find, with machine turned off, main dial in on/off position, while holding Start/Pause button and turn machine on to first position which I assume is 90deg, release and press again, all lights flashing.

Turn dial to position 6 assuming thats Sports with lights still flashing, then press Start/Pause stepping through squences. When first started this procedure the motor started through the various tests with rinse, water in and pump water out as expected.

Tried again, motor back to its original fault as described in earlier posts.

Tried to do the 5 led test which tell which component is at fault on YuoTube. But this applies to another model.

Think its time to get an engineer to sort it and decide if its worth a new motor or new machine Unless you know of another test squence.

Refitted the motor and tried to enter the diagnostic mode. Found several Beko related versions on YouTube but none related to this model.

One I did find, with machine turned off, main dial in on/off position, while holding Start/Pause button and turn machine on to first position which I assume is 90deg, release and press again, all lights flashing.

Turn dial to position 6 assuming thats Sports with lights still flashing, then press Start/Pause stepping through squences. When first started this procedure the motor started through the various tests with rinse, water in and pump water out as expected.

Tried again, motor back to its original fault as described in earlier posts.

Tried to do the 5 led test which tell which component is at fault on YuoTube. But this applies to another model.

Think its time to get an engineer to sort it and decide if its worth a new motor or new machine Unless you know of another test squence.

Has a post about diagnostic mode, for that machine.....

Hi

Sorry to mess you about found this on internet followed and machine now working How to enter test mode Beko washing machine to find the fault

Start by turning the washing machine of with door shut.Now turn the dial to the position 1 Which is normally the 90c hold the start /pause button down while you press the on/off button to on for a couple of seconds till light flashesNow turn the dial to the position 6 and hold down a few seconds the next time you enter it should turn on all the lights now you are in self test diagnostic mode:Every time you Press the on/off button it will change the test function.1st all the lights will show2nd will not do anything3rd This will tell the motor to turn at standard wash speed clockwise with pump emptying.4th This will tell the motor to turn at standard wash speed anticlockwise with pump emptying.5th This will tell the motor to spin clockwise with pump emptying.6th This will activate right hand compartment water valve. Please note machine will keep filling until you stop it.7th This will activate left hand compartment water valve. Please note machine will keep filling until you stop it.8th This will activate booth water valves together. Please note machine will keep filling until you stop it.9th will not do anything10th this will start fill cycle until water activates the pressure switch at normal fill level (Normally just below the glass on the door) when the Beko washing machine has reached the level it will start clockwise rotation at normal wash action and heat the water. Please note You Have to stop it manually.11 this will activate the pump only to empty.Press again and you are back at the start. Turn machine of and leave for a few minutes and the switch back on and you’re in normal wash mode.

Thanks, thats the one I used.

Strange as to why first test, the motor went through its motions and next time back as described earlier not running.

Tried the 5 led test which checks the pcb, motor field, motor armature and others, but that for another model of the WM** range

Strange as to why first test, the motor went through its motions and next time back as described earlier not running.

Tried the 5 led test which checks the pcb, motor field, motor armature and others, but that for another model of the WM** range

Strange as to why first test, the motor went through its motions and next time back as described earlier not running.

I'm not sure what you are saying above...

Are you saying the diagnostics ran the motor up to speed completely satisfactorily, then when you tried to use it normally it was back as before, or something else?

No.

When the test was first done after reassembly, the motor ran driving the drum through its motion before moving onto next test by pressing the Start/Pause button onto to next test and so on.

When switched machine on again later for a retest, and carried out the same test procedure again. The motor did not run and the fault was back as described in my posts.

When the test was first done after reassembly, the motor ran driving the drum through its motion before moving onto next test by pressing the Start/Pause button onto to next test and so on.

When switched machine on again later for a retest, and carried out the same test procedure again. The motor did not run and the fault was back as described in my posts.

Reset again by going through diagnostics then try a spin only program if it's OK then you seem to have an input to the pcb problem ( pressure switch perhaps) if it does not then it sounds increasingly like the control pcb is faulty.

This is another test I tried, but the control layout is for another model.

www.ukwhitegoods.co.uk

www.ukwhitegoods.co.uk

Beko 5 LED Washing Machine Fault Codes

This set of fault codes only pertains to the Beko WM series of washing machines but it may also relate to other Beko models that use the same PCB from Invensys for a controller and have five LEDs used

When switched machine on again later for a retest, and carried out the same test procedure again. The motor did not run and the fault was back as described in my posts.

My approach, would be to repeat the diagnostic test, a few times, interspersed the above test - just to confirm it is not an intermittent problem. If it proves to be not an intermittent issue, then it has to be as jj4091 suggests, a sensor issue....

A common sensor to fail, is the pressure sensor, which detects the water level inside the drum. That takes the form of a small bore pipe, from the lower part of the machine, usually drain pump area, which then rises up to near the top of the machine, and a diaphragm type pressure switch - which looks like a tiny pan shaped object, pipe into it, and a pair of electrical terminals. Water rises up the pipe, applies a tiny amount of pressure to one side of the diaphragm, which operates a microswitch.

To test it, remove the pipe at the lower end, make sure it seems to be clear of obstructions, then blow very gently into the end of the pipe. You should hear a click, as the microswitch operates, as you blow, and again when you stop blowing - obviously with the machine unplugged from the power..

Hello again,

Tried just using Spin in the diagnostics and still same results.

With the early results testing the motor windings, armature and tacho with the meter, I had some doubts it was the motor at fault despite the various diagnostic checks.

So decided to remove the control pcb board.

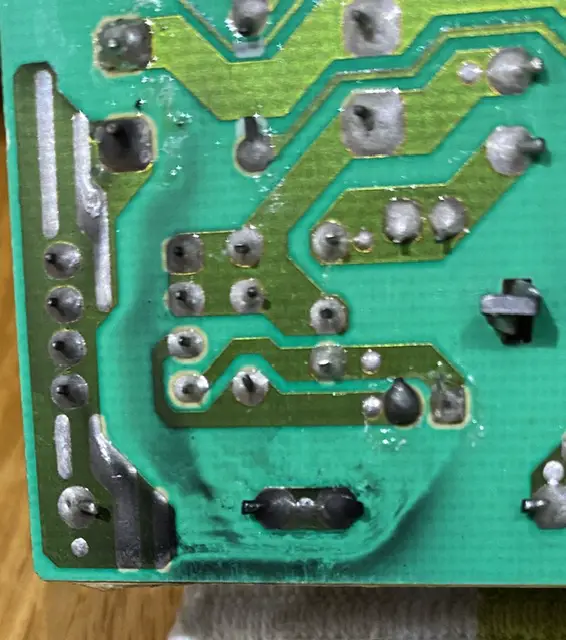

Found what could be the cause of the problem, burnt areas and solder joint on the underside around a capacitor (not the blue one in photo but black one out view to right) and 2 diodes.

Tried just using Spin in the diagnostics and still same results.

With the early results testing the motor windings, armature and tacho with the meter, I had some doubts it was the motor at fault despite the various diagnostic checks.

So decided to remove the control pcb board.

Found what could be the cause of the problem, burnt areas and solder joint on the underside around a capacitor (not the blue one in photo but black one out view to right) and 2 diodes.

Attachments

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 12

- Views

- 11K