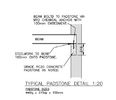

Hello, I've removed a wall between kitchen and dining room. At the external wall, SE has specified beam sitting on top of padstone with M12 chemical anchor, plus an SHS windpost with steel angle, with more bolts between steel angle and RSJ. The other side of the room, the RSJ is on top of 3 cripple studs, so that side is fairly straight forward.

My question is how to get the chemical anchors into the padstone, and then the threads through the RSJ holes?

If I set the anchors in the padstone, then mortar the padstone in place, there's no way to lift the RSJ over the anchors because of the joists above obviously...

Only method I can think of is to acro the RSJ up with holes drilled, put the anchors into the padstone, then put the padstone up through the holes and stuff around with mortar. Leave to set before removing acros.

Attached 2 details of the same end (One of the section details doesn't have the windpost in the drawing but they are both definitely the same end of the RSJ).

Cheers!

My question is how to get the chemical anchors into the padstone, and then the threads through the RSJ holes?

If I set the anchors in the padstone, then mortar the padstone in place, there's no way to lift the RSJ over the anchors because of the joists above obviously...

Only method I can think of is to acro the RSJ up with holes drilled, put the anchors into the padstone, then put the padstone up through the holes and stuff around with mortar. Leave to set before removing acros.

Attached 2 details of the same end (One of the section details doesn't have the windpost in the drawing but they are both definitely the same end of the RSJ).

Cheers!