I'm not an expert in ch but your conclusion is not correct, physics states that the relationship won't be linear in a system containing an incompressible fluid as well as the compressible one where the compressible one is retained to a certain volume of the system (the ev).

As an example if your system is at 1.5 bar and the ev is 99% full of air and 1ml of water, then as soon as you lose more than 1ml of water your pressure will drop in the system below the ev pressure (it will match the static height of the system)

This is why your ev charge is critical.

Someone will come along complaining my terminology doesn't match what they learn in heating circles but from a physics point of view it's correct.

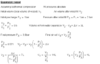

But in your example, the EV precharge pressure is almost 1.5 barg (2.5 bara). There’s no reason to use that. I did some calculations, attached if you’re interested. Let me know if you think I've made any mistakes. If you have Mathcad you put them in and have a play! According to that, the lower the precharge pressure the smaller the total EV volume. And the same for pressure rise on initial (cold) fill. Somebody is welcome to correct me, but my assumption is the expansion vessel is shipped precharged with air to about atmospheric pressure, with obviously atmospheric pressure, 1 bara on the water side. Then top-up water added to give pressure say 1 barg (2 bara). That takes care of static head up to about 10m less a bit for safety, which covers most domestic situations.

Of course boiler manufactures probably use different figures, and have it down to a fine art to minimise cost, but I think that’s the general idea.

But does anybody here know what a typical time is for a sealed system to lose say 0.5 bar and need topping up? 6 months? 12 months? I’m sure 2 – 3 weeks is too short. Or the volume needed to top up?

I accept that if everything is fine there is still some loss, or there’d be no topping up, so that would need to be subtracted from the estimated leakage figure.

On to the physics, the incompressible part is irrelevant to the relation between volume and pressure of the air. For the air, assuming isothermal conditions, volume varies as 1/pressure (Boyle’s law), so reduction in volume is proportional to increase in pressure. But whether it’s linear or not, I don’t think you can get away from saying that if 3 litre water input raises the pressure 0.5 bar, water outflow to cause a drop of 0.5 bar is of the same order. My 3% ignored the expansion of the rads. Linear coeff of expansion of steel = 0.037*10-4, giving change over 80°C = 0.037*10-4*3*80 ~ 0.001 per system volume, or 0.1 litre for 100 litre system. I think we can agree the change due to expansion of the pipes, and compression of the water at the increased pressure, are negligible.