It's a shed and you can make your own decisions, but the standard safety factor for live (removable) load is 1.6. So you actually have to cater for at least 3200 kg. That's one and a half Defender 90s. Plus you'll probably use engine hoists, trolleys or jacks? Those things create punching shear that would just pop straight through a suspended ply sheet. It would be dangerous. The freezer sounds heavy too, especially it's (4?) feet.

Wind aside, I think that you're looking at a substantial concrete floor. Probably >= 100 mm thick with mesh reinforcement and a DPC. Perhaps float finished /screeded if you want it smooth. Any chance it could be ready mixed off a truck? Otherwise that's ~1 m^3 of concrete to mix and it's nice to have it all poured in one go, but not absolutely necessary.

The ground slopes and is soft. That'll have to go (offsite?) and be replaced with compacted Type 1 fill, digging down till you hit firm ground. Dig a test hole outside of the shed's footprint and investigate the ground. This is one of the most important aspects of successful outside construction.

You're really talking about a garage floor.

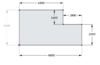

Rotated roofline - but now with a much longer pitch hence more wood. Small 2000 long steel beam possibility?

but now with a much longer pitch hence more wood. Small 2000 long steel beam possibility?

Or, getting a little elaborate in trying to lower the roofline - . Not recommended if at all possible.

. Not recommended if at all possible.

But now a tip. Redraw your sketch to scale. It's quite confusing to have walls 420 and 200 almost the same length

Wind aside, I think that you're looking at a substantial concrete floor. Probably >= 100 mm thick with mesh reinforcement and a DPC. Perhaps float finished /screeded if you want it smooth. Any chance it could be ready mixed off a truck? Otherwise that's ~1 m^3 of concrete to mix and it's nice to have it all poured in one go, but not absolutely necessary.

The ground slopes and is soft. That'll have to go (offsite?) and be replaced with compacted Type 1 fill, digging down till you hit firm ground. Dig a test hole outside of the shed's footprint and investigate the ground. This is one of the most important aspects of successful outside construction.

You're really talking about a garage floor.

Rotated roofline -

but now with a much longer pitch hence more wood. Small 2000 long steel beam possibility?

but now with a much longer pitch hence more wood. Small 2000 long steel beam possibility?Or, getting a little elaborate in trying to lower the roofline -

. Not recommended if at all possible.

. Not recommended if at all possible.But now a tip. Redraw your sketch to scale. It's quite confusing to have walls 420 and 200 almost the same length