Hi there - I have read various posts on calculation of static pressure for various specific systems on the forum. However I am not sure I understand enough about the fundamental issue of static pressure to work out what the static pressure in my system is.

As I understand it static pressure = the resistance gravity imparts to the water in the system, which is relative to the total drop + the resistance of all the fittings in the system.

In my system the boiler is on the ground floor, in the kitchen.

The boiler pipes do several turns to go down into the cellar.

Then they go up to the pump on the first floor and from there in to the diverter valve. The HW tank is also situated next to the pump.

Thereafter the heating circuit branches along for the first floor, up for the second floor and down for the ground floor and cellar. They break into 15mm to feed each rad from a central 22m loop.

There is a 30m run of 15mm pipe branching from the first floor out to a kitchen / bathroom extension at ground floor level. The pipes enter that extensions roof space from the house. They make at least 7 90 degree turns and there are three rads to feed. (I expect this is undersize for the distance - but calculations show it can just, supply enough heat)

The boiler requires 1134L/pr hr to operate and it short cycles quite badly when the house is nearly up to temperature. All the radiators get toasty and I have spent hours balancing the system perfectly with a digital thermometer. (All the windows open to get a good heat sink.) I suspect that the flow rate in the index circuit (The towel rad in the bathroom) is insufficient to remove the heat from the boiler when all the TRV's elsewhere are closing / closed. But no matter, there is a bypass circuit fitted as there should be just after the pump. Four of the Rads control the heat demand to the house via a honeywell CM Zone system.

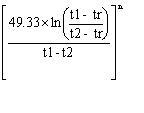

The drop from the top of the rad in the top room to the bottom of the pipe work for the Rad in the cellar is about 8 meters.

At the moment I am trying to solve these problems.

1. Make the boiler not short cycle (20 seconds on 30 seconds off at the moment) Perhaps this is inevitable when most of it's heat is going into the primary loop, as the other TRV's are closed.

2. Ensure that the 30 50 Grundfos pump is actually capable of moving the volume of water round the system at the required flow rate.

3. Set the bypass valve at the correct . bar setting so that all the rads are fed, but the boiler is never starved of water. Obvious really.

4. Set the correct pressure in the system EV in the cellar.

5. Set the correct pressure in the system when cold currently 1 Bar.

6. Work out the correct static pressure in the system

7. Decide if I need to rip out half the kitchen to replace the long 15mm pipe with 22mm pipe or if there is another alternative, boost pump? and use another Rad as the index circuit.

As I understand it static pressure = the resistance gravity imparts to the water in the system, which is relative to the total drop + the resistance of all the fittings in the system.

In my system the boiler is on the ground floor, in the kitchen.

The boiler pipes do several turns to go down into the cellar.

Then they go up to the pump on the first floor and from there in to the diverter valve. The HW tank is also situated next to the pump.

Thereafter the heating circuit branches along for the first floor, up for the second floor and down for the ground floor and cellar. They break into 15mm to feed each rad from a central 22m loop.

There is a 30m run of 15mm pipe branching from the first floor out to a kitchen / bathroom extension at ground floor level. The pipes enter that extensions roof space from the house. They make at least 7 90 degree turns and there are three rads to feed. (I expect this is undersize for the distance - but calculations show it can just, supply enough heat)

The boiler requires 1134L/pr hr to operate and it short cycles quite badly when the house is nearly up to temperature. All the radiators get toasty and I have spent hours balancing the system perfectly with a digital thermometer. (All the windows open to get a good heat sink.) I suspect that the flow rate in the index circuit (The towel rad in the bathroom) is insufficient to remove the heat from the boiler when all the TRV's elsewhere are closing / closed. But no matter, there is a bypass circuit fitted as there should be just after the pump. Four of the Rads control the heat demand to the house via a honeywell CM Zone system.

The drop from the top of the rad in the top room to the bottom of the pipe work for the Rad in the cellar is about 8 meters.

At the moment I am trying to solve these problems.

1. Make the boiler not short cycle (20 seconds on 30 seconds off at the moment) Perhaps this is inevitable when most of it's heat is going into the primary loop, as the other TRV's are closed.

2. Ensure that the 30 50 Grundfos pump is actually capable of moving the volume of water round the system at the required flow rate.

3. Set the bypass valve at the correct . bar setting so that all the rads are fed, but the boiler is never starved of water. Obvious really.

4. Set the correct pressure in the system EV in the cellar.

5. Set the correct pressure in the system when cold currently 1 Bar.

6. Work out the correct static pressure in the system

7. Decide if I need to rip out half the kitchen to replace the long 15mm pipe with 22mm pipe or if there is another alternative, boost pump? and use another Rad as the index circuit.