You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mouting TV bracket to plasterboard wall

- Thread starter masscrazy

- Start date

Sponsored Links

The support bracket will sag when extended with a 30kg load.

The screw bracket is likely to pull away from the stud because it's not long enough to spread the load. In addition, the single stud probably won't take the load. Ideally, you should make a plywood plate to span at least two studs.

If you really must try it, use something inexpensive that weighs 30kg to test it.

The screw bracket is likely to pull away from the stud because it's not long enough to spread the load. In addition, the single stud probably won't take the load. Ideally, you should make a plywood plate to span at least two studs.

If you really must try it, use something inexpensive that weighs 30kg to test it.

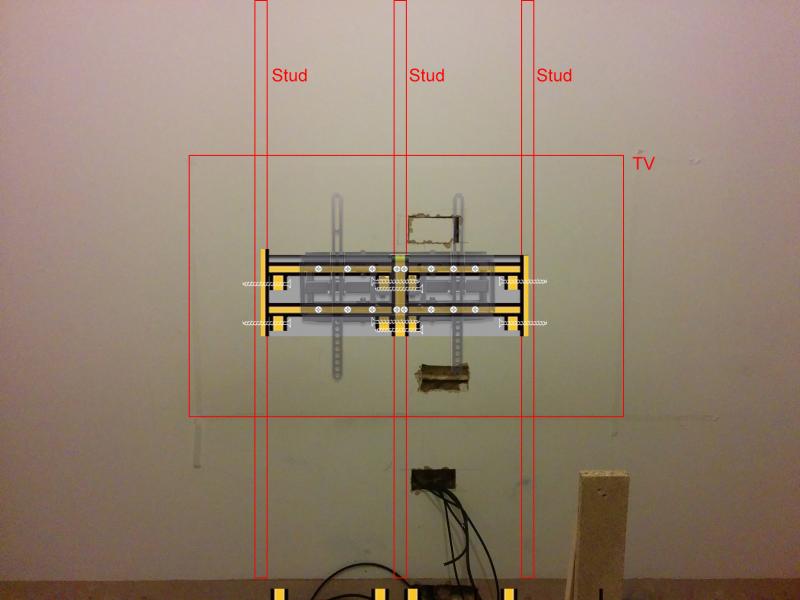

The studs are about 14 inches apart, and have fireblocks between. Its a solid structure but how solid I dont know.

The snaptoggle fittings say they can hold over 100kg on a plasterboard wall.

This image shows its quite a span, in terms of height.

https://images-na.ssl-images-amazon.com/images/I/41BWGlT8xDL._SL1600_.jpg

Or

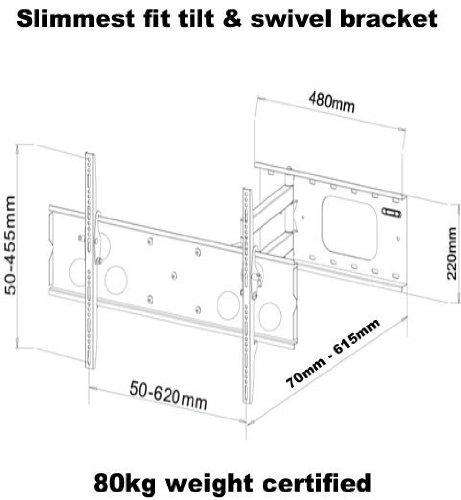

This one, has a wide span. Can use the center 2/3 holes to mount to studs and the remaining 4 (top) and 2 (bottom) use snaptoggles (rated to hold over 100kg).

The snaptoggle fittings say they can hold over 100kg on a plasterboard wall.

This image shows its quite a span, in terms of height.

https://images-na.ssl-images-amazon.com/images/I/41BWGlT8xDL._SL1600_.jpg

Or

This one, has a wide span. Can use the center 2/3 holes to mount to studs and the remaining 4 (top) and 2 (bottom) use snaptoggles (rated to hold over 100kg).

Sponsored Links

Snap Toggles might well be rated for 100kg. That's not the issue. The problem is that

a) there's 30kg of weight hanging off an extension arm that is, at a guess, about half a metre out from the wall. So that's about 15kg of torque trying to rip the plasterboard off the nails holding it on to the studs. That's as well as the effect of the weight of bracket and TV.

and b) the load isn't static. You'll be applying additional force (and stress) each time you move the TV.

Plasterboard is basically chalk and cardboard. It's up to you, but I wouldn't rely on fixings direct in to plasterboard and nothing else for an anglepoise bracket even for a small TV. There will be studs running floor to ceiling to form the framework to which the plasterboard is fixed. As Sam Gange said, span that with something solid, then use whatever fixings you like.

a) there's 30kg of weight hanging off an extension arm that is, at a guess, about half a metre out from the wall. So that's about 15kg of torque trying to rip the plasterboard off the nails holding it on to the studs. That's as well as the effect of the weight of bracket and TV.

and b) the load isn't static. You'll be applying additional force (and stress) each time you move the TV.

Plasterboard is basically chalk and cardboard. It's up to you, but I wouldn't rely on fixings direct in to plasterboard and nothing else for an anglepoise bracket even for a small TV. There will be studs running floor to ceiling to form the framework to which the plasterboard is fixed. As Sam Gange said, span that with something solid, then use whatever fixings you like.

@Lucid - got it, though in the wider bracket I showed a picture of above, the center two holes will be screwed into a stud using these possibly. The remaining holes, 2 either side of the center two, will be attached to plasterboard with snaptoggles or other plasterboard fixing.

Will this make a difference?

Will this make a difference?

It will help, certainly. If you're relying on just two fixings then you need to make sure you hit the mid line of the stud and pre-drill pilot holes to prevent it splitting as the coach bolts drive home.

Just bear in mind that the wall fixing plate will still want to follow any movement in the bracket. So as you swing the TV on the bracket left or right, then the wall plate will want to rotate in the same direction. It will be pushing and pulling on the plasterboard via the attachments at each corner of the bracket. The plasterboard might be strong enough to withstand that for some time, but plasterboard isn't stronger than steel.

In the end it comes down to this - and this isn't aimed at you specifically but it's a general observation of all people coming asking questions about the DIY mounting of TVs on walls - you just want the 'least effort' solution. That's understandable. No one wants to go what they think is OTT. What we'd argue here though is based on the benefit of hindsight. Those of us in the trade know what happens when a job is left half done. It comes back to bite you in the ass. That's why we don't mess about telling you what you want to hear. We just go straight to the correct answer - no detours - a direct route - BAM! We give you what you need to hear. In the end though it's your TV, your wall and your choice.

You've got a solution based on doing what we in the trade would consider to be a risky solution. I wouldn't be happy leaving a client's home with a TV installed that way. But you might be happy with the risk.

Just bear in mind that the wall fixing plate will still want to follow any movement in the bracket. So as you swing the TV on the bracket left or right, then the wall plate will want to rotate in the same direction. It will be pushing and pulling on the plasterboard via the attachments at each corner of the bracket. The plasterboard might be strong enough to withstand that for some time, but plasterboard isn't stronger than steel.

In the end it comes down to this - and this isn't aimed at you specifically but it's a general observation of all people coming asking questions about the DIY mounting of TVs on walls - you just want the 'least effort' solution. That's understandable. No one wants to go what they think is OTT. What we'd argue here though is based on the benefit of hindsight. Those of us in the trade know what happens when a job is left half done. It comes back to bite you in the ass. That's why we don't mess about telling you what you want to hear. We just go straight to the correct answer - no detours - a direct route - BAM! We give you what you need to hear. In the end though it's your TV, your wall and your choice.

You've got a solution based on doing what we in the trade would consider to be a risky solution. I wouldn't be happy leaving a client's home with a TV installed that way. But you might be happy with the risk.

Understood Lucid, so for more structural validity, the way I see it there are few solutions, none are easy and are they sensible...?

Solution 1 - Use 2 wooden batten across 3 studs (3 because I want tv mounted in the center of the 3 studs). And add the mount to that. Will look ugly with 2 wood pieces on the wall and make the TV stick out.

Solution 2 - Same as above but within the wall. Cut the plasterboard horizontally across and a bit beyond 3 studs add 2x4 inch wood batten between the studs. Screw them in directly to the vertical studs and cover with the plasterboard that was originally cut out OR as thick plywood. Then skim.

Both with the intention of using a cantilever (full motion) tv bracket. But this time one that spans a much wide area about 500mm instead of 72mm.

Solution 1 - Use 2 wooden batten across 3 studs (3 because I want tv mounted in the center of the 3 studs). And add the mount to that. Will look ugly with 2 wood pieces on the wall and make the TV stick out.

Solution 2 - Same as above but within the wall. Cut the plasterboard horizontally across and a bit beyond 3 studs add 2x4 inch wood batten between the studs. Screw them in directly to the vertical studs and cover with the plasterboard that was originally cut out OR as thick plywood. Then skim.

Both with the intention of using a cantilever (full motion) tv bracket. But this time one that spans a much wide area about 500mm instead of 72mm.

It's impossible to calculate because you don't know the strength of the wall structure.

As Lucid stated. professionals go for "belt & braces".

If it were mine, I'd fit a floor-to ceiling section of marine ply, at least 12mm thick. The floor would be taking the weight. By the time it was painted, it would be a "feature", not an eyesore. I'd round off and paint at least the edges before final fitting.

As Lucid stated. professionals go for "belt & braces".

If it were mine, I'd fit a floor-to ceiling section of marine ply, at least 12mm thick. The floor would be taking the weight. By the time it was painted, it would be a "feature", not an eyesore. I'd round off and paint at least the edges before final fitting.

The strongest part of your wall is the studs. They run floor to ceiling and they transfer the weight to the rest of the building. Just use a 12mm / 0.5" plywood panel that will cover the width of the studs plus 10cm either side, and that extends higher and 15cm lower and 15cm higher than the vertical footprint size of the bracket.

It's up to you whether you cut out the plasterboard and sink this, or whether you simply screw it to the studs on top. Personally, I'd cut the board, and I'd also cut a hole in the ply to use for cable access. Once the layout is done I'd then glue and screw the panel in place and allow the glue to cure overnight (Gorilla Glue, before you ask). Remember to pilot drill before screwing. You don't want the studs to split. While the glue is drying you can fill up to the edges of the board.

Fixing the board to the studs: Don't try to put two screws into the width of a stud (as per your drawing). You'll weaken the stud and there's more chance of compromising each fixing point. One fixing point done properly is better than two bad ones. Hit the centre of each stud.

For fixings I use these. http://www.screwfix.com/p/rawlplug-intersets-m6-x-37mm-pack-of-20/40813 They're called "intersets". Add larger washers to adequately cover the large fixing holes in the bracket. I prefer these intersets to toggle bolts because the fixing holes are smaller, the anchors have a harpoon-like fixing, and if unscrewed you don't drop half the fixing down the back of the wall. The setting tool is useful if doing a lot or fixing directly in to plasterboard but it's unnecessary when fixing in to ply. Use a hand screwdriver rather than an electric for doing the initial setting.

6 intersets on the top row and four on the bottom row will be more than enough to get the job done.

For power, I'd bring a spur up and set a dry-lining box in to the wall with a switched socket. There's really not much more to be said. You have more than enough detail now to go do the job safely.

Before you go, remember to add your thanks by clicking the Thanks button on EACH post where someone has taken the time to help you. This costs you nothing, and it's a small token of appreciation but a useful one. Do it now. Good luck with the install. Post a pic with an update when you're done [/u]

[/u]

It's up to you whether you cut out the plasterboard and sink this, or whether you simply screw it to the studs on top. Personally, I'd cut the board, and I'd also cut a hole in the ply to use for cable access. Once the layout is done I'd then glue and screw the panel in place and allow the glue to cure overnight (Gorilla Glue, before you ask). Remember to pilot drill before screwing. You don't want the studs to split. While the glue is drying you can fill up to the edges of the board.

Fixing the board to the studs: Don't try to put two screws into the width of a stud (as per your drawing). You'll weaken the stud and there's more chance of compromising each fixing point. One fixing point done properly is better than two bad ones. Hit the centre of each stud.

For fixings I use these. http://www.screwfix.com/p/rawlplug-intersets-m6-x-37mm-pack-of-20/40813 They're called "intersets". Add larger washers to adequately cover the large fixing holes in the bracket. I prefer these intersets to toggle bolts because the fixing holes are smaller, the anchors have a harpoon-like fixing, and if unscrewed you don't drop half the fixing down the back of the wall. The setting tool is useful if doing a lot or fixing directly in to plasterboard but it's unnecessary when fixing in to ply. Use a hand screwdriver rather than an electric for doing the initial setting.

6 intersets on the top row and four on the bottom row will be more than enough to get the job done.

For power, I'd bring a spur up and set a dry-lining box in to the wall with a switched socket. There's really not much more to be said. You have more than enough detail now to go do the job safely.

Before you go, remember to add your thanks by clicking the Thanks button on EACH post where someone has taken the time to help you. This costs you nothing, and it's a small token of appreciation but a useful one. Do it now. Good luck with the install. Post a pic with an update when you're done

It's impossible to calculate because you don't know the strength of the wall structure.

As Lucid stated. professionals go for "belt & braces".

If it were mine, I'd fit a floor-to ceiling section of marine ply, at least 12mm thick. The floor would be taking the weight. By the time it was painted, it would be a "feature", not an eyesore. I'd round off and paint at least the edges before final fitting.

Thanks Sam, I've got a new wood support to help with load distribution. See more details below.

The strongest part of your wall is the studs. They run floor to ceiling and they transfer the weight to the rest of the building. Just use a 12mm / 0.5" plywood panel that will cover the width of the studs plus 10cm either side, and that extends higher and 15cm lower and 15cm higher than the vertical footprint size of the bracket.

It's up to you whether you cut out the plasterboard and sink this, or whether you simply screw it to the studs on top. Personally, I'd cut the board, and I'd also cut a hole in the ply to use for cable access. Once the layout is done I'd then glue and screw the panel in place and allow the glue to cure overnight (Gorilla Glue, before you ask). Remember to pilot drill before screwing. You don't want the studs to split. While the glue is drying you can fill up to the edges of the board.

Fixing the board to the studs: Don't try to put two screws into the width of a stud (as per your drawing). You'll weaken the stud and there's more chance of compromising each fixing point. One fixing point done properly is better than two bad ones. Hit the centre of each stud.

For fixings I use these. http://www.screwfix.com/p/rawlplug-intersets-m6-x-37mm-pack-of-20/40813 They're called "intersets". Add larger washers to adequately cover the large fixing holes in the bracket. I prefer these intersets to toggle bolts because the fixing holes are smaller, the anchors have a harpoon-like fixing, and if unscrewed you don't drop half the fixing down the back of the wall. The setting tool is useful if doing a lot or fixing directly in to plasterboard but it's unnecessary when fixing in to ply. Use a hand screwdriver rather than an electric for doing the initial setting.

6 intersets on the top row and four on the bottom row will be more than enough to get the job done.

For power, I'd bring a spur up and set a dry-lining box in to the wall with a switched socket. There's really not much more to be said. You have more than enough detail now to go do the job safely.

Before you go, remember to add your thanks by clicking the Thanks button on EACH post where someone has taken the time to help you. This costs you nothing, and it's a small token of appreciation but a useful one. Do it now. Good luck with the install. Post a pic with an update when you're done[/u]

Thanks Lucid. So my idea was to place a wooden frame with 2x4 inside the wall that is what the drawing is demonstrating. Think of it as additional fireblocks into which the tv bracket will affix as well as the main stud, with 1 screw not two as in my drawing, as you suggested. But your saying just have plywood across 3 studs. Both ways mean cutting a large hole into the plasterboard. Surely what I'm suggesting can handle more weight?

And this is the new bracket, more weight distribution.

Look at your design. You're basically creating 4 cranks which will want to rotate around the off-centre fixing points, which are 3 screws. Most of your fixing strength comes from the 4 screws in the single centre stud, but the arrangement of those screws side-by-side weakens timber because it almost cuts it in half if they don't miss-align and poke out of the side walls. Now contrast that with the large ply wall plate anchored by glue and (at a guess) 15 screws (5 per) spreading the load across not one but three studs.

It's up to you. Do what you feel works. I've given you the benefit of about £80 in consultancy plus you've had Sam Gangee's assistance. He's another seasoned professional with more than 40 years commercial and domestic install experience. If you feel you have the right solution then go with your gut.

It's up to you. Do what you feel works. I've given you the benefit of about £80 in consultancy plus you've had Sam Gangee's assistance. He's another seasoned professional with more than 40 years commercial and domestic install experience. If you feel you have the right solution then go with your gut.

Look at your design. You're basically creating 4 cranks which will want to rotate around the off-centre fixing points, which are 3 screws. Most of your fixing strength comes from the 4 screws in the single centre stud, but the arrangement of those screws side-by-side weakens timber because it almost cuts it in half if they don't miss-align and poke out of the side walls. Now contrast that with the large ply wall plate anchored by glue and (at a guess) 15 screws (5 per) spreading the load across not one but three studs.

It's up to you. Do what you feel works. I've given you the benefit of about £80 in consultancy plus you've had Sam Gangee's assistance. He's another seasoned professional with more than 40 years commercial and domestic install experience. If you feel you have the right solution then go with your gut.

Ive amended the design slightly [see above]. Now the weight is more evenly distributed. What I'm saying is to use plywood AND a frame, the plywood will be flush against the wall and attached to the three studs and the tv bolted to the center stud and the wood frame behind the plywood... this is now solid right?

Appreciate the help

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 5

- Views

- 1K