- Joined

- 5 Apr 2019

- Messages

- 9

- Reaction score

- 0

- Country

Hi

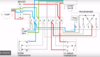

I have a old Thorn Olympic 38/50B boiler which only gets my radiators warm. It would appear that the pump stops when the radiators are look warm, even if I set the boiler thermostat to max and the room thermostat to max. When I operated the pump directly from a separate 240 volt supply the pump runs all the time and the radiators become red hot as they should. Is there a sensor controlling the pump operation?

Thank you for any help given

I have a old Thorn Olympic 38/50B boiler which only gets my radiators warm. It would appear that the pump stops when the radiators are look warm, even if I set the boiler thermostat to max and the room thermostat to max. When I operated the pump directly from a separate 240 volt supply the pump runs all the time and the radiators become red hot as they should. Is there a sensor controlling the pump operation?

Thank you for any help given