- Joined

- 17 Aug 2010

- Messages

- 2,888

- Reaction score

- 506

- Country

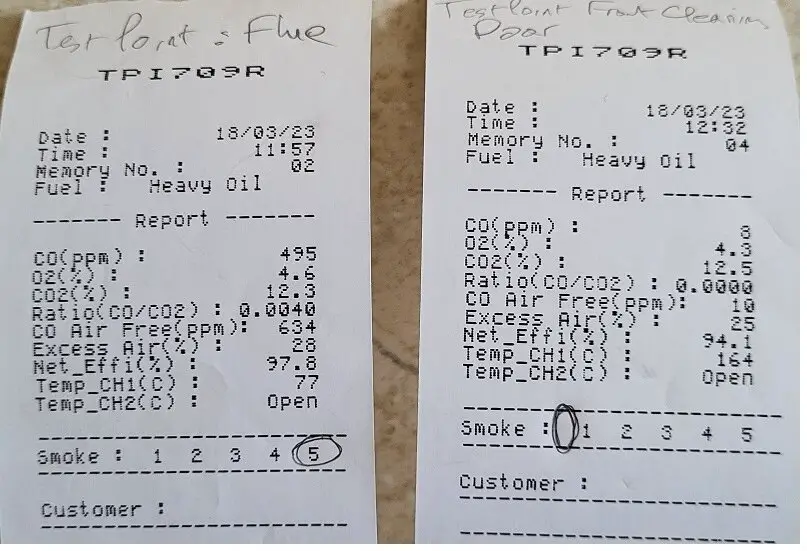

We have a Grant Vortex Eco 15/21, with Riello RDB burner, fitted around 15 months ago. When it stopped working recently, we called in the original fitters who messed us about something wicked, ordering parts and fitting them at random. After about a month with no heating, I decided enough was enough and took it into my own hands. As there was no oil pressure, I ordered and fitted an oil pump, which fixed the problem. I had the opportunity to purchase the commissioning tools without too much personal outlay, so I went ahead and got a smoke tester and a combustion gas analyser. I already had an oil pressure gauge from maintaining an earlier boiler.

So I set up the oil pressure according to the manual, and then set up the CO2 level to 12.5% as specified.

What I found was that if I used the test point in the flue I got really lousy CO and smoke measurements (5). But if I use the test point in the front cleaning door and set to 12.5% CO2, the CO/CO2 ration is 0.0000, and the smoke is barely above 0.

So my question is, why are the combustion measurements in the flue test point so far off? It's a balanced flue in a chimney, and I pushed the probe around half way in.

So I set up the oil pressure according to the manual, and then set up the CO2 level to 12.5% as specified.

What I found was that if I used the test point in the flue I got really lousy CO and smoke measurements (5). But if I use the test point in the front cleaning door and set to 12.5% CO2, the CO/CO2 ration is 0.0000, and the smoke is barely above 0.

So my question is, why are the combustion measurements in the flue test point so far off? It's a balanced flue in a chimney, and I pushed the probe around half way in.