- Joined

- 7 Sep 2022

- Messages

- 4,418

- Reaction score

- 1,263

- Country

warm roof is more complex to do, takes longer and requires more materials. It is best done as a planned exercise during roof construction. Cold roof is simpler; put trusses up, membrane, battens, slate. That gets the place watertight quickly so the finish trades can get on with boarding, plastering, tiling. Insulating is towards the end, just roll out wool on the floor, takes a couple of hours. Creating an insulation layer in warm roof is definitely more than a couple hours work and requires skill and thinking ability beyond rolling out wool (which I frequently see a hash made of too)Is there a good reason why anyone would've opted not to do that in the first place? Why would some one knowingly go for a cold roof setup like this given the choice?

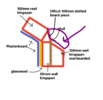

It depends on what other follow up work is done. It's not just about stopping the draught; this area is cold because also you've got that white membrane, then tiles and then world. There is nothing in that buildup that insulates. A warm roof is a composition of an insulated deck, a breathable outer and a vapour barriered inner. The vapour barrier resists human generated moisture from entering the roof build up in the first place. The breathable layer lets out any water vapour that is in there.If I block them up won't I get issues with damp and moisture etc?

A cold roof can deal with huge amounts of moisture (cooking, breathing, drying washing on rads) by huge ventilation. A warm roof deals with small amounts of moisture by small ventilation or breathable fabric, but to make sure it is small moisture you need to barrier a lot of moisture away from entering the roof construction and then deal with this redirected majority another way; PIV, MVHR, ventilation of the warm moist space

Last edited: