You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Should I upgrade central heating pump?

- Thread starter drives

- Start date

Sponsored Links

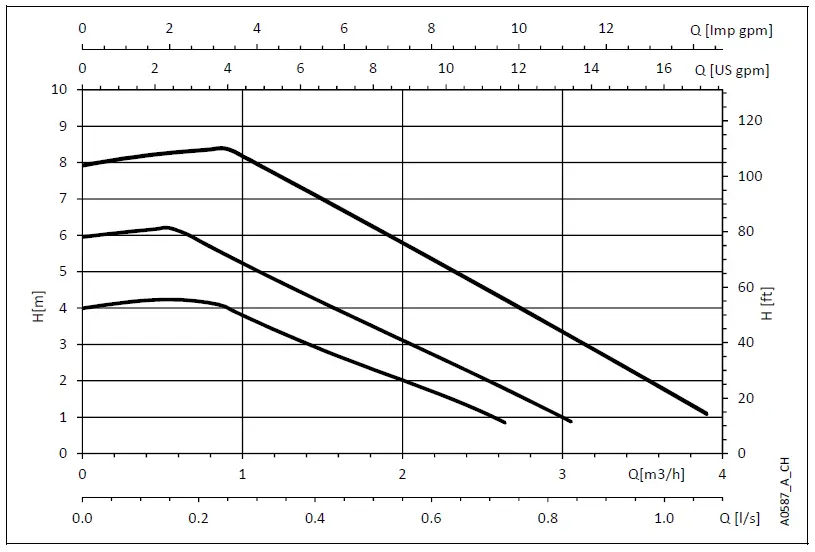

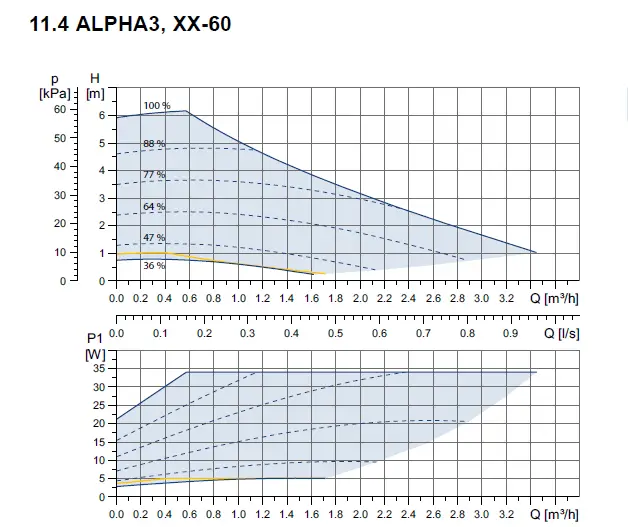

Ecocirc Curve below has the same performance at 6M as most other 6M pumps like the Alpha3.

If you assume tat the 16rads output at a total of 24kw, a rad dT of 15C requires 1LPM so total flow is 24LPM or 1.44m3/hr, say 1.5m3/hr.

Your own pump + the two below all give this flow at ~ 4.0/4.1M.

My only slight concern/suspicion is that the Ecocirc is actually a 6M pump and they achieve a 8M head simply by increasing the RPM, now if this is correct then it may be running at the same speed (at 6M) as your original pump (or even higher) but hopefully won't result in the same problem, Of course the same might apply if you had choosen the Alpha 3 or any other 6M pump.

You may not require a 4/4.1M head so CP or PP settings will result in reduced speed to give the appropriate head if any problems arise.

If you assume tat the 16rads output at a total of 24kw, a rad dT of 15C requires 1LPM so total flow is 24LPM or 1.44m3/hr, say 1.5m3/hr.

Your own pump + the two below all give this flow at ~ 4.0/4.1M.

My only slight concern/suspicion is that the Ecocirc is actually a 6M pump and they achieve a 8M head simply by increasing the RPM, now if this is correct then it may be running at the same speed (at 6M) as your original pump (or even higher) but hopefully won't result in the same problem, Of course the same might apply if you had choosen the Alpha 3 or any other 6M pump.

You may not require a 4/4.1M head so CP or PP settings will result in reduced speed to give the appropriate head if any problems arise.

Ok I think I follow that! I guess my main worry with the Grandfos is that it was just seemed to be three set speed settings. I may be wrong but I did email Grandfos enquiring about this and if they could recommend one of their models. Whilst they did reply, it wasn't massively helpful and didn't answer the question. They just said as my existing pump was heating up the rads at top speed then the problem was my pipes....

Sponsored Links

I don't think you will have any problem with the new pump.

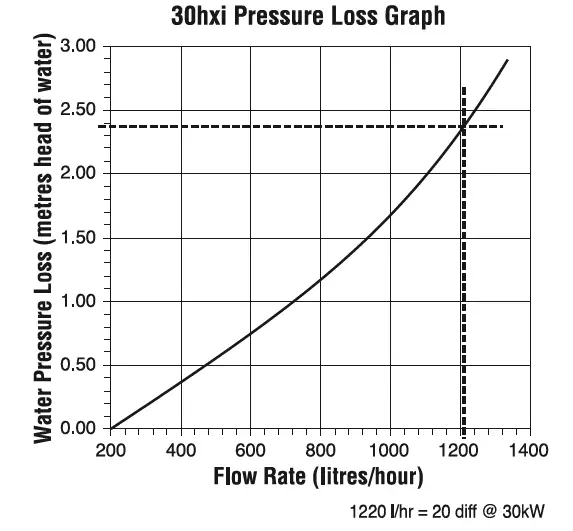

You will often see gas boilers giving a max flowrate based on a 20C boiler dT, your 28kw might have a max flowrate based on this of, 28X860/60/20, 20LPM, 1.2m3/hr and they may also give the pressure drop through the heat exchanger which can often be 2 to 3M so the boiler circ pump has very little remaining head to circulate the water around your system so they generally recommend the installation a low loss header (LLH) with its own pump on the secondary side, the second pump then has plenty of head to circulate the heating system or/and HW coil. Again, some gas boilers have much lower Hx pressure drops than others so you may have little trouble in just using one circulation pump.

Here is a example of a 30kw Glowworm Ultracom HXI which has a dP of 2.4M at 1220LPH, 20LPM, 1.2m3/hr so you can see why 6M pumps can struggle trying to then circulate through the rads after loosing 2.4M through the Hx. An oil fired boiler might only loose 0.25/0.5M through its Hx at this flow.

You will often see gas boilers giving a max flowrate based on a 20C boiler dT, your 28kw might have a max flowrate based on this of, 28X860/60/20, 20LPM, 1.2m3/hr and they may also give the pressure drop through the heat exchanger which can often be 2 to 3M so the boiler circ pump has very little remaining head to circulate the water around your system so they generally recommend the installation a low loss header (LLH) with its own pump on the secondary side, the second pump then has plenty of head to circulate the heating system or/and HW coil. Again, some gas boilers have much lower Hx pressure drops than others so you may have little trouble in just using one circulation pump.

Here is a example of a 30kw Glowworm Ultracom HXI which has a dP of 2.4M at 1220LPH, 20LPM, 1.2m3/hr so you can see why 6M pumps can struggle trying to then circulate through the rads after loosing 2.4M through the Hx. An oil fired boiler might only loose 0.25/0.5M through its Hx at this flow.

Just thought I would come back on this, if it benefits others...

I fitted the Lowara Ecocirc plus pump a couple of weeks back now. All working fine, and the noise from the system in general has dramatically reduced. I no longer get any humming from the pipes under the floorboards and just the mechanical whirring of the actual pump itself in the airing cupboard- therefore in that respect it has definitely been a really good result.

That said, the pump itself- I'm not convinced. The eAdapt function from what I can ascertain at least is pretty useless and just defaults to a setting that is woefully underpowered to circulate the hot water sufficiently through our radiators. I have to have it on speed setting 2 to achieve this so just leave it on that. It also incidentally kept fault coding in that eAdapt setting anyway and switching itself off.

Secondly, the app is also useless. It links via bluetooth to your phone and you can therefore remotely control the settings, but it keeps on changing back to the eAdapt setting after a minute or so, whatever you put it on. It just doesn't work properly and you have to link it every time you want to access the app which takes a good couple of minutes.

All in all, bit irritating that I paid extra for these features and if I could do it again I would probably just get a Grundfos. The pump itself is not amazingly quiet either but whether a Grundfos on a similar speed setting would be better I don't know. Furthermore I emailed Xylem/Lowara to enquire about the issues with eAdapt and their app and they haven't bothered replying.

I fitted the Lowara Ecocirc plus pump a couple of weeks back now. All working fine, and the noise from the system in general has dramatically reduced. I no longer get any humming from the pipes under the floorboards and just the mechanical whirring of the actual pump itself in the airing cupboard- therefore in that respect it has definitely been a really good result.

That said, the pump itself- I'm not convinced. The eAdapt function from what I can ascertain at least is pretty useless and just defaults to a setting that is woefully underpowered to circulate the hot water sufficiently through our radiators. I have to have it on speed setting 2 to achieve this so just leave it on that. It also incidentally kept fault coding in that eAdapt setting anyway and switching itself off.

Secondly, the app is also useless. It links via bluetooth to your phone and you can therefore remotely control the settings, but it keeps on changing back to the eAdapt setting after a minute or so, whatever you put it on. It just doesn't work properly and you have to link it every time you want to access the app which takes a good couple of minutes.

All in all, bit irritating that I paid extra for these features and if I could do it again I would probably just get a Grundfos. The pump itself is not amazingly quiet either but whether a Grundfos on a similar speed setting would be better I don't know. Furthermore I emailed Xylem/Lowara to enquire about the issues with eAdapt and their app and they haven't bothered replying.

I was wondering how you got on.

Does it show how many watts and what flow rate you have?

On the front dial there seem to be three different speed "2" settings, constant pressure, proportional pressure, and constant speed. Have you tried them all?

Did you find this pump yourself or was it recommended?

Does it show how many watts and what flow rate you have?

On the front dial there seem to be three different speed "2" settings, constant pressure, proportional pressure, and constant speed. Have you tried them all?

Did you find this pump yourself or was it recommended?

Three modes are PP A, B, or C. CP 1, 2 or 3 and fixed speed (CC) I, II or III.

It doesn't show what these settings are, apart from the fixed speed ones, but no matter. I would just, very briefly, write down the current M, m3/hr and W (watts) then very briefly switch to the other settings and note the same data for each one (total of 6), can then derive the PP range, and maybe then get a more appropriate setting than the present CC2.

I have only come across one pump where auto adapt, which is a PP mode, appears to work in some fashion at least and that is a Tucson.

The problem with all the others seems to be that they start at the lowest PP setting which is hopeless and are then supposed to "historically" work out over a period of time, the correct PP setting, I think the Tucson just start in the middle which sounds far more logical?.

It doesn't show what these settings are, apart from the fixed speed ones, but no matter. I would just, very briefly, write down the current M, m3/hr and W (watts) then very briefly switch to the other settings and note the same data for each one (total of 6), can then derive the PP range, and maybe then get a more appropriate setting than the present CC2.

I was wondering how you got on.

Does it show how many watts and what flow rate you have?

On the front dial there seem to be three different speed "2" settings, constant pressure, proportional pressure, and constant speed. Have you tried them all?

Did you find this pump yourself or was it recommended?

I have only come across one pump where auto adapt, which is a PP mode, appears to work in some fashion at least and that is a Tucson.

The problem with all the others seems to be that they start at the lowest PP setting which is hopeless and are then supposed to "historically" work out over a period of time, the correct PP setting, I think the Tucson just start in the middle which sounds far more logical?.

That said, the pump itself- I'm not convinced. The eAdapt function from what I can ascertain at least is pretty useless and just defaults to a setting that is woefully underpowered to circulate the hot water sufficiently through our radiators. I have to have it on speed setting 2 to achieve this so just leave it on that. It also incidentally kept fault coding in that eAdapt setting anyway and switching itself off.

Thanks- yes so I did cycle through the various options and is was the constant speed one that got all the rads up to temp. The other ones didn't seem to do this.I was wondering how you got on.

Does it show how many watts and what flow rate you have?

On the front dial there seem to be three different speed "2" settings, constant pressure, proportional pressure, and constant speed. Have you tried them all?

Did you find this pump yourself or was it recommended?

Flow rate is 1.29 m3/h and watts is 38.1. I have no idea if that's good, or expected for a system our size but I will definitely take your advice and cycle through them again and make a note of the readings.

In terms of pump choice, I called Anchor Pumps who seemed to have a decent selection. In fairness, very helpful on the phone and rapid delivery. I told them I ideally wanted a pump with gradual incremental speed setttings if one was available rather than just 3- they directed me to the Ecocirc that I was looking at anyway but clearly the dial doesn't operate exactly as I, or the person advising me, understood that it would do.

All said and done, my wife used to jest that it sounded like an aircraft taking off when our heating kicked in. It wasn't that bad, but it wasn't far off and in terms of what the new pump has done to the comfort of our own home and not being woken up when our CH starts at 0500, it is great. Goes to show how much racket an old pump can make even when the pump itself doesn't actually seem that noisy.

You might just check the head as well, which I think it also displays?.Thanks- yes so I did cycle through the various options and is was the constant speed one that got all the rads up to temp. The other ones didn't seem to do this.

Flow rate is 1.29 m3/h and watts is 38.1. I have no idea if that's good, or expected for a system our size but I will definitely take your advice and cycle through them again and make a note of the readings.

Also, just check the readings with the pump mode set to PP 3 and then CP 3, it will only take a minute or so.

I would be a bit surprised if CP 3 at least didn't give similar performance as CC 2.

Didn't see your bit about cycling through and noting the readings, again.

Its inconceivable IMO that a 8M pump will not give a far higher head at your measured flowrate, above while in CP3 mode. your readings will be most informative.

Last edited:

So...

PP setting 1: 1.27m. 0.69m3/h. 7.9w

PP setting 2: 3.21m. 1.02m3/h. 20.4w

PP setting 3: 5.07m. 1.30m3/h. 37w

CS setting 1: 3.60m. 1.13m3/h. 23.9w

CS setting 2: 5.26m. 1.29m3/h. 38.1w

I tried it on PP setting 2 and it didn't seem to be quite enough to get all the rads warm but I do need to sort out balancing as I've had so many rads on and off over the last year or so whilst renovating, and replacing the odd one for a towel rail in the bathrooms.

PP setting 1: 1.27m. 0.69m3/h. 7.9w

PP setting 2: 3.21m. 1.02m3/h. 20.4w

PP setting 3: 5.07m. 1.30m3/h. 37w

CS setting 1: 3.60m. 1.13m3/h. 23.9w

CS setting 2: 5.26m. 1.29m3/h. 38.1w

I tried it on PP setting 2 and it didn't seem to be quite enough to get all the rads warm but I do need to sort out balancing as I've had so many rads on and off over the last year or so whilst renovating, and replacing the odd one for a towel rail in the bathrooms.

Last edited:

PP setting 2 too low as its only producing a 3.21 M head and 1.02m3/hr.

PP3 would be a reasonable setting IMO if your original CC2 data of 1.29m3/hr at 38.1W satisfies your requirements with everything, PP3 will then reduce the head required as the TRVs or zone valves close in leading to reduced power consumption. CP2 is almost exactly the same as CC2? so again would be a good choice IMO. You didn't include any readings for CP setting 3?.

PP3 would be a reasonable setting IMO if your original CC2 data of 1.29m3/hr at 38.1W satisfies your requirements with everything, PP3 will then reduce the head required as the TRVs or zone valves close in leading to reduced power consumption. CP2 is almost exactly the same as CC2? so again would be a good choice IMO. You didn't include any readings for CP setting 3?.

PP setting 1: 1.27m. 0.69m3/h. 7.9w

PP setting 2: 3.21m. 1.02m3/h. 20.4w

PP setting 3: 5.07m. 1.30m3/h. 37w

CP setting 1: 3.60m. 1.13m3/h. 23.9w

CP setting 2: 5.26m. 1.29m3/h. 38.1w

CP2 seems to be exactly the same as the figures you gave above for CC2? Are they the right way round?

Yep good spot sorry got CP mixed up with constant speed which is the setting I have it on at the moment...edited the post which I believe is now correct.CP2 seems to be exactly the same as the figures you gave above for CC2? Are they the right way round?

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 3

- Views

- 4K