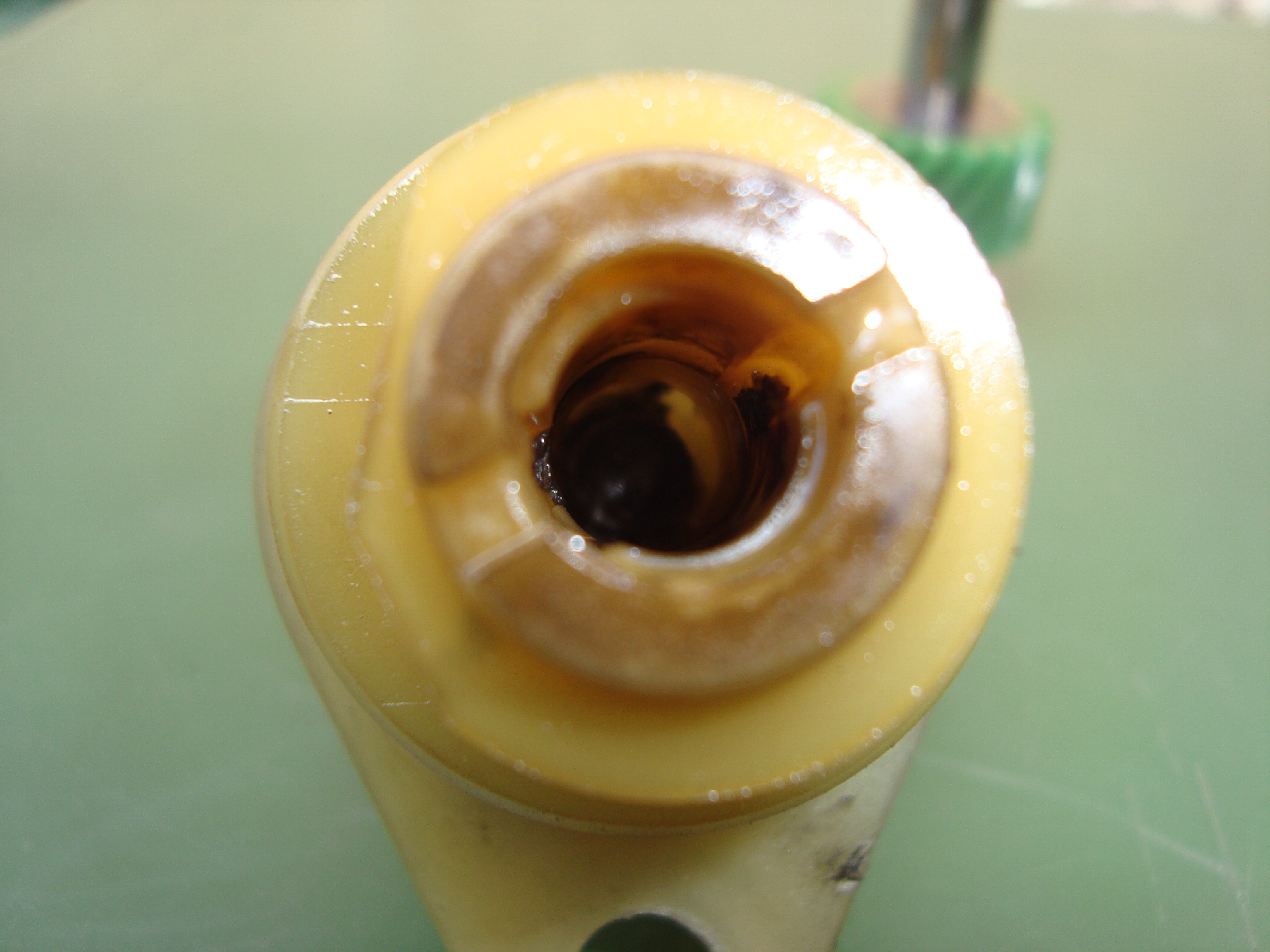

The image below show what it looks like inside the hole where the shaft goes on the new/wrong sensor I bought. You can just make out a square drive inside the hole that my original doesn't have. This square drive stops the gear shaft going fully up into the sensor where it needs to be (original shaft being used, one isn't supplied with new sensor).

I've bitten the bullet and going back to ramp place on Monday. I'm going to pull the old sensor and shaft out again, and put the new one in minus the gear shaft. Then I can have the old sensor and gear shaft to hand to compare and get a compatible one.

Phoned Fiat dealers and they can supply sensor for £130 plus Vodka And Tonic. But there's no guarantee this one won't be wrong like the Febi one I bought. Give me strength!!

I've bitten the bullet and going back to ramp place on Monday. I'm going to pull the old sensor and shaft out again, and put the new one in minus the gear shaft. Then I can have the old sensor and gear shaft to hand to compare and get a compatible one.

Phoned Fiat dealers and they can supply sensor for £130 plus Vodka And Tonic. But there's no guarantee this one won't be wrong like the Febi one I bought. Give me strength!!