I haven't actually tested this, but I imagine things would proceed something like this:-Wouldn't this kind of drastic pressure escape up the (unrestricted) return?

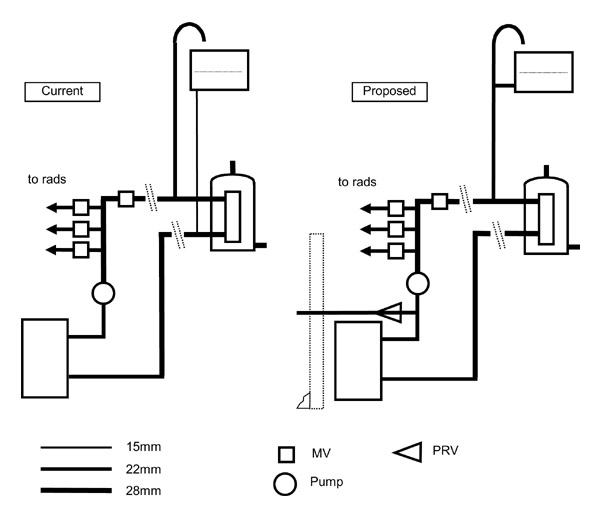

Boiler stat fails, water reaches boiling point (100+C), steam bubbles form and rise up flow pipe. Initially these will collapse on contact with cooler water (with attendant banging noises) but as all temps continue to climb steam pushes up flow pipe and displaces water. But steam cannot escape to vent due to closed MV.

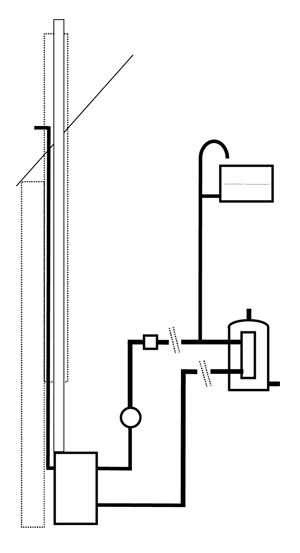

More steam is produced and more water displaced until the upper part of the boiler heat exchanger is dry. Temperature then climbs well above boiling point, but at some point condensing steam causes water to enter super-heated part of boiler. This water flashes to steam very violently and with huge increase in volume, causing sudden increase in pressure. Pipes back to feed tank are not large enough to relieve this sudden increase in pressure which then fractures boiler or pipework.

Also quite likely that sudden temp changes when metal at say 200C is doused with water will caused fracturing of cast iron heat exchanger. Once the boiler or pipework is fractured, the high pressures will be released, causing the boiling point of water to suddenly drop back to 100C (opposite of pressure cooker effect). Large volume of water at say 110C turns instantly to steam. Huge volume increase demolishes surrounding structures and causes severe skin burns to anyone in the vicinity.

Sleep well, Goodnight....