I've got a customer with a planer thicknesser. It currently will not run.

It is a single phase machine with a 4hp motor and a DOL start stop with overload.

There is also another thing in with the contactor, which I don't know what it is.

At the moment when you try and start the machine, it'll run for about 5 seconds before the overload trips.

Measured with my clamp meter, it's drawing about 80A, so clearly something is not right.

The motor bearings seem fine and really free, and the windings test out ok.

There are two 100μF capacitors in parallell connected to the bottom left terminal of the contactor overload, and to the top left connection of the unknown thing.

The capacitors both test out as being dud, but I don't know if this is a symptom or the cause of the problem.

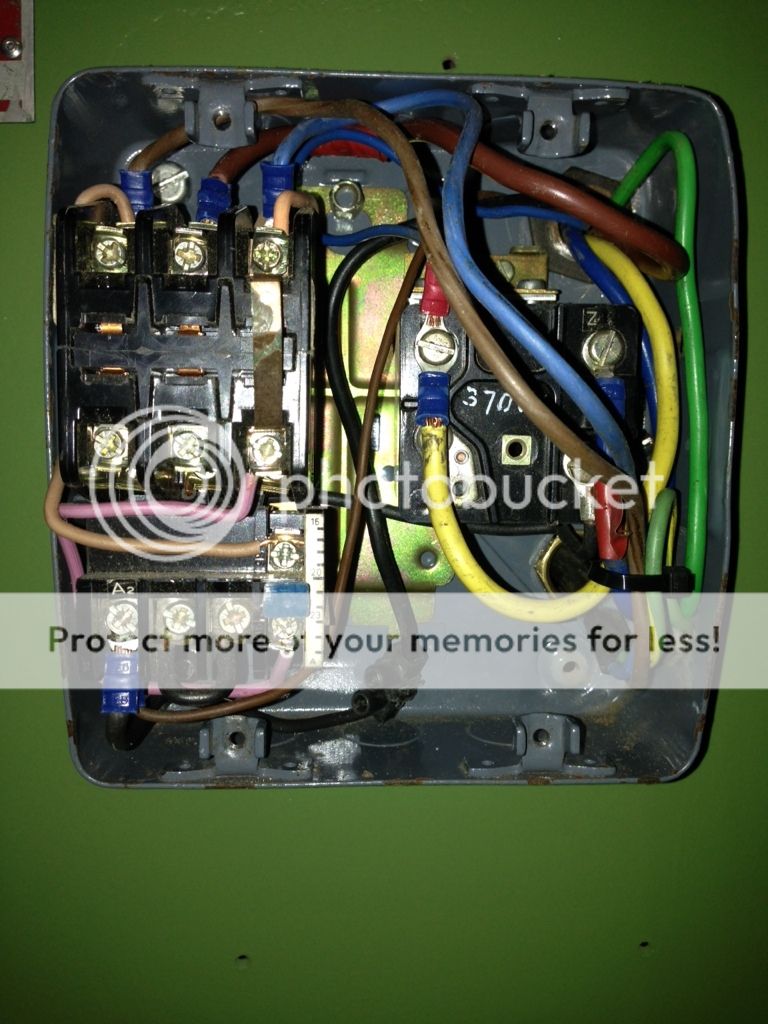

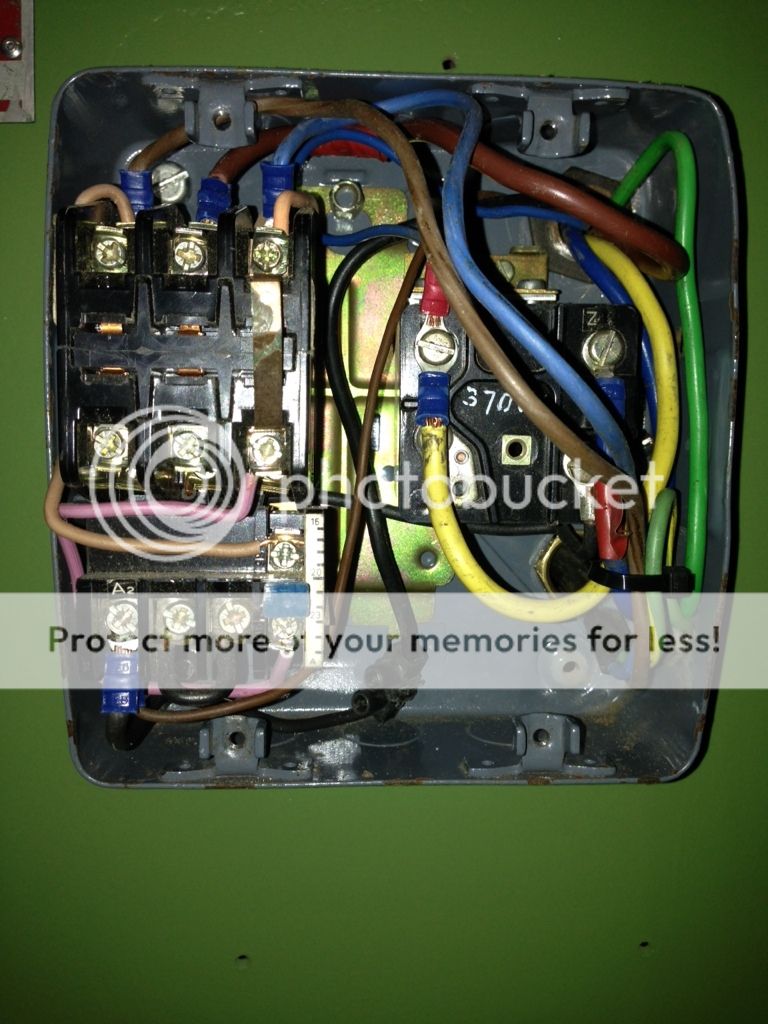

Here's the overall starter:

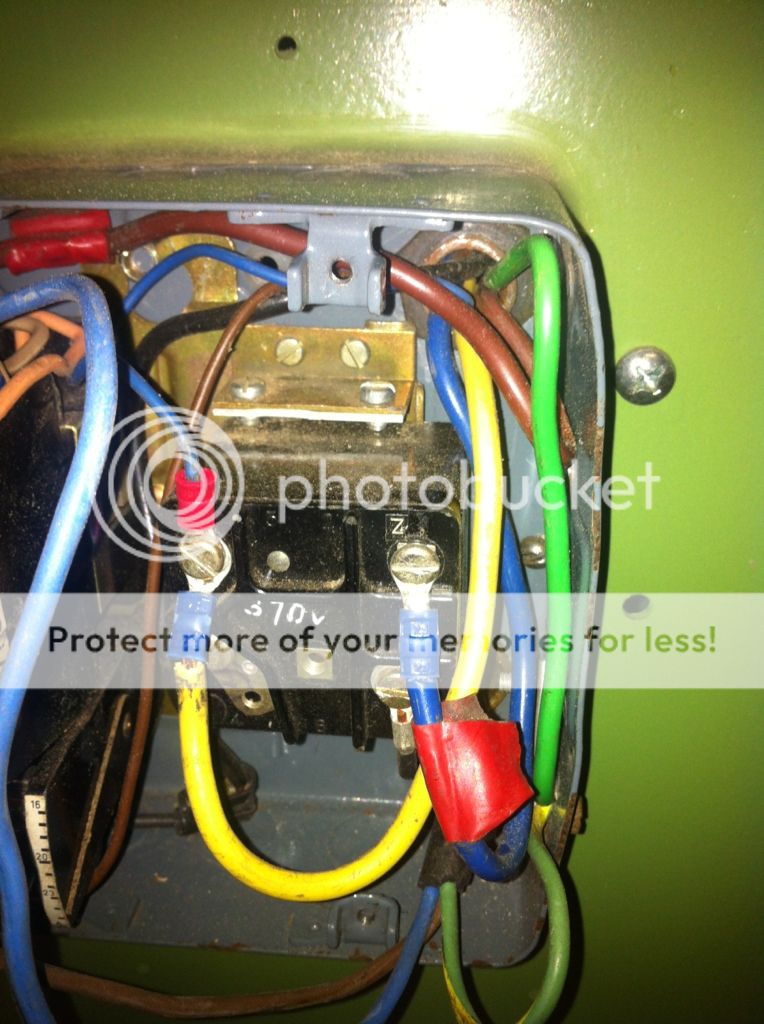

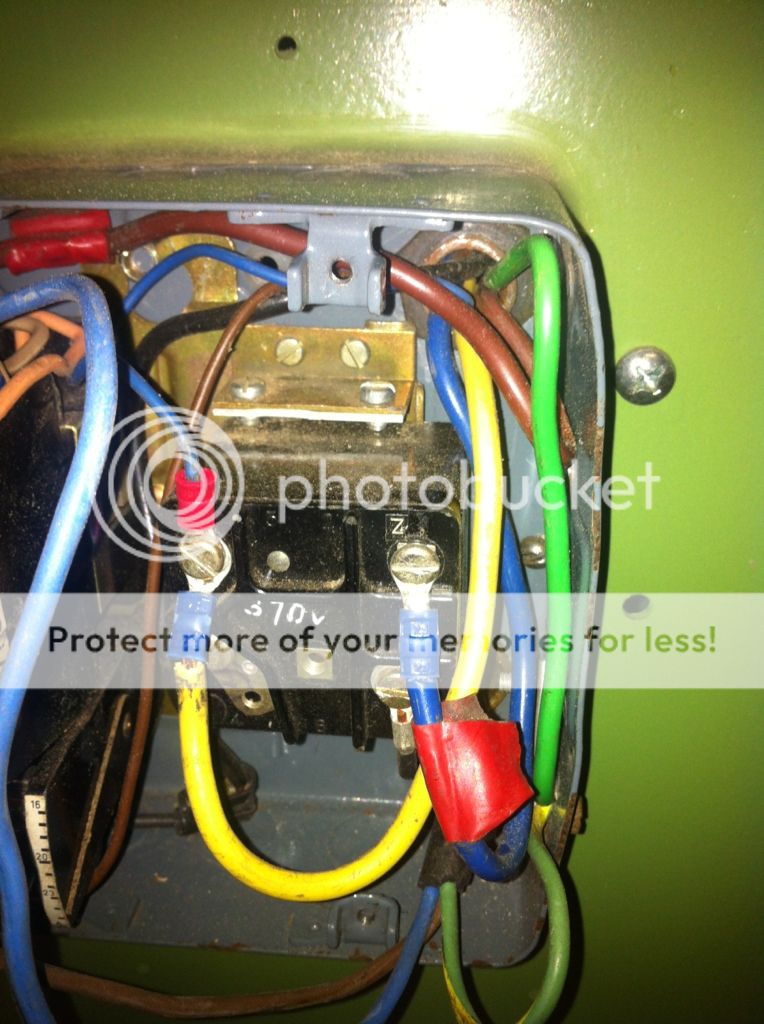

Here's the device I don't know what it is. It sits to the right of the contactor as seen above:

It is a single phase machine with a 4hp motor and a DOL start stop with overload.

There is also another thing in with the contactor, which I don't know what it is.

At the moment when you try and start the machine, it'll run for about 5 seconds before the overload trips.

Measured with my clamp meter, it's drawing about 80A, so clearly something is not right.

The motor bearings seem fine and really free, and the windings test out ok.

There are two 100μF capacitors in parallell connected to the bottom left terminal of the contactor overload, and to the top left connection of the unknown thing.

The capacitors both test out as being dud, but I don't know if this is a symptom or the cause of the problem.

Here's the overall starter:

Here's the device I don't know what it is. It sits to the right of the contactor as seen above: