Firstly, for the benefit of anyone who may wonder what you are talking about, I have virtually never heard PVC insulated and sheathed cables being described as "TPS" cables in the UK.

The is

no UK requirement for the CPC ('earth') conductor of fixed wiring cables to be insulated - if there were, then virtually every electrical installation in the UK which used multi-core cables would be in violation of that requirement!! The requirement for an insulated CPC/'earth' only applies to flexible cables (e.g. 'appliance cords').

.... if you are referring to the bit about core colours, that is just

plain wrong. Whoever wrote it seems to think that, when we changed to 'harmonised' identification colours for fixed wiring (on 31 March 2004), the UK also acquired a requirement for the CPC of fixed wiring to be insulated. That is

NOT true. In other words, the final column the first row of this is wrong....

View attachment 163255

I think there are probably pros and cons of having bare CPCs in fixed wiring. One advantage is that it increases the probability that something penetrating a cable and coming in contact with a live conductor will also come in contact with the CPC, thereby hopefully causing a protective device to operate.

Solid conductors do not needed to be 'twisted' at all, and twisting together of two of them is regarded as bad practice.

I've never handled it, but I suspect that your cables are more flexible 'overall', leading to a requirement for more ('time consuming') cable support?

Kind Regards, John

Oops.

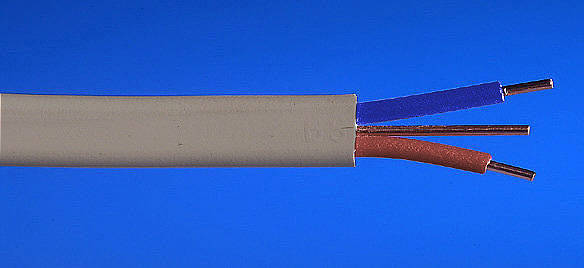

We may have a language problem here. Normal Australian nomenclature is TPS but the North Americans call this cable NM (Non Metallic [insulation] in their weird way) or by the Trade Name of "Romex" - which has some paper "insulation" in its construction and so cannot be used outdoors.

Yes "There is

no UK requirement for the CPC ('earth') conductor of fixed wiring cables to be insulated " - which was

exactly the burthen of my comment.

You and others should all note that everyone has the ability to "correct" any reference in Wikipedia as you see fit so to do.

(If you do so you run the risk that someone else may "correct" you, and so it goes.)

You stated "Solid conductors do not needed (sic) to be 'twisted' at all, and twisting together of two of them is regarded as bad practice."

Really? How could you combine two conductors in the rear of one socket outlet without twisting them together? (Please explain.)

Your statement of "I think there are probably pros and cons of having bare CPCs in fixed wiring. One advantage is that it increases the probability that something penetrating a cable and coming in contact with a live conductor will also come in contact with the CPC, thereby hopefully causing a protective device to operate." is quite 'problematic'.

You seem to consider that no insulation on the Earth conductor within a cable is better than some insulation on that conductor because inadvertent penetration by a metallic object is somewhat more likely to produce a fault condition.

You also wrote "Whatever, I presume that all of us in the UK can agree that 'the norm' remains for the CPC in multi-core fixed-wiring cables to be bare, usually with G/Y sleeving at the ends. I don't even know whether one can get 'fixed wiring multi-core cables' (i.e. not flex) in the UK which has an insulated CPC, can one?"

Yes. I know that that is so.

However, there are other countries where an insulated CPC is the "Norm" and is required in these countries. Hence, insulated sleeving at the ends is not required and the additional cost is minimal.

Another point that I mentioned is that the North Americans do not require any such end sleeving, which can cause them some problems with their relatively primitive electrical connections.

You stated "I suspect that your cables are more flexible 'overall', leading to a requirement for more ('time consuming') cable support?"

The only time when "cable support" (presumably, via "cable clips" et al) would be significant would be where it could be seen. Within a building structure such spacing would be dictated by the spacing of the studs, joists etc.

Australian regulations indicate a spacing of not more than 350 mm between such cable clips.

At this point, I am reminded of a reference where an Electrical Inspector inspected a shed on a farmer's property and commented that the "wiring" was probably not done by an "electrician".

"How so?" asked the farmer.

The inspector replied. "Because it is too neat."