OK, a couple of diagrams for you to ponder over.

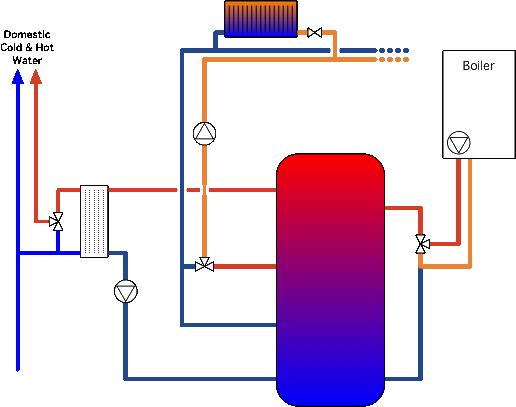

First off, this is a general arrangement as I'd do it - but not including any controls over DHW PHE primary flow as yet - and I've also omitted the F&E tank for clarity. The colour should give you an indication of the sort of heat profile you should normally be trying to achieve in the store to maximise the ability to use the solar panel input (not shown).

This differs slightly from the earlier schematic as it shows the TMV in the boiler loop as a diverter rather than mixer. In this mode, the TMV senses the flow temperature, and divert some (or all) of it to the top of the store when it's hot enough - and the rest back to the boiler return.Heat bank basic arrangement

- SimonH2

- 3

Basic arrangement for a heat store. No control of primary flow in DHW PHE risks destratification...

The key difference here is that you are controlling the flow temperature while the return is "what it ends up at", while a mixer controls the return temperature and the flow becomes "what it ends up at". There are pro's and cons both ways.

The divert arrangement will give you better control over store temperature. The main downside is you only have indirect control over boiler return temp and in particular you cannot quite guarantee not to go cold enough to avoid condensing. You would normally set the boiler on max, and rely on setting the flow to give the delta-T you want and hence the return temperature. In practical terms, for a given flow rate and a given boiler output, you will get a constant delta-T.

The mixing arrangement means you can control the return temp and thus avoid condensing. The downside is you have only indirect control over flow temperature. You can however take advantage of a modulating boiler and let it give some control over flow temp.

I chose the mixing arrangement for my current setup (non-condensing boiler) - I'd choose a divert arrangement with a condensing boiler. I actually have a couple more ideas, but I'll leave them out.

A secondary consideration is that in mixer mode, it should be within the range of a relatively cheap TMV sold for tempering DHW supplies - I picked some up off an "online auction site". In divert mode, you'll need a different valve as this would normally be well above the range of a DHW TMV.

Please can you tell me what valve spec I should be looking for?

The CH system should be fairly self explanatory.

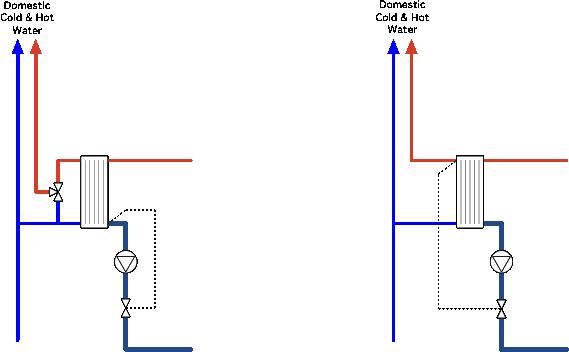

On the next I've shown a couple of ideas for controlling primary flow in the DHW PHE.

On the left I've got it throttling the flow based on the PHE outlet temp. It will still heat the DHW up to near store temp, so you still need the TMV on that side as well.Control options round DHW PHE

- SimonH2

- 2

A couple of potential control valve options to restrict primary flow and avoid destratification.

How it should work is that the flow will be controlled so that as the DHW flow rate varies, and hence the cooling effect on the primary, the valve will adjust the flow rate to suit.

What type of valve is this? I did say I am not a heating engineer.

I'd be looking to set it a little above the prevailing cold water supply temp - I'd guess 10˚C higher would be a reasonable starting point and experiment from there. You may need a bypass round the pump to avoid dead-heading it at very low DHW flow rates.

Note that the sensor bulb ? ideally needs to be inside the PHE port so that it can sense the temperature even if the valve has fully shut and there is now flow - otherwise you could find a situation where the DHW goes cold until the pipes lose a bit of heat and the valve starts allowing some flow.

On the right is an arrangement where the primary flow rate is controlled from the DHW flow temperature. It will only admit as much primary flow as is required to heat the DHW to setpoint.

Note that neither of these is a good solution from a control engineering POV. Controlling PHEs by varying flow rate is very difficult to do accurately and stably so it's generally avoided if possible. Normally you would aim to keep the primary flow rate high and vary the loop temperature as this gives good control - which is the starting point in the thread I linked to earlier. Because the temperature differential between primary input and secondary (DHW) output tends to be quite small if you keep the primary flow rate high, you can in fact get quite good control of secondary (DHW) temperature by only controlling primary loop temperature - thus eliminating the TMV in the DHW side.

That's the arrangement in teh diagram here if you imagine the lower PHE isn't there.

With a single PHE though, this means the primary water you return to the store will be quite warm (or even hot) most of the time - although at a much lower flow rate than with an uncontrolled flow.

This is one reason I went with a thermal store rather than heat bank in the flat.

Sorry, for not replying sooner, got distracted last few weeks. Thanks very much for all of your very helpful input. Another question, I notice in some of your diagrams, the pump on the hot flow side, does it matter where the pump should be fitted? I thought it was best for pump life if on the cool side ie. the return to boiler or TS?

In your last schematic for connecting the condensing boiler to the TS, you showed an auto bypass valve, does this need to be a particular spec?