Happy New Year!

This post is for anyone interested in researching options for a DIY thermal store.

Parts list:

£430 300l standard Telford buffer, comes with dual stat, TPRV, 3kW electric immersion

£145 Nordic Tec Ba-23-40 165kW plate exchanger with insulation

£52 FS-05 flow switch 22mm compression

2 x £50 for Grunfos Alpha 2 pumps used from eBay.

Pipe and fittings.

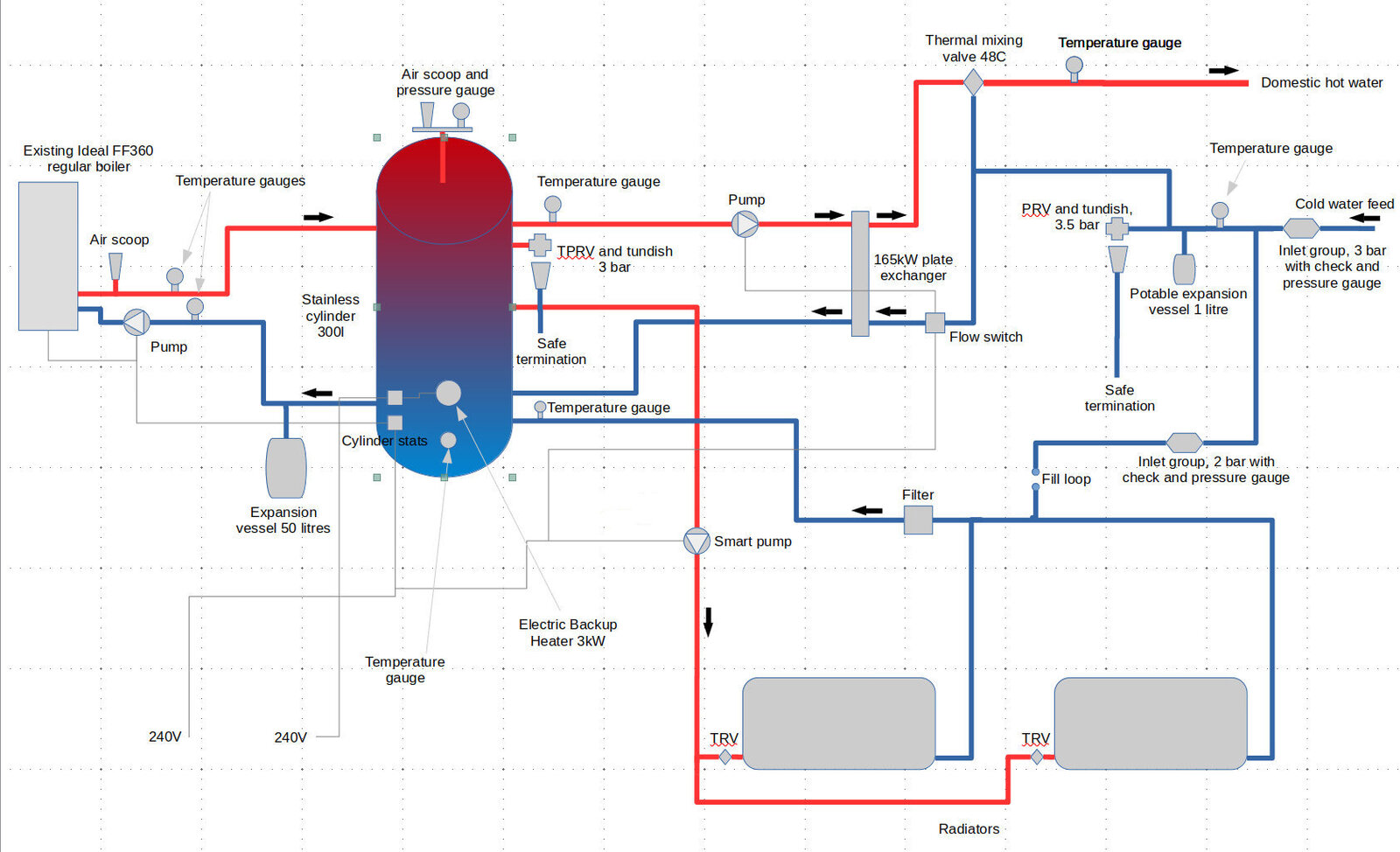

The Telford tank is stainless, and has two 22mm connections at the top on the side, one 1/2" at the very top, two 22mm on the side at the bottom, two stat pockets towards the bottom, a TPRV, and a spot for an immersion heater which is included with the tank. It would have been nice to be able to fit a top and bottom thermometer, and to have one or two connections half way up. Other than that, it seems pretty nice, and is reasonably well insulated, with a modern looking white cover.

The boiler is controlled by the cylinder stat, and the radiators are all controlled by TRVs, with the smart pump supplying more flow when more are open. There is no house stat.

The 165kW plate exchanger works well with the tank stat set to 60C in winter, although we don't have such a great pressure (2.2bar) or flow rate (10 liters/minute) so YMMV. We no longer run out of hot water, although our previous vented cylinder was much smaller at 120 liters. The boiler no longer cycles constantly when the heating is on.

Control wise it is very simple, just a simple cylinder stat controlling the boiler, although it should work well with smart TRVs as each rad is essentially its own zone. It is very easy to control the temperature in each room.

Attached is the system layout.

This post is for anyone interested in researching options for a DIY thermal store.

Parts list:

£430 300l standard Telford buffer, comes with dual stat, TPRV, 3kW electric immersion

£145 Nordic Tec Ba-23-40 165kW plate exchanger with insulation

£52 FS-05 flow switch 22mm compression

2 x £50 for Grunfos Alpha 2 pumps used from eBay.

Pipe and fittings.

The Telford tank is stainless, and has two 22mm connections at the top on the side, one 1/2" at the very top, two 22mm on the side at the bottom, two stat pockets towards the bottom, a TPRV, and a spot for an immersion heater which is included with the tank. It would have been nice to be able to fit a top and bottom thermometer, and to have one or two connections half way up. Other than that, it seems pretty nice, and is reasonably well insulated, with a modern looking white cover.

The boiler is controlled by the cylinder stat, and the radiators are all controlled by TRVs, with the smart pump supplying more flow when more are open. There is no house stat.

The 165kW plate exchanger works well with the tank stat set to 60C in winter, although we don't have such a great pressure (2.2bar) or flow rate (10 liters/minute) so YMMV. We no longer run out of hot water, although our previous vented cylinder was much smaller at 120 liters. The boiler no longer cycles constantly when the heating is on.

Control wise it is very simple, just a simple cylinder stat controlling the boiler, although it should work well with smart TRVs as each rad is essentially its own zone. It is very easy to control the temperature in each room.

Attached is the system layout.