I got the chance to run some lines down from the existing roof to see exactly where the rafters will finish up and they are slightly further over than i thought which means they would meet the wall at fairly high level if they were to run full distance. Given this would it be better to run the rafter to a plate fixed to the face of the wall or still go with the valley rafter?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do i understand my roof structure correctly?

- Thread starter padstar

- Start date

Sponsored Links

What does this mean?they would meet the wall at fairly high level if they were to run full distance.

They meet where they meet and that is where the valley rafter goes.

Sponsored Links

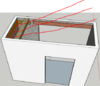

Now that i have fully set out the lines from the existing roof down the rafters will sit as below if they are run through and not into a valley rafter. Is that better/easier than the valley rafter. I will be ordering the material this week so wondered what way to go.

Attachments

The triple timber beam on your picture will potentially be taking a lot of weight (think snow load), you’d need to get a calc done for it and build it in, I’d be v surprised if you can just sit it on top of a timber bolted to the surface. But as above, surely the valley rafter is the way to go and avoid having to worry about it.

Timber has just been delivered ready for me to make a start on the roof at the weekend. I have found a handy website that calculates the rafters and depths etc for me to use but nowhere seems to do the same for valley rafters.

Is the valley rafter the same as the hip from the adjacent corner? They both run from the same ridge point to the wall plate in the same direction? This is the last piece i need to get my head round before i start the work.

Section over the garage above. The valley rafter needs to then link in to the right. Would it be the same as the yellow hip rafter shown above?

Is the valley rafter the same as the hip from the adjacent corner? They both run from the same ridge point to the wall plate in the same direction? This is the last piece i need to get my head round before i start the work.

Section over the garage above. The valley rafter needs to then link in to the right. Would it be the same as the yellow hip rafter shown above?

I had a go at cutting a template rafter this evening just to get a feel for it. 1st attempt i ended up with a rafter for a 60' pitch roof rather than a 30'!. Trip back to the bench and 10 minutes later it went up a treat against an temp ridge board. I am now looking forward to the real thing at the weekend but a have a few questions if you could help it would be great.

1) My seat cut sits perfectly flat on the wall plate but the plumb cut is 1-2mm out. Its against a temp ridge board tonight but how much play is acceptable? Is this too much?

2) I have removed a course of blocks from the outer skin but the pitch means that the rafter still catches about 1" of the top of the block. Is it best to take a grinder to the block at each rafter location or notch out the rafter around the block?

3) I installed the restraint straps this evening and may have been a bit heavy handed with fixing them down. It has caused the wall plate to lift at one end by about 3-4mm on 1 edge. Will the weight of the structure push this back down or do i need to remove the straps and reset 1st.

Sorry for the questions but i think i am nearly there.

1) My seat cut sits perfectly flat on the wall plate but the plumb cut is 1-2mm out. Its against a temp ridge board tonight but how much play is acceptable? Is this too much?

2) I have removed a course of blocks from the outer skin but the pitch means that the rafter still catches about 1" of the top of the block. Is it best to take a grinder to the block at each rafter location or notch out the rafter around the block?

3) I installed the restraint straps this evening and may have been a bit heavy handed with fixing them down. It has caused the wall plate to lift at one end by about 3-4mm on 1 edge. Will the weight of the structure push this back down or do i need to remove the straps and reset 1st.

Sorry for the questions but i think i am nearly there.

Where’s the ridge board in your pic, the blue line?

1) Last time I offered up a pair of identical (common) rafters either side at each end of the ridge board and adjusted the ridge board a bit to get it all to fit, if your walls are square it shouldn’t need much adjustment

2) notch the rafter

3) yeah probably if it’s only a few mm

1) Last time I offered up a pair of identical (common) rafters either side at each end of the ridge board and adjusted the ridge board a bit to get it all to fit, if your walls are square it shouldn’t need much adjustment

2) notch the rafter

3) yeah probably if it’s only a few mm

What is it?website that calculates the rafters and depths

What is it?

Website is https://www.blocklayer.com/roof/rafter.aspx Just input a few dimensions and it calculates everything for you including a full roof setting out plan. Cut to their details and it all went perfectly. Just doesnt mention valley rafters on there.

Thanks everyone

I had about 4-5 hrs on the roof this afternoon. I got the lifted wall plate fixed down and then managed to get all of the common rafters cut and in place. Made a jig for the scribe round the outer skin of brickwork that worked well but measured marked and cut each of the rafters individually. Thoroughly enjoyed this and it was far easier than i had expected (i know i have the hip and jacks left which will be more complicated).

I was concerned that everything needed to be mm perfect but then as i was going realised this is not possible as each timber was different, each rafter was hand marked and cut free hand but when it all came together i think it came out a treat.

I have only fixed each rafter with 1 nail at top and bottom in case you guys point anything out that needs to be changed. If you think it looks ok i will fix them all in the morning (3 nails to each top and bottom?) and then move onto the hip and jacks.

I left the overhangs oversized so that i can get an accurate string line from the blockwork and cut them all once finished.

The calculator i used allowed for a fillet above the higher wall plate. I didn't realise this which is why the rafters finish above the board. Is this actually needed or will the tile just fly past?

Is a course of bricks to the outer skin between the rafters required? I assume so.

Thanks for all your help. Still need to get my head round the valley . . . .

The calculator i used allowed for a fillet above the higher wall plate. I didn't realise this which is why the rafters finish above the board. Is this actually needed or will the tile just fly past?

I was concerned that everything needed to be mm perfect but then as i was going realised this is not possible as each timber was different, each rafter was hand marked and cut free hand but when it all came together i think it came out a treat.

I have only fixed each rafter with 1 nail at top and bottom in case you guys point anything out that needs to be changed. If you think it looks ok i will fix them all in the morning (3 nails to each top and bottom?) and then move onto the hip and jacks.

I left the overhangs oversized so that i can get an accurate string line from the blockwork and cut them all once finished.

The calculator i used allowed for a fillet above the higher wall plate. I didn't realise this which is why the rafters finish above the board. Is this actually needed or will the tile just fly past?

Is a course of bricks to the outer skin between the rafters required? I assume so.

Thanks for all your help. Still need to get my head round the valley . . . .

The calculator i used allowed for a fillet above the higher wall plate. I didn't realise this which is why the rafters finish above the board. Is this actually needed or will the tile just fly past?

Whats holding and restraining the rafters at the top to prevent them sliding?? And they don't look like they are against the wall, how will the top tile batten be fixed?

(You would normally fix the ledger plate below the rafters so that they sit on it, and it only needed to be a 4x2, and then the rafter peak sits against the wall)

Is that end rafter spaced differently?

The cuts look nice

You may want to strap that plate down centrally over the door opening befor you start banging with the roof tiles

(You would normally fix the ledger plate below the rafters so that they sit on it, and it only needed to be a 4x2, and then the rafter peak sits against the wall)

Is that end rafter spaced differently?

The cuts look nice

You may want to strap that plate down centrally over the door opening befor you start banging with the roof tiles

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 10

- Views

- 4K