Thanks again for the feedback - it is genuinely appreciated and apologies for the delay responding. It also takes me a while to work out the answers to some of the questions!

So... we're starting to push the limits of my knowledge and understanding of the system... but this is what I believe to be true and I've tried to take photos to back that up (or be corrected!)

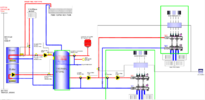

@cross thread Yes - we have two expansion pipes. One from the thermal store and one from the woodburner feed, just before the pump.

@mcmoby69 You don't know how pleased I am to hear that we don't need to raise the height of the f&e tank

The copper tank was sized at the time - but for the life of me I can't find the spec - from memory, 60 litres sounds about right.

Good spot with the ballofix - no idea why it was nearly closed, but I've opened it now.

@oldbutnotdead It was only a small amount of mould around the base of the f&e tank, on the platform it sits on. From observing today, I suspect it is caused by condensation on the lid of the f&e tank running down the outside of the tank. I've added another photo, but hope this is relatively trivial - solve the 'pumping over' and this goes away.

You put "

Might be worth dropping the level in the tank a bit (long as level stays above top of highest primary appliance it'll be fine).". I assume you mean f&e tank - but I'm not sure how to do this to any great extent without changing the ballcock and arm. Is that what you meant, or is there another way to temporarily test the theory?

There's no evidence of the tank overflowing - but it's not easy to spot - it's an internal overflow pipe from f&e tank (see photo - I can't remember the proper term for it!).

Between the woodburner and store, there is one valve - normally closed that I understand

opens with the stat on the woodburner (I could be wrong here) (I guess the normally open to the dump also closes as well), and the valve closes when the overheat stat on the store is tripped.

We do have expansion pipe from the woodburner - coming off just before the valve and pump on the feed to the store, so no kettling sounds, which is good.

I've also found the original schematic - that might prove useful. I think we installed true to the schematic.

Thanks.